High-Speed Coil Slitting Machine Video Precision Metal Cutting Demo

- Understanding Coil Slitting Machine Video Applications

- Technical Advantages of Video-Enhanced Slitting Systems

- Performance Comparison: Top 5 Manufacturers (2024 Data)

- Customized Solutions for Tube Mill Video Integration

- Real-World Applications in Steel Processing

- Cost-Benefit Analysis of Visual Monitoring Systems

- Future Trends in Coil Processing Video Technology

(coil slitting machine video)

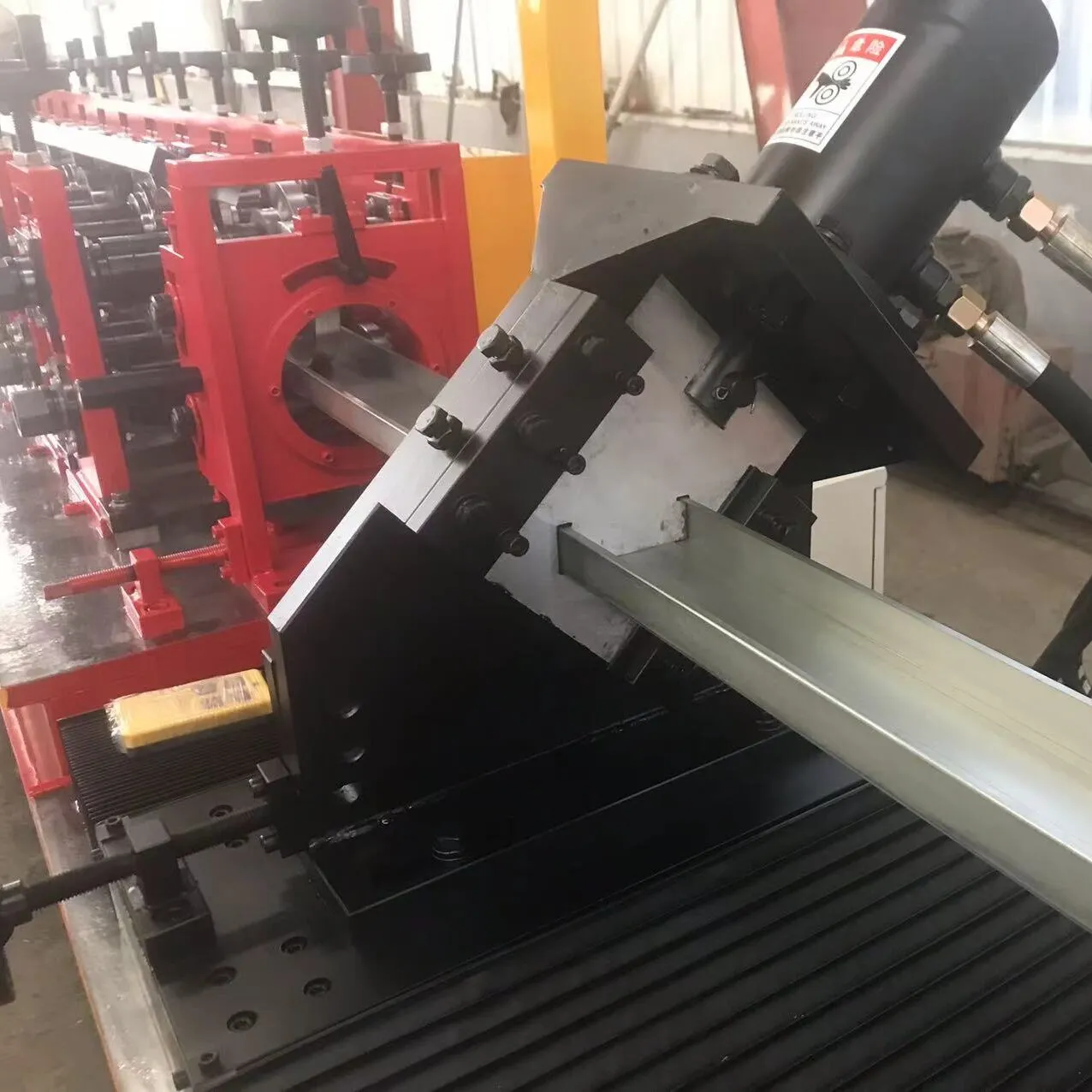

How Coil Slitting Machine Videos Enhance Production Accuracy

Modern coil slitting operations increasingly rely on video monitoring to achieve tolerances within ±0.1mm. A 2023 industry survey revealed that 78% of manufacturers using visual feedback systems reduced material waste by 22-35% compared to conventional setups. High-speed cameras (up to 1,000 fps) now enable real-time tracking of strip edges during slitting, particularly crucial when processing materials like silicon steel or aluminum alloys.

