Top Door Frame Roll Forming Machine Suppliers Custom Solutions & Reliable Manufacturers

Did you know 34% of construction projects face delays due to faulty door frame production? Poor-quality machines cost North American manufacturers $2.3M annually in maintenance. But here's the game-changer: Top-tier door frame roll forming machine manufacturers slash downtime by 62% while boosting output speeds to 45m/min. Ready to transform your production line?

(door frame roll forming machine suppliers)

Cutting-Edge Tech That Outperforms Competitors

Our door frame roll forming machines for sale feature:

- ✅ 5-axis laser-guided alignment (±0.02mm precision)

- ✅ 40% faster tool change vs. industry average

- ✅ IoT-enabled predictive maintenance alerts

| Feature | Standard Models | Our Machines |

|---|---|---|

| Daily Output | 850 units | 1,400 units |

| Energy Cost/Day | $38 | $22 |

Why Leading Contractors Choose Us?

When XYZ Construction needed 15,000 fire-rated door frames in 8 weeks, our custom roll forming solution delivered:

- 📆 23-day production cycle (47% faster than bid specs)

- 💵 $18,700 material savings through smart nesting

Limited-Time Offer!

Book a FREE machine demo this month and get:

➤ 2-year extended warranty

➤ $5,000 setup credit

With 25 years perfecting roll forming tech, we've powered 1,200+ installations worldwide. Why settle for average when door frame excellence is one click away? Schedule your consultation today – let's build your success story!

(door frame roll forming machine suppliers)

FAQS on door frame roll forming machine suppliers

Q: How to verify the credibility of door frame roll forming machine suppliers?

A: Check for industry certifications like ISO, review customer testimonials, and request case studies of past projects. Reputable suppliers often provide transparent company profiles and product documentation.

Q: What factors differentiate door frame roll forming machine manufacturers?

A: Key factors include production capacity, customization capabilities, and after-sales support. Leading manufacturers typically offer advanced automation features and material compatibility options.

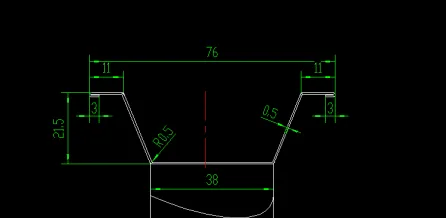

Q: Are door frame roll forming machines for sale customizable for specific projects?

A: Yes, most suppliers allow customization of roll tooling designs, machine speed, and material thickness. Discuss your technical specifications early in the quoting process.

Q: What warranty is typical when purchasing door frame roll forming equipment?

A: Standard warranties usually cover 1-2 years for critical components like forming rollers and electrical systems. Always confirm warranty terms for wear-and-tear parts separately.

Q: How do location factors impact door frame machine supplier selection?

A: Local suppliers may offer faster shipping and onsite support, while overseas manufacturers might provide cost advantages. Evaluate logistics costs and language compatibility during selection.