Our Steel Roof Sheet Roll Forming Machine boasts a robust construction, ensuring longevity and reliability in various working conditions. With a production output of up to 300 sheets per hour, it significantly enhances your productivity, allowing you to meet tight deadlines without compromising on quality. The machine is equipped with advanced technology that ensures consistent thickness and perfect dimensions for every sheet, making it ideal for both residential and commercial roofing projects.

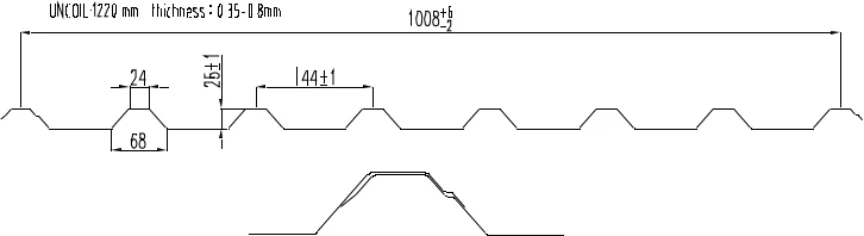

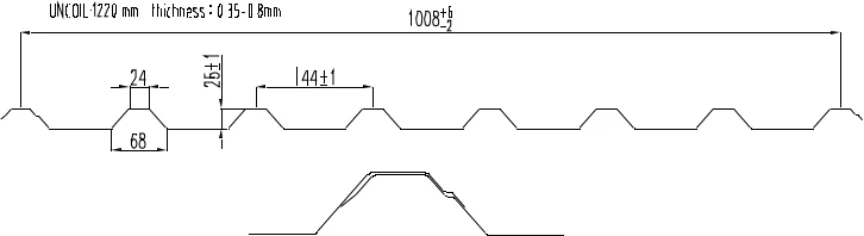

Drawings

Working Process

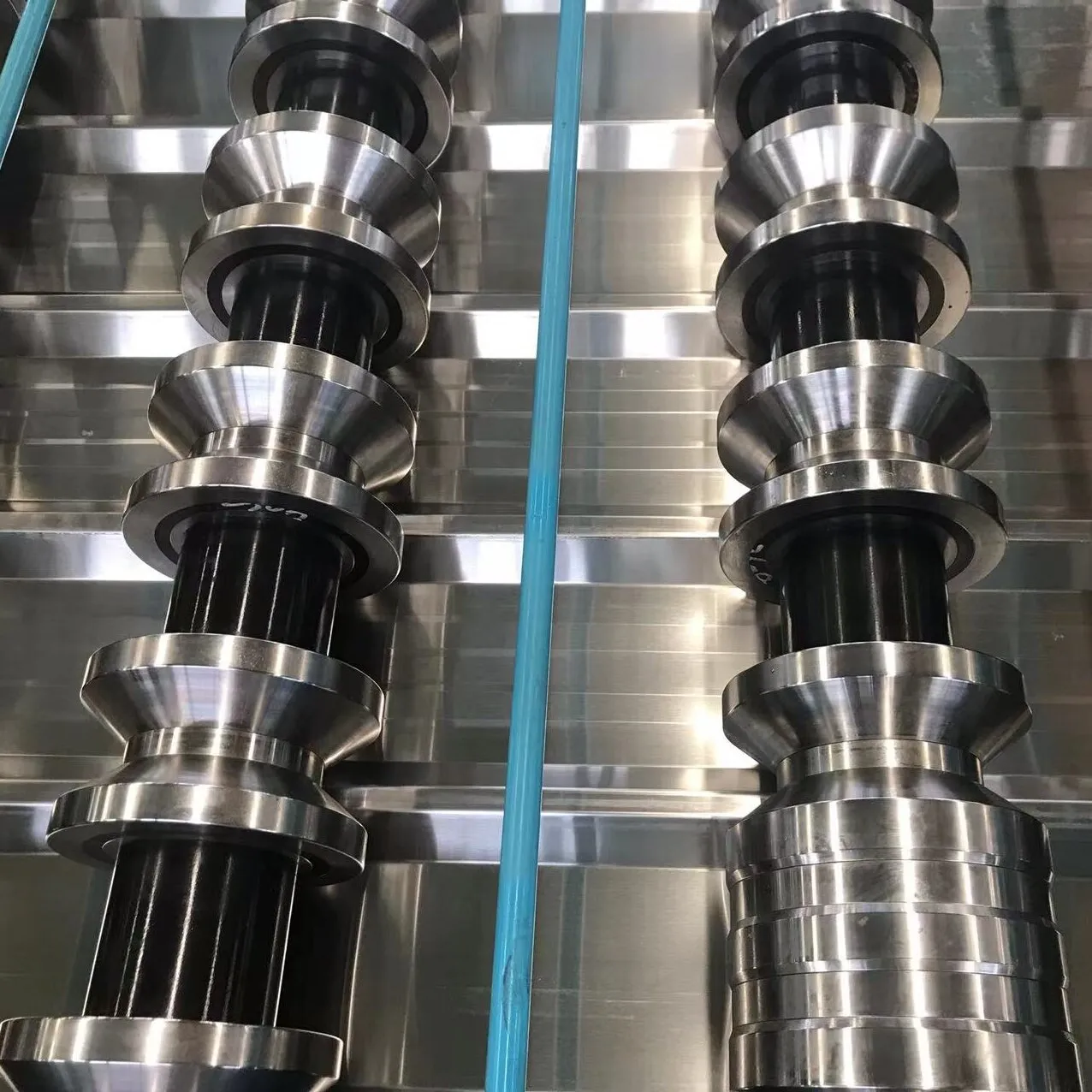

Component

| Manuel De-coiler |

x1 set |

| Main roll forming machine |

x1 set |

| Hydraulic cutting system |

x1 set |

| Hydraulic station |

x1 set |

| PLC Control system |

x1 set |

| Collection table |

x1 set |

|

I.Decoiler

1: Max width of raw material :1300mm

2: Capacity: 5000kgs

3: Inner diameter of coil: 450-600mm

|

|

|

- II.Roll forming machine

- Material thickness range:4-1mm

- Main motor power:5.5kw

- Hydraulic station:3 kw

- 4. Speed:15m/min

- 5. Quantity of rollers:14rollers

- Material of rollers: 45# with chromed

- 7. Shaft Material and diameter: ¢70mm, material is 45# forge steel

- 8.The body of machine: 350H

- 9.Tolerance: 10m+-1.5mm

- Way Of Drive: Chain

- Control system: PLC

-

|

- III.Cutting

Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start.

- Material of blade: Cr12 mould steel with quenched

treatment 58-62℃

Length measuring: Automatic length measuring

Tolerance of length: 10+/- 1.5mm

|

|

|

- IV.PLC control system

- Voltage, Frequency, Phase: 380V, 50 Hz, 3Phase

- Automatic length measurement:

- Automatic quantity measurement

- Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

- Length inaccuracy can be amended easily

- Control panel: Button-type switch and touch screen

- Unit of length: millimeter (switched on the control panel)

-

|

|

V.Collection table

Effective length:6M (standard)

|

|