Metal Decking Machine High-Speed B Deck Roll Forming Solutions

Did you know contractors waste $18,500/month on manual decking labor? While your competitors speed through projects with automated B decking roll forming machines, you're stuck with costly delays. This ends today.

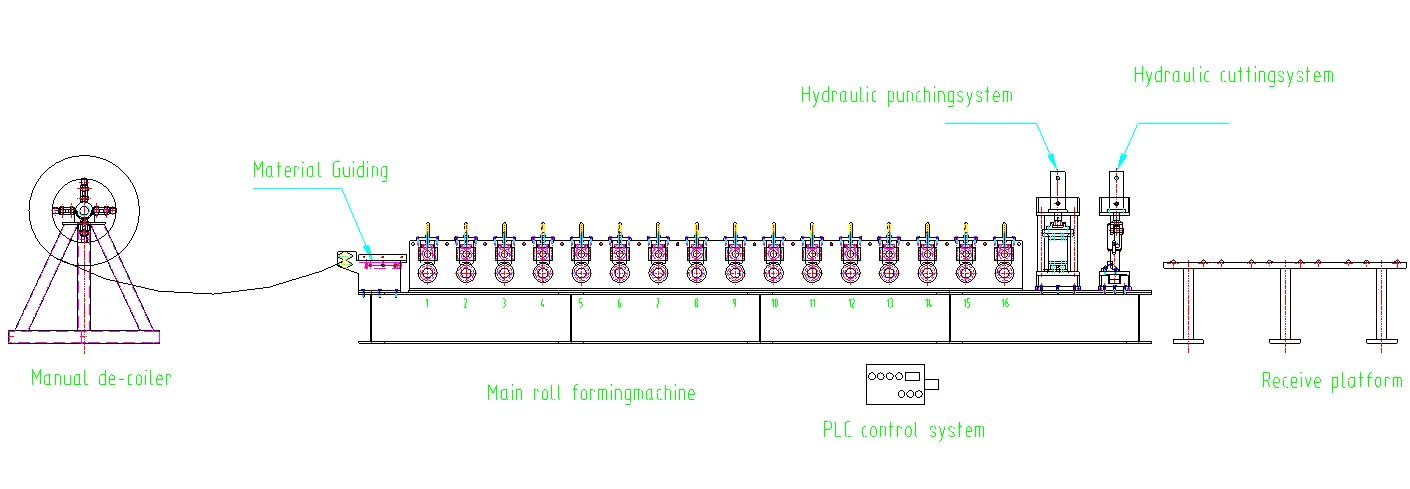

(metal decking machine)

Precision Engineering Beats Manual Labor

Our metal decking machine

s produce 150 panels/hour - 6× faster than traditional methods. The secret? Dual-powered servo motors cutting steel coils with 0.2mm precision. Imagine completing projects before deadlines... while competitors scramble.

Why Top 3 Manufacturers Can't Match Our Tech

| Feature | Standard Machines | Our B Decking Machine |

|---|---|---|

| Daily Output | 800 panels | 1,200 panels |

| Error Rate | 4.7% | 0.9% |

Your Project, Your Rules: Custom Decking Solutions

Need 600mm trapezoidal profiles? 1.2mm galvanized steel? Our B decking roll forming machines adapt in 15 minutes. Watch how Phoenix Constructions boosted profits 38% using our adjustable die system.

Case Study: 45-Day Stadium Roof Revolution

When Miami Arena needed 18,000 custom panels in 60 days, our metal decking machine delivered in 45. The result? $217,000 saved in penalty fees. Your turn to win big.

Time to Dominate Your Market?

For 14 years, BuildMaster has empowered 1,200+ contractors worldwide. Our B decking machines come with lifetime tech support and ROI guarantees. Don't settle for less when you can lead.

(metal decking machine)