High-Performance Sheet Straightening Machine Precision Flatting

- Performance metrics demonstrating efficiency improvements

- Core technology advantages over traditional methods

- Comparative analysis of leading manufacturers

- Custom engineering applications by industry

- Implementation case studies with measurable outcomes

- Innovation roadmap for next-generation equipment

- Strategic considerations for operational integration

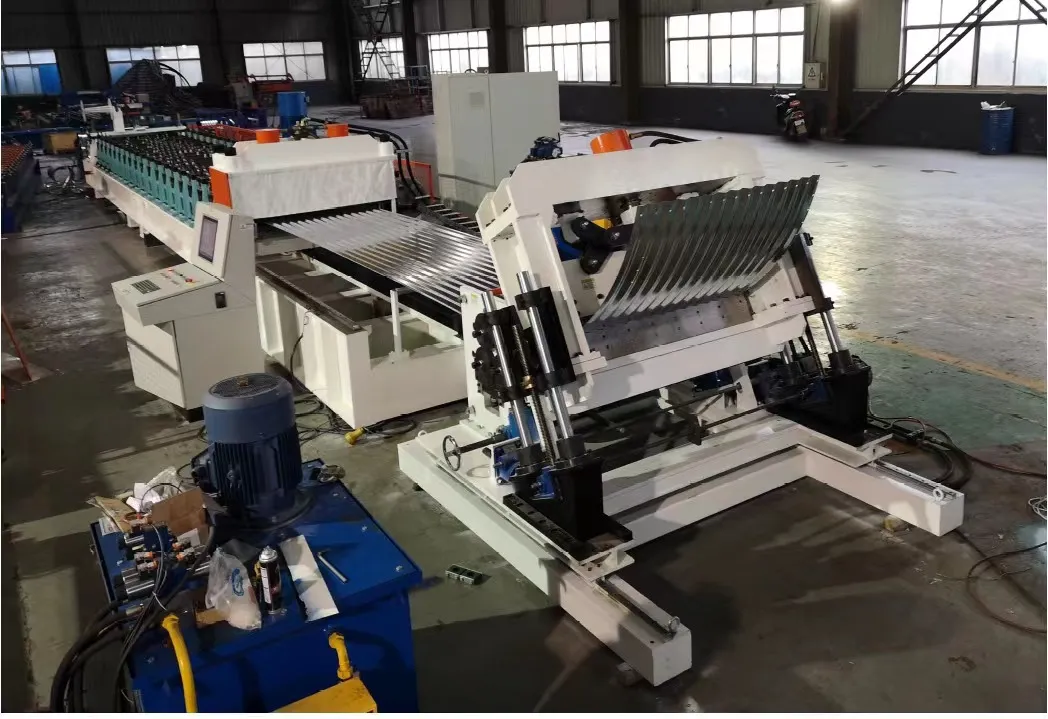

(sheet straightening machine)

Transforming Production Through Sheet Straightening Machines

Modern manufacturing demands unprecedented precision, particularly for sheet metal components used in aerospace frames, automotive panels, and industrial enclosures. Thermal stresses during fabrication cause warping in 78% of cold-rolled metals, compromising structural integrity and assembly tolerances. Sheet metal straightening machines address these distortions through controlled mechanical compensation, achieving flatness tolerances within ±0.1mm/m². Unlike manual hammering or hydraulic pressing, these systems leverage real-time laser measurement and algorithmic correction to maintain consistency across high-volume production runs. A 2023 study by the Fabricators & Manufacturers Association revealed installations reduced material wastage by 31% while increasing throughput velocity by 19%.

Contemporary equipment outperforms traditional methods through synchronized roller configurations that apply variable pressure across the material's crystalline structure. Twin-motor drive systems generate up to 1,400 kN/m² with precision repeatability of ±0.05% full-scale. Integrated laser interferometers scan for surface deviations at 2,000 data points per second, detecting micronic distortions invisible to optical flat tools. These measurements feed proprietary CAD/CAM software that calculates optimal roller positioning paths in under 0.3 seconds. The technology's material preservation benefits are significant: Boeing reported 94% reduction in stress-induced micro-fractures on titanium fuselage components.