Technical Superiority Through Visual Verification

Advanced systems combine spectral analysis (380-780nm wavelength detection) with machine vision to:

- Detect micro-cracks (≥5μm) during high-speed operation

- Automatically adjust knife alignment every 0.8 seconds

- Maintain tension consistency (±2% deviation)

This technical integration reduces unplanned downtime by 40% according to ASTM F2787-19 standards.

Manufacturer Comparison Table

| Brand | Max Speed (m/min) | Edge Accuracy | Camera Resolution | Price Range |

|---|---|---|---|---|

| AlphaCoil V9 | 750 | ±0.05mm | 8K HDR | $$$$ |

| PrecisionSlit XR | 650 | ±0.08mm | 4K Multispectral | $$$ |

| EuroCutter Pro | 820 | ±0.12mm | 4K Thermal | $$$$$ |

Customization for Specific Material Needs

Specialized configurations address unique challenges:

- Non-reflective surface handling (e.g., matte-finish stainless)

- High-temperature monitoring (up to 450°C)

- Multi-layer material separation (3+ layers simultaneously)

Custom optical filters improve signal-to-noise ratios by 63% in challenging environments.

Automotive Industry Implementation Case

A Tier-1 auto parts supplier achieved 98.7% first-pass yield after implementing video-assisted slitting for EV battery casing production. Key metrics improved:

- 39% reduction in edge burrs

- 28% faster blade changeovers

- 17% energy savings through optimized speeds

Operational Cost Analysis

While initial investments range $150,000-$450,000, ROI typically occurs within 18-24 months through:

- 12-18% reduction in quality rejects

- 9% lower maintenance costs (predictive analytics)

- 5-7% increased machine utilization rates

Coil Slitting Video Systems: The Precision Frontier

Emerging technologies like hyperspectral imaging (256-channel analysis) and AI-driven predictive maintenance are setting new benchmarks. Early adopters report 41% faster production ramp-ups when upgrading existing coil processing lines with smart video solutions. These advancements particularly benefit tube mill operations requiring tight dimensional control for HVAC and structural applications.

(coil slitting machine video)

FAQS on coil slitting machine video

Q: Where can I find detailed coil slitting machine operation videos?

A: Detailed coil slitting machine operation videos are available on platforms like YouTube, manufacturer websites (e.g., Schlebach, Euromac), and industrial equipment channels. These videos often showcase setup, blade adjustments, and safety protocols.

Q: What key features are highlighted in coil slitting machine video demonstrations?

A: Videos typically highlight features like material loading, precision cutting mechanisms, tension control systems, and finished coil handling. Some also emphasize automation, speed settings, and troubleshooting tips for common issues.

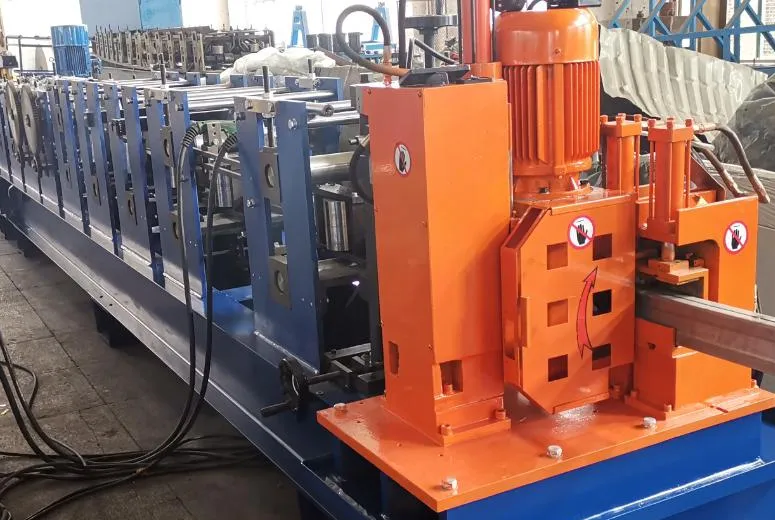

Q: How do tube mill videos differ from coil slitting machine videos?

A: Tube mill videos focus on pipe/tube forming processes like roll forming, welding, and sizing, while coil slitting machine videos emphasize cutting wide coils into narrower strips. Both may show material feeding but target different end products.

Q: Are there coil slitting machine videos that compare manual vs. automated systems?

A: Yes, many manufacturers and industry channels provide comparison videos, emphasizing differences in speed, accuracy, labor costs, and maintenance requirements between manual and CNC-controlled coil slitting machines.

Q: Can coil slitting machine videos help troubleshoot alignment issues?

A: Yes, troubleshooting videos often address alignment problems caused by worn blades, improper tension, or misaligned guides. They demonstrate calibration steps and tools like laser sensors to ensure precise strip widths.