|

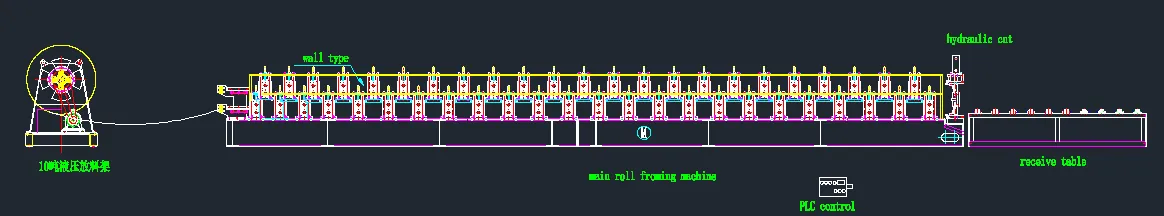

1.5Ton manual decoiler *2

1.Inner dia: Ø440mm– Ø560mm

2.Max input pascens: 1250mm

3.Capacity: 5Tons

4.Coil diameter max1300 mm

5.Material:Aluminum and zinc plate galvanized plate color steel plate low carbon steel

|

|

|

Ratio pascendi

Input corrigere accommodare per 1250mm.Change magnitudine facile

|

|

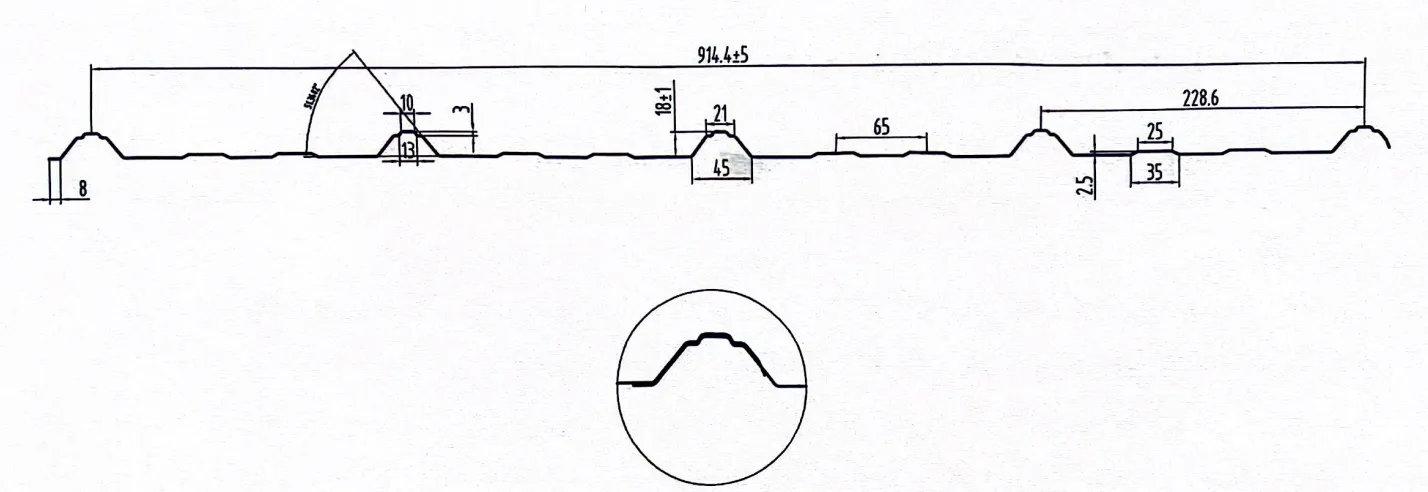

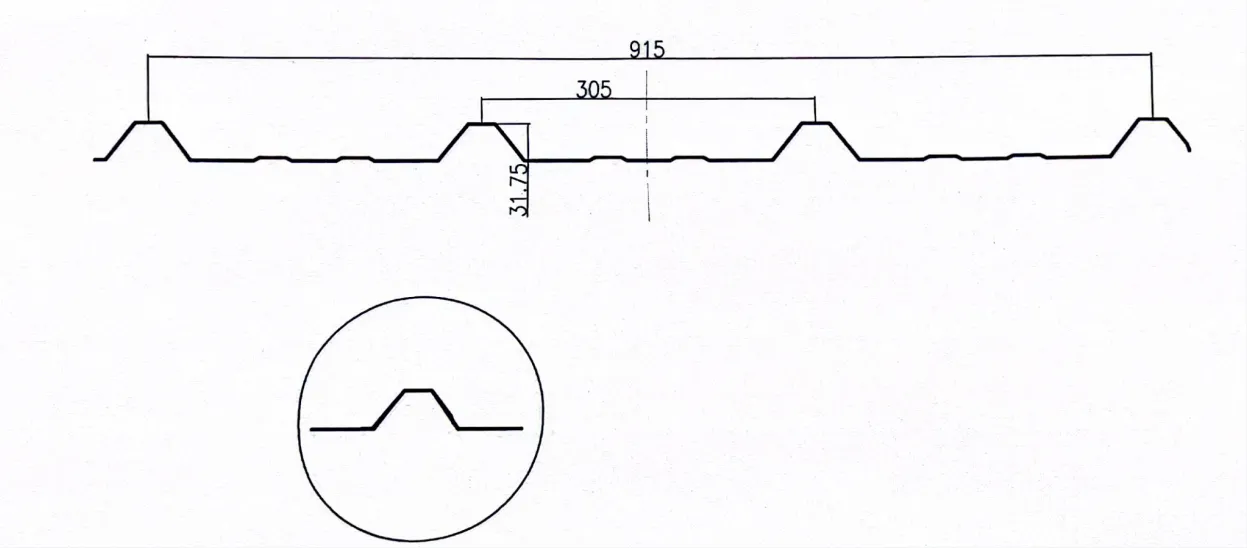

Duplex tabulatum volumen formans machinam

1.Matching materia: lamina cum flexione armorum colorata intensio Q195-235.

2.Material crassities: 0.3-1.0mm

- Power: 11kwhydraulic station power:5.5kw

4.. celeritatem formans: 0-25 m/min

- 5. Stationes Roll: 14/16

- 6. Material et diametri Shaft: materia est Cr 40, ¢80mm

- 7. Tolerantia: +-1.5mm

- 8. Via coegi: catena

- Systema moderantum: PLC

- 10. Voltage: 220v ,60hz ,3ph

- 11. Materia globulos formandi: 45# Curatio caloris et chromedae.

- 1Material of cultri ferrarii: Cr 12 ferrum fingunt exstincto curationis HRC58-62

|

|

|

Hydraulica sectione

1.Cutting motus: Machina principalis automatice subsistit ac deinde inciditur. Post sectionem, machina principalis statim incipiet.

2.Material of ferrum: GCR12 cum calor curatio

3.Length mensuræ: Lorem longitudinem mensurae

4.Tolerance longitudinis: 10+/- 1.5mm

|

- PLC imperium systema

-

1.Automatic longitudo mensurae

2.Automatic quantitas mensurae

3.Computer temperare solebat longitudinem & quantitatem. Machina sponte secare ad longitudinem et desine cum quantitas requiritur

4.Length indiligentia facile emendari potest

5.Control panel: Button-type switch and touch screen

6.Unit longitudinis: millimeter (switched in the control panel)

|

|

-

|

Negotium dicta:

Warranty: 12 menses a partu.

Payment term: 30% depositum, 70% statera ante naviculas.

Offer validitatem: 50 dies.

Producing time: 45 days.

Installation localiter consilium: emptio praeest sumptus pro unoquoque fabrum. Comprehendo: tesseras aeris circum-trinus , accommodatio et $100/die.

|