|

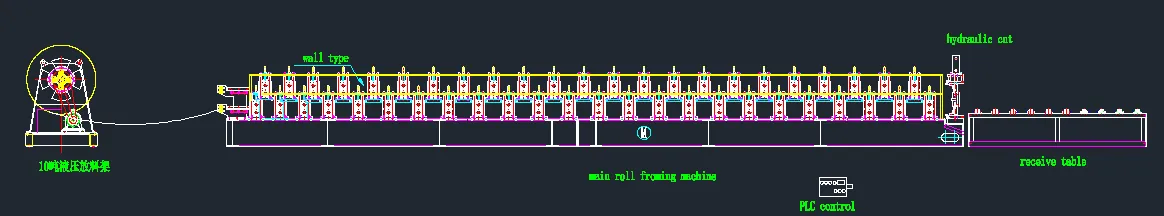

1.5Ton manual decoiler *2

1.Inner dia: Ø440mm– Ø560mm

2.Max input feeding: 1250mm

3.Capacity: 5Tons

4.Coil outer diameter max1300 mm

5.Material:Aluminum and zinc plate galvanized plate color steel plate low carbon steel

|

|

|

Feeding system

Input straighten adjust by 1250mm.Change size easily

|

|

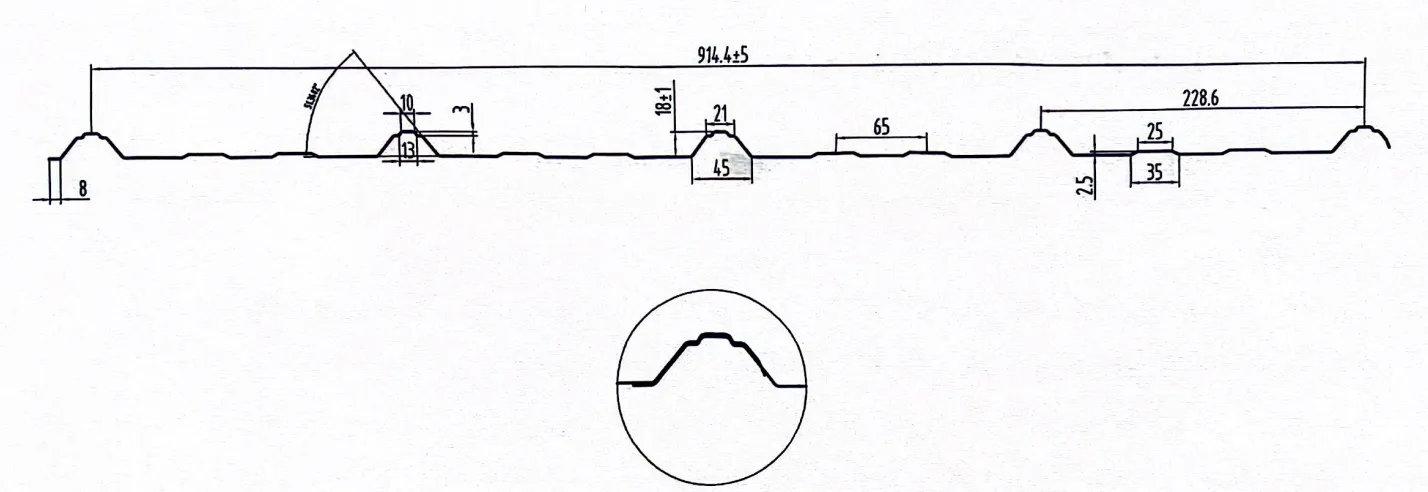

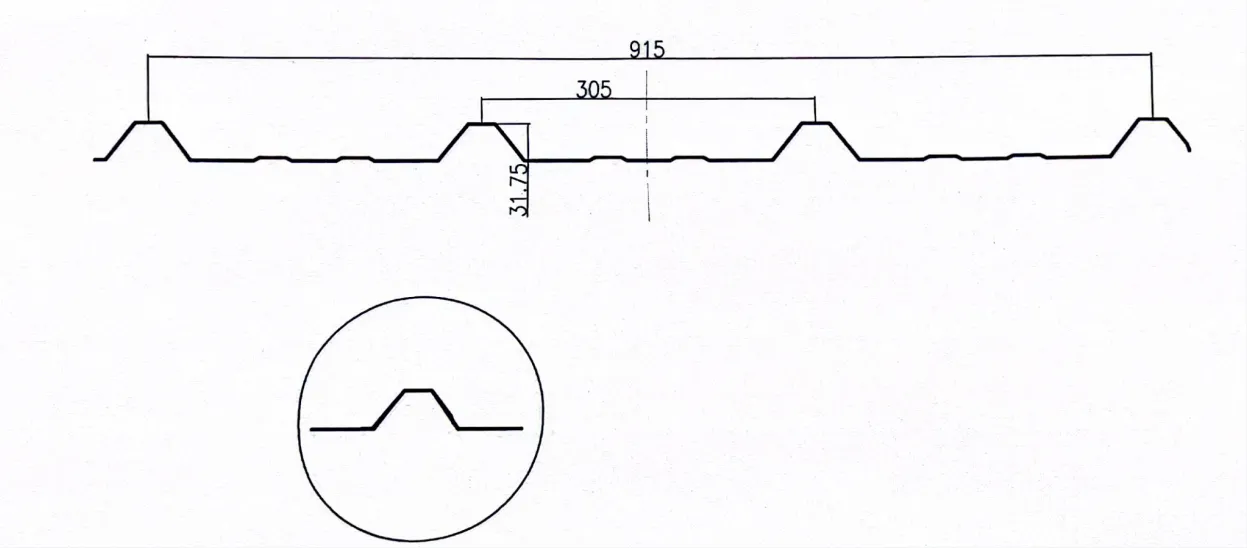

Double layer roll forming machine

1.Matching material: colored armor plate with the bending intensity of Q195-235 .

2.Material thickness: 0.3-1.0mm

- Power: 11kwhydraulic station power:5.5kw

4.. Forming speed: 0-25 m/min

- 5. Roll stations: 14/16

- 6. Shaft Material and diameter: material is Cr 40, ¢80mm

- 7. Tolerance: +-1.5mm

- 8. Way of drive: chain

- Controlling system: PLC

- 10. Voltage:220v ,60hz ,3ph

- 11. Material of forming rollers: 45# heat treatment and chromed.

- 1Material of cutter blade: Cr 12 mould steel with quenched treatment HRC58-62

|

|

|

Hydraulic cutting

1.Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start.

2.Material of blade: GCR12 with heat treatment

3.Length measuring: Automatic length measuring

4.Tolerance of length: 10+/- 1.5mm

|

- PLC control system

-

1.Automatic length measurement

2.Automatic quantity measurement

3.Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

4.Length inaccuracy can be amended easily

5.Control panel: Button-type switch and touch screen

6.Unit of length: millimeter (switched on the control panel)

|

|

-

|

Business remarks:

Warranty: 12 months since delivery.

Payment term:30% deposit, 70% balance before shipping.

Offer validity: 50 days.

Producing time: 45 days.

Installation locally policy: purchase takes in charge of the cost for each engineer. Included: round-trip air tickets , accommodation and $100/day.

|