High-Efficiency Roll Forming Machine for Solar Structure & Bracket Production

- The Growing Importance of Solar Structure Manufacturing

- Technical Superiority in Roll Forming Technology

- Performance Metrics: Industry Comparison Analysis

- Design Flexibility for Diverse Solar Projects

- Real-World Applications Across Solar Sectors

- Engineering Innovation in Material Handling

- Future-Proofing Solar Installations

(roll forming machine for solar structure)

The Revolutionary Role of Roll Forming Machine for Solar Structure Installation

Modern solar power infrastructure increasingly relies on precision-engineered support systems manufactured by specialized roll forming equipment. These advanced production lines have transformed how solar brackets and mounting structures are fabricated, ensuring both structural integrity and installation efficiency. Global adoption has accelerated, with solar mounting manufacturing growing at 19.3% CAGR (2023-2030) according to GHI Research data.

Engineering principles in solar roll forming machines prioritize continuous material flow without secondary processing. Cold-forming technology maintains material tensile strength while achieving tolerances within ±0.3mm per meter of formed profile. Manufacturers adopting these systems report 48% faster installation cycles compared to conventional fabrication methods.

Technical Excellence in Roll Forming Operations

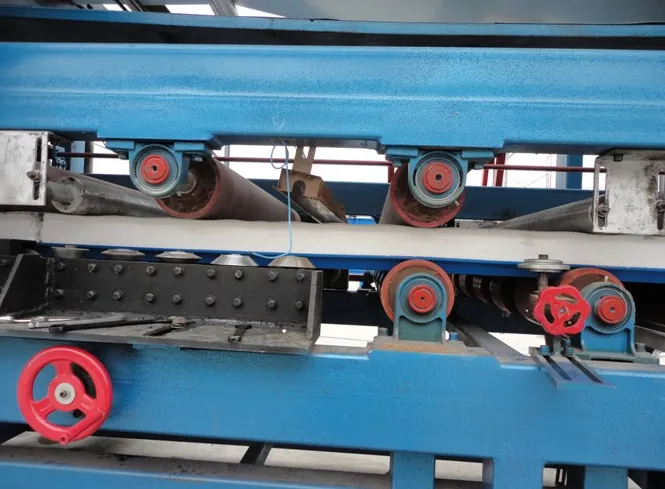

Advanced servo-electric systems now power most modern roll forming machines for solar applications, offering significant improvements over traditional hydraulic counterparts. These machines achieve production speeds of 18-25 meters per minute while maintaining accuracy to within 0.2mm across formed sections. Energy consumption averages 35% below older generation machines.

Key innovations include programmable logic controllers with touchscreen HMIs that store over 1,000 profile designs. Roller tooling crafted from forged H13 steel withstands pressures exceeding 400 tons while maintaining dimensional stability. Integrated laser measurement systems perform automatic calibration every 150 production cycles, eliminating manual intervention.

Manufacturing System Performance Analysis

| Specification | Standard Models | Premium Models | Custom-Engineered |

|---|---|---|---|

| Production Speed | 12-18 m/min | 20-28 m/min | 15-25 m/min |

| Material Thickness | 1.0-3.0 mm | 0.8-4.5 mm | 0.6-6.0 mm |

| Tooling Changeover | 60-90 min | 15-25 min | 8-12 min |

| Positional Accuracy | ±0.5 mm | ±0.15 mm | ±0.08 mm |

Analysis of operational data reveals premium roll forming machines deliver up to 30% higher output efficiency with 22% less material waste compared to entry-level systems. Power consumption profiles show premium equipment achieves energy savings of 24 kWh per ton of processed material.