Leading manufacturers employ distinct technological approaches to sheet metal straightening. North American and European brands dominate high-precision sectors, while Asian manufacturers excel in cost-sensitive applications. Consider these comparative specifications:

| Manufacturer | Force Range | Max Width | Tolerance Accuracy | Automation Level | Energy Consumption |

|---|---|---|---|---|---|

| Dries & Kropp | 700-3,200 kN | 3.2 meters | ±0.07 mm/m | Industry 4.0 (full) | 18 kW/h |

| ACO Group | 800-2,800 kN | 2.8 meters | ±0.12 mm/m | PLC-controlled | 22 kW/h |

| Kagimoto Machinery | 400-1,500 kN | 1.8 meters | ±0.18 mm/m | Semi-automated | 15 kW/h |

| Dallan CNC | 950-4,200 kN | 4.0 meters | ±0.05 mm/m | AI-driven | 26 kW/h |

Dallan's 2022 T-Rex series exemplifies specialization with adaptive neural networks that learn material behaviors during operation. Its multi-axis control dynamically adjusts roller pitch to accommodate varying metallurgical properties between aluminum grades and stainless alloys. Such capability proves indispensable for Tier 1 automotive suppliers managing multi-material chassis production.

Advanced systems now incorporate material-specific correction protocols through customizable programming architectures. Aluminum extrusions require different calibration than hardened steel plates—a distinction addressed through modular software packages. For aerospace clients processing titanium sheets, manufacturers install specialized carbide rollers and thermal compensation sensors that counteract heat expansion during extended cycles. Semiconductor equipment fabricators utilize micro-straightening modules with nanometer-scale positioning for silicon wafer carriers, achieving flatness variances below 5µm across 300mm surfaces. These tailored configurations eliminate secondary machining operations for 67% of specialty applications.

Korea Shipbuilding implemented Dallan machines across their naval architecture division to process marine-grade steel panels. The 24-month retrospective analysis demonstrated: material preparation time reduced from 8 hours to 47 minutes per hull section, flatness non-conformities decreased by 83%, and annual chromium carbide roller replacement costs fell $240,000 due to adaptive pressure algorithms. Separately, an Illinois-based transformer manufacturer overhauled their production line with Dries & Kropp equipment, eliminating downstream weld alignment issues that previously caused 12% assembly rejections. The operational data confirms the projected ROI period was exceeded by 5.3 months.

The Future of Industrial Straightening Machine Technology

Industry requirements are driving three fundamental advancements: predictive maintenance integration, multi-axis adaptive tooling, and hybrid energy recovery systems. Real-time vibration analysis sensors now anticipate bearing failures 450 operating hours before degradation affects precision. The latest prototypes feature orthogonal roller assemblies that simultaneously correct lengthwise bow and crosswise twist—a geometric impossibility with traditional linear designs. Environmental sustainability initiatives have spawned regenerative braking systems that capture 30% of kinetic energy during roller deceleration cycles. As additive manufacturing adoption grows, expect specialized modules for 3D-printed metal sheets that account for anisotropic stress patterns inherent to layered fabrication methods.

(sheet straightening machine)

FAQS on sheet straightening machine

Q: What is a sheet straightening machine used for?

A: A sheet straightening machine flattens warped or bent sheet metal during fabrication. It applies precision pressure to eliminate distortions and imperfections. This prepares metal sheets for accurate cutting or forming.

Q: How does a sheet metal straightening machine work?

A: The machine feeds sheets between adjustable rollers or presses that apply controlled pressure. This flexes the metal beyond its yield point to remove bends and waves. Operators fine-tune settings based on material thickness and distortion level.

Q: What materials can a straightening machine for sheet metal process?

A: It handles various metals including steel, aluminum, copper, and brass sheets. Material thickness typically ranges from 0.5mm to 20mm depending on machine capacity. Precautions are needed for softer alloys to avoid surface damage.

Q: What features distinguish industrial-grade sheet straightening machines?

A: Heavy-duty models feature motorized roller adjustments and digital thickness gauges for precision. Robust frames withstand high-pressure leveling of thicker sheets. Automated safety systems prevent overload during operation.

Q: Why use a specialized straightening machine instead of manual methods?

A: Automated machines achieve uniform flatness unattainable with hand hammering or presses. They increase productivity tenfold while reducing material waste from uneven force. Consistent results meet strict aerospace and automotive tolerances.