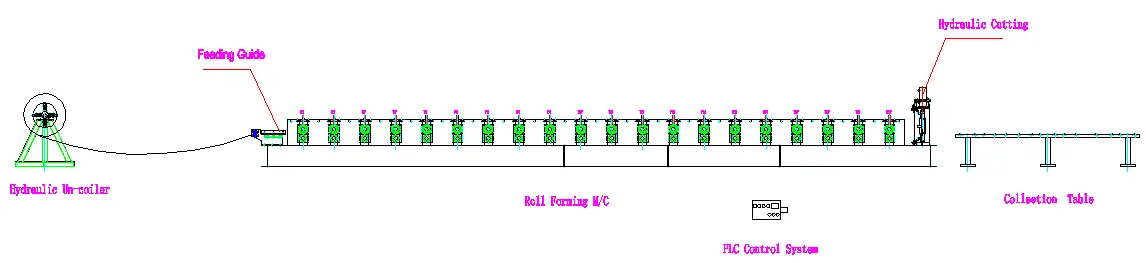

Drawings

Production process

Parameters And Specification

|

Manual Decoiler |

1: Max width of raw material :350mm 2: Capacity: 3000kgs 3: Inner diameter of coil: 450-600mm |

|

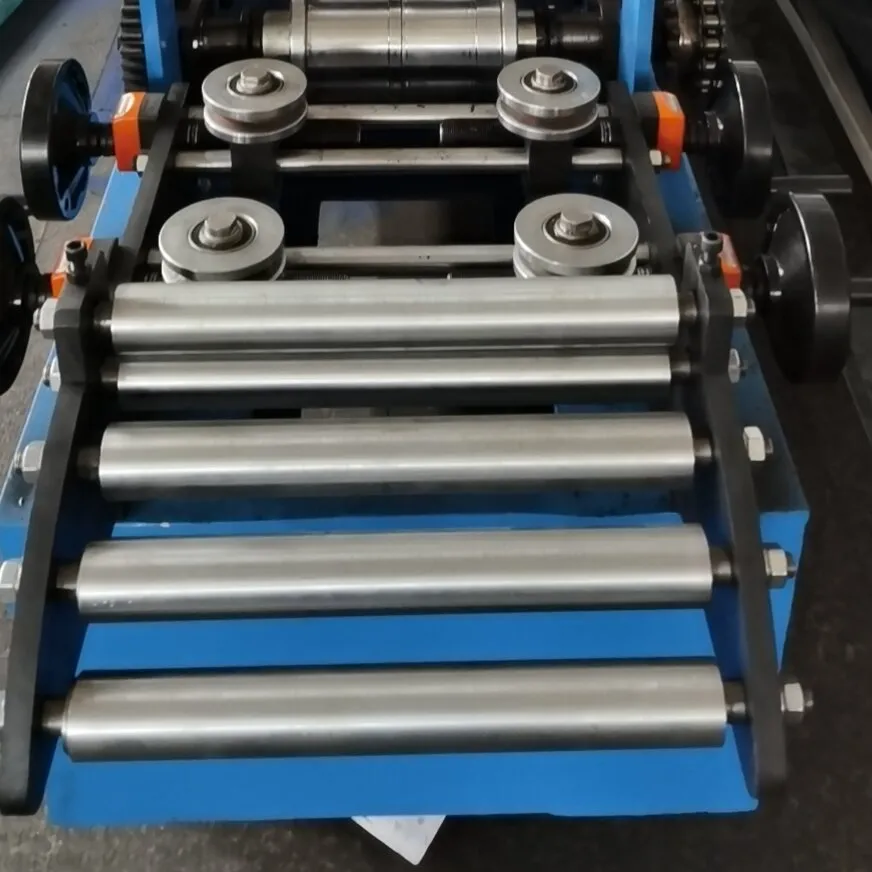

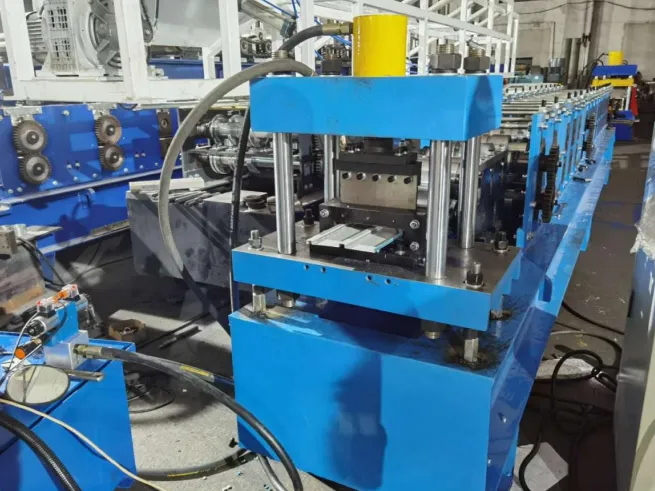

Roll forming machine |

1. Material thickness range:0.89/1.25mm 2. Main motor power: 4 kw 3. Hydraulic station: 3 kw 4. Speed: 15-20m/min 5. Quantity of rollers:14 rollers 6. Material of rollers: 45# with chromed 7. Shaft Material and diameter: ¢60 mm, material is 45# forge steel 8. Tolerance: 10m+-1.5mm 9. Way Of Drive: Chain 10. Control system: PLC 11. Material of cutter blade: Cr12 mould steel with quenched treatment 58-62℃ 12. Voltage: 220V/ 3phase/ 60 Hz |

|

Cutting (hydraulic guide) |

1. Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start. 2. Material of blade: Cr12 mould steel with quenched treatment 58-62℃ 3. Length measuring: Automatic length measuring 4. Tolerance of length: 10+/- 1.5mm |

|

PLC control system

|

1. Voltage, Frequency, Phase: 220V, 60 Hz, 3Phase 2. Automatic length measurement: 3. Automatic quantity measurement 4. Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved 5. Length inaccuracy can be amended easily 6. Control panel: Button-type switch and touch screen 7. Unit of length: millimeter (switched on the control panel) |

|

Collection table |

effective length:6M (standard) |

|

Appliance brand |

1. Frequency converter: Yaskawa, Japan |