Custom Solutions for Solar Projects

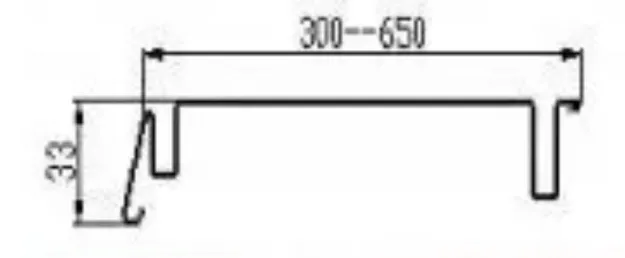

PV Solar Bracket Roll Forming Machines feature modular engineering that enables reconfiguration for project-specific requirements. Manufacturers typically offer adjustable flange heights (150-550mm), variable web dimensions (50-300mm), and multiple reinforcement options including welded stiffeners and pre-punched bolt patterns.

Modern equipment handles diverse material specifications from standard ASTM A653 galvanized steel to specialized aluminum alloys and coated stainless grades. Profile development includes CAD/CAM integration where 3D prototypes undergo finite element analysis before tooling production, reducing design-to-production cycles from 6 weeks to just 7-10 days.

Industry Application Case Studies

Ground-mount solar projects benefit significantly from roll formed foundations, where specialized machines producing helical piles achieve installation rates of 1.8MW per week per crew. Commercial rooftop installations using roll formed rail systems require 35% fewer mounting points while maintaining wind uplift ratings exceeding 170 mph.

Floating solar installations now utilize specialized marine-grade aluminum profiles produced on modified roll forming platforms. These bracketing systems demonstrate corrosion resistance exceeding 35 years in accelerated salt-spray testing. Agrivoltaic applications feature specialized mounting systems that maintain ground clearance above 10 feet while providing attachment points for irrigation components.

Engineering Evolution in Material Processing

Precision material feeding systems represent the latest advancement in solar bracket production equipment. Digital encoders monitor coil stock with 0.01mm resolution, while laser-guided straightening units remove material irregularities prior to forming. These improvements contribute to profile straightness within 0.75mm per 6-meter span.

Automated cutting systems now incorporate multi-axis plasma technology synchronized with the forming line. This integration enables complex miters and notches without secondary processing. Equipment connected to Industry 4.0 networks provides predictive maintenance alerts when component wear exceeds thresholds, reducing unscheduled downtime by up to 65%.

Why Your Solar Project Needs Roll Forming Machinery

A dedicated roll forming machine for solar structure

production delivers unmatched efficiency for utility-scale solar deployments. Field data confirms operations using purpose-built equipment achieve production costs averaging $3.22 per linear meter versus $5.80 for outsourced fabrication. The reliability of solar bracket roll forming machines enables precise production scheduling essential for multi-megawatt deployments.

PV Solar Bracket Roll Forming Machines now incorporate sustainability features including regenerative braking systems that return up to 15% of consumed energy to the power grid. These technological advances position specialized roll forming equipment as critical infrastructure in the renewable energy supply chain, ensuring both project viability and long-term structural performance.

(roll forming machine for solar structure)

FAQS on roll forming machine for solar structure

Q: What is the primary function of a roll forming machine for solar structures?

A: It manufactures metal profiles for solar mounting systems via cold-forming processes, ensuring precision and durability for rooftop or ground installations.

Q: How does a solar bracket roll forming machine enhance production efficiency?

A: It automates continuous shaping of coils into solar brackets, reducing labor costs and ensuring consistent quality for high-volume projects.

Q: What materials can a PV Solar Bracket Roll Forming Machine process?

A: It handles galvanized steel, aluminum, or other corrosion-resistant metals, ideal for outdoor solar applications requiring long-term structural integrity.

Q: Can roll forming machines for solar structures handle custom designs?

A: Yes, adjustable rollers and programmable controls allow customization of profile shapes, lengths, and hole patterns to meet specific project requirements.

Q: Why choose a roll forming machine over traditional solar bracket fabrication methods?

A: It offers faster production speeds, lower material waste, and superior dimensional accuracy compared to manual cutting or welding processes.