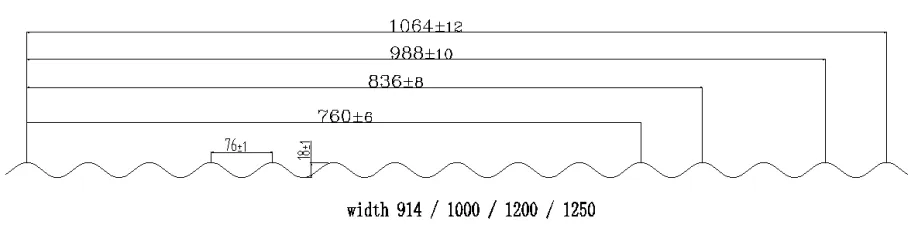

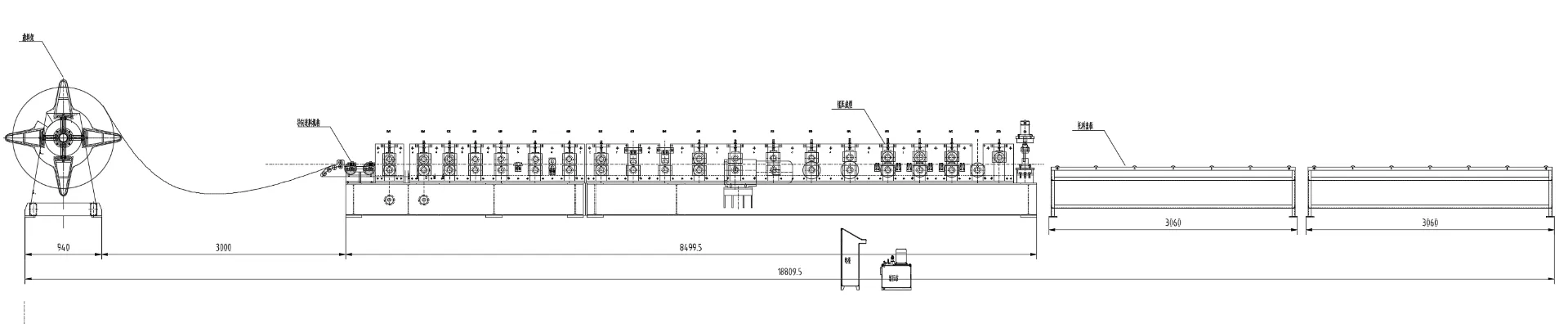

Drawings

Processes and components

| Manuel decoiler | x 1 set |

| Guiding and feeding system | x 1 set |

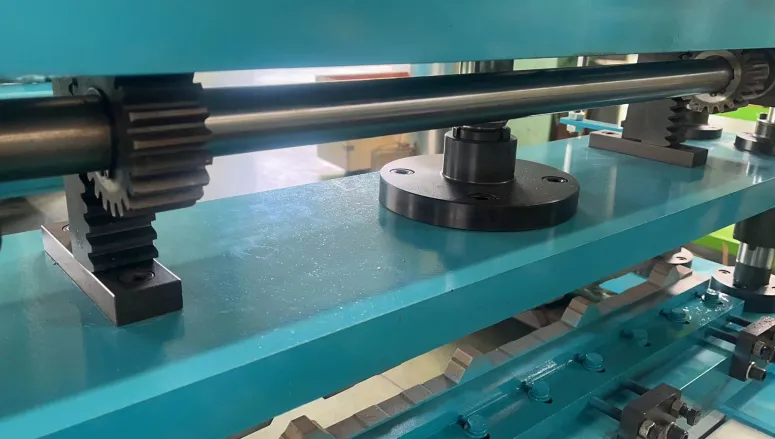

| Main roll forming machine | x 1 set |

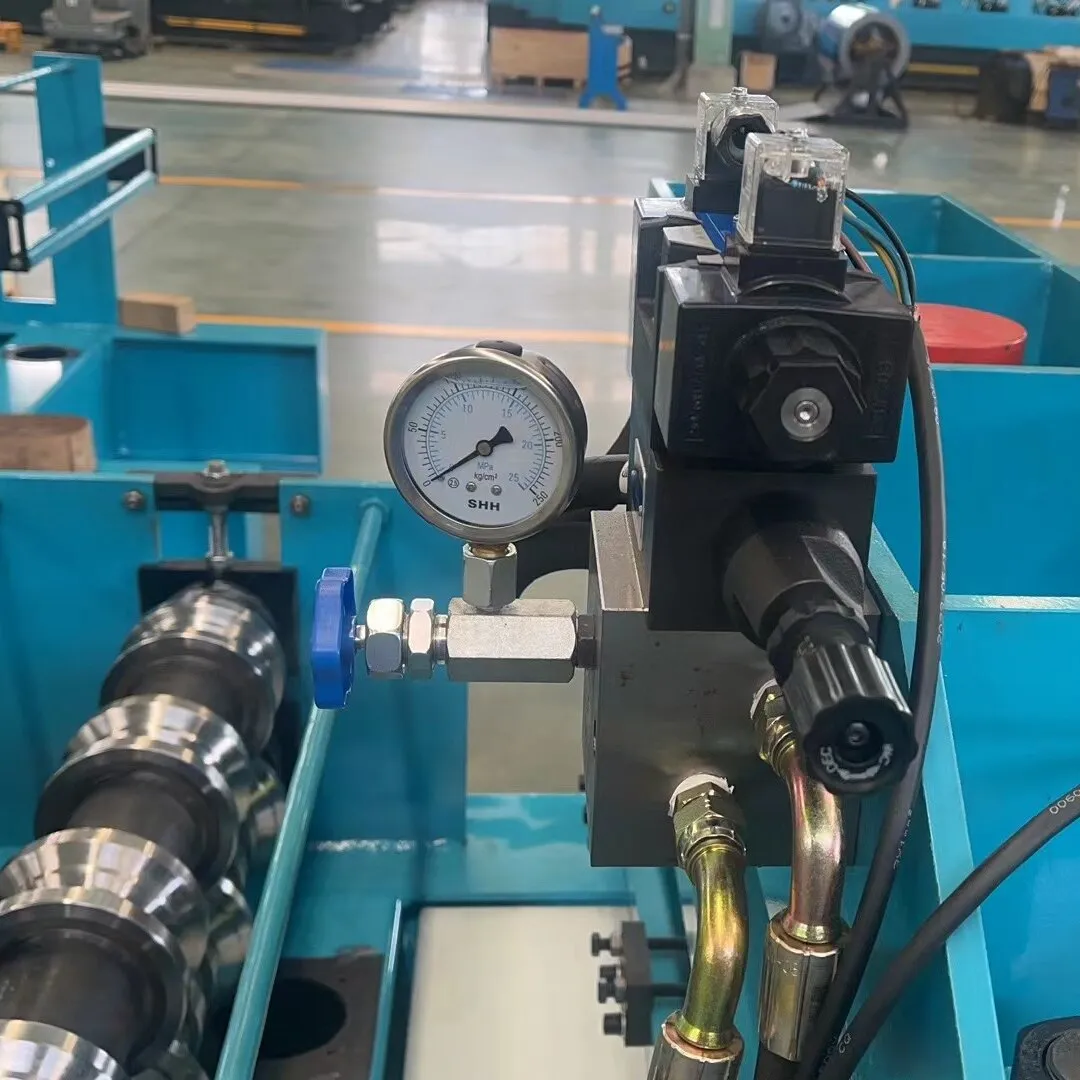

| Hydraulic station | x 1 set |

| PLC Control system | x 1 set |

| Run-out table (3M*2) | x 1 set |

Working Process

Technical Parameters

7.Brands for the electrical components

|

No. |

Name |

Brand |

Place |

|

1 |

Inverter(electrical control system) |

Yaskawa |

Japan |

|

2 |

LCD screen (electrical control system) |

Delta |

Taiwan |

|

3 |

PLC (electrical control system) |

Siemens |

Germany |

|

4 |

Encoder |

Omron |

Japan |

|

4 |

Reducer (forming machine) |

Huiyuan |

China |

|

5 |

Electrical low-voltage control components |

Schneider, Panasonic |

Germany,Japan |

|

6 |

Hydraulic components |

Wuxi Wansheng |

China |

|

7 |

Bearing |

Harbin |

8.Security Guarantee:

1) The design and manufacture of equipment comply with relevant national and industry safety standards;

2) Have a complete chain protection device and safety detection and protection facilities to avoid production, quality and safety accidents caused by misoperation;

3) All exposed transmission parts are equipped with protective covers and other protective devices;