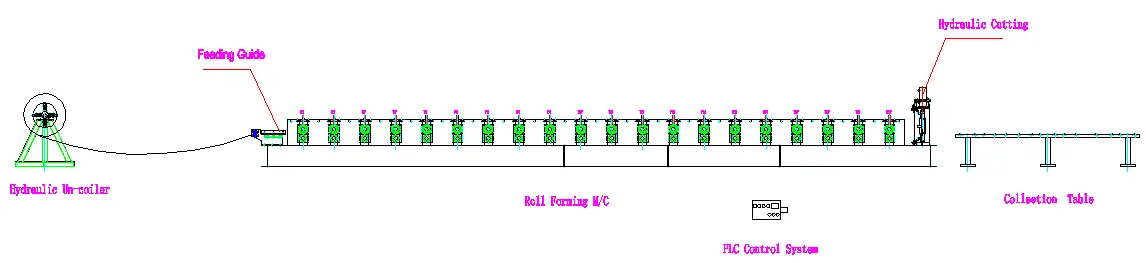

Chizmalar

Pishlab chiqarish jarayoni

Parametrlar va Saniqlashtirish

|

Qo'lda ochuvchi |

1: Xom ashyoning maksimal kengligi: 350 mm 2: Imkoniyat: 3000kgs 3: Bobinning ichki diametri: 450-600 mm |

|

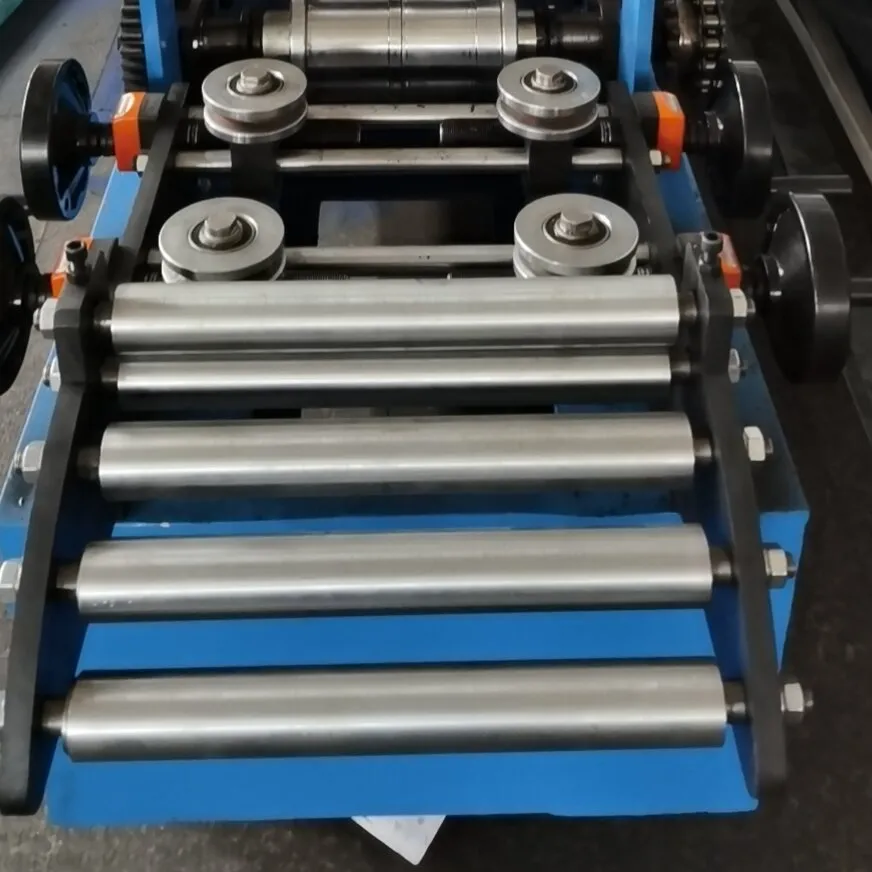

Rulo shakllantirish mashinasi |

1. Materialning qalinligi diapazoni: 0,89 / 1,25 mm 2. Asosiy dvigatel quvvati: 4 kVt 3. Gidrotexnika stansiyasi: 3 kVt 4. Speed: 15-20m/min 5. Roliklarning miqdori: 14 rolik 6. Roliklarning materiali: xromlangan 45 # 7. Milning materiali va diametri: ¢60 mm, material 45 # po'latdir 8. Tolerance: 10m+-1.5mm 9. Haydash usuli: zanjir 10. Boshqaruv tizimi: PLC 11. Material of cutter blade: Cr12 mould steel with quenched treatment 58-62℃ 12. Voltage: 220V/ 3 fazali/ 60 Hz |

|

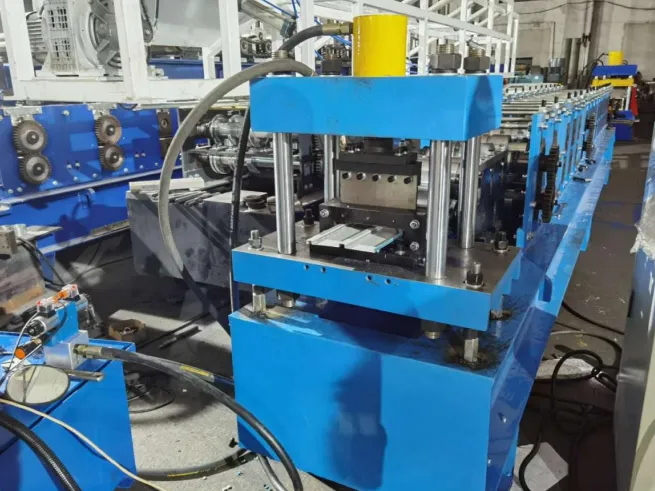

Kesish (gidravlik qo'llanma) |

1. Kesish harakati: Asosiy mashina avtomatik ravishda to'xtaydi va keyin kesishadi. Kesishdan so'ng asosiy mashina avtomatik ravishda ishga tushadi. 2. Material of blade: Cr12 mould steel with quenