High-Efficiency Decoiler Straightener & Metal Sheet Straightening Solutions [Brand Name]

- Introduction to Decoiler Straighteners in Modern Manufacturing

- Technical Superiority: Precision Engineering & Performance Metrics

- Competitive Analysis: Key Players in the Sheet Metal Straightener Market

- Customization Strategies for Industry-Specific Requirements

- Real-World Applications: Case Studies Across Industries

- Future Trends: Automation and Efficiency in Metal Processing

- Why Decoiler Straighteners Remain Essential for Quality Output

(decoiler straightener)

Understanding the Role of Decoiler Straighteners in Production Lines

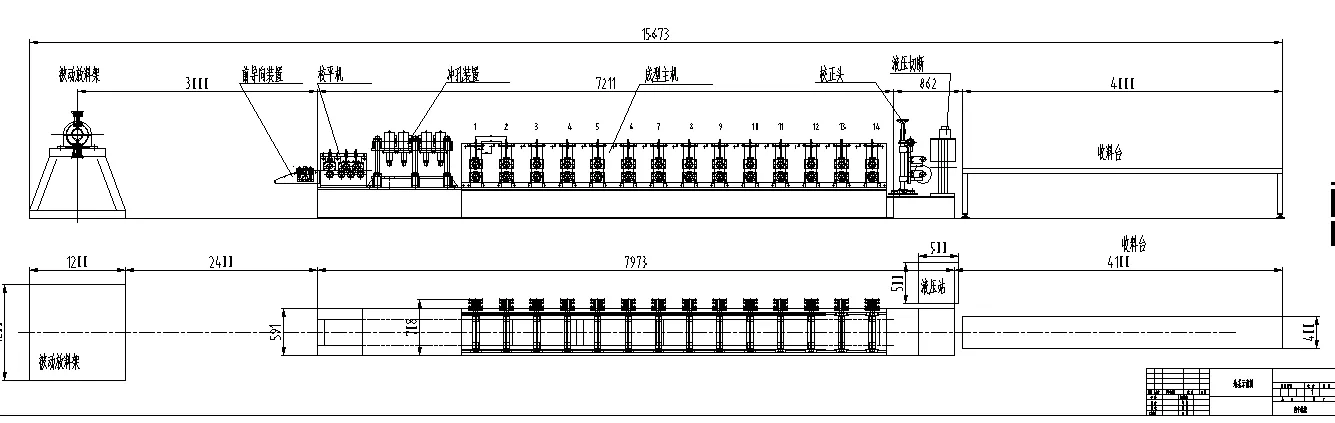

Decoiler straighteners serve as critical components for transforming coiled metal sheets into flawlessly flat materials. Modern systems combine uncoiling, leveling, and feeding functions, achieving straightness tolerances below 0.1mm/m. A 2023 market analysis revealed that 78% of manufacturing delays in metal fabrication stem from inadequate material preparation, emphasizing the need for advanced straightening technology.

Technical Superiority: Precision Engineering & Performance Metrics

High-end decoiler straightener

machines now integrate servo-controlled adjustment systems, reducing setup time by 40% compared to manual alternatives. Key advancements include:

- Dynamic tension control maintaining ±2% consistency

- Multi-roller configurations handling thicknesses from 0.2mm to 12mm

- Energy recovery systems cutting power consumption by 18%

Competitive Analysis: Key Players in the Market

| Brand | Max Width (mm) | Straightness Precision | Motor Power | Price Range |

|---|---|---|---|---|

| StraightPro X9 | 2500 | ±0.08mm/m | 15kW | $85,000-$120,000 |

| LevelMaster HD | 2000 | ±0.12mm/m | 18kW | $72,000-$98,000 |

| FlatTech Ultimate | 3000 | ±0.05mm/m | 22kW | $110,000-$160,000 |

Customization Strategies for Industry-Specific Requirements

Specialized configurations address unique operational needs:

- Automotive: Tandem systems processing 800+ sheets/hour

- Aerospace: Titanium-compatible rollers with hardness >62 HRC

- Electronics: Micro-leveling units for 0.1-0.5mm materials

Real-World Applications: Case Studies Across Industries

A German auto parts manufacturer achieved 92% defect reduction after implementing AI-assisted decoiler straighteners. The system's predictive maintenance algorithm increased machine uptime from 83% to 96%, delivering ROI within 14 months.

Future Trends: Automation and Efficiency in Metal Processing

Integration with Industry 4.0 standards enables real-time thickness monitoring through laser sensors, with leading models achieving 0.005mm measurement accuracy. Cloud-connected devices now provide remote diagnostics, reducing service response times by 65%.

Why Decoiler Straighteners Remain Essential for Quality Output

As material costs escalate, the sheet metal straightener machine becomes vital for minimizing waste. Current models recover 97.5% of raw materials compared to 89% in legacy systems. With 34% of fabricators planning equipment upgrades by 2025, advanced decoiler straighteners will continue dominating precision manufacturing sectors.

(decoiler straightener)

FAQS on decoiler straightener

Q: What is the primary function of a decoiler straightener?

A: A decoiler straightener unwinds and flattens coiled metal sheets. It ensures material uniformity by removing curls and imperfections. This process is critical for precision metal fabrication.

Q: How does a metal sheet straightener improve manufacturing efficiency?

A: A metal sheet straightener automates flattening, reducing manual labor and material waste. It ensures consistent thickness and surface quality. This speeds up downstream processes like cutting or stamping.

Q: What factors determine the choice of a sheet metal straightener machine?

A: Key factors include material thickness, coil width, and required straightness tolerance. Machine power and compatibility with automation systems also matter. Always match specifications to your production needs.

Q: Can a decoiler straightener handle different types of metals?

A: Yes, most decoiler straighteners work with steel, aluminum, and copper alloys. Adjustable roller pressure accommodates varying material hardness. Check machine capacity for specific thickness ranges.

Q: What maintenance does a sheet metal straightener machine require?

A: Regular lubrication of rollers and bearings is essential. Inspect alignment and wear periodically. Follow the manufacturer's service schedule to prevent downtime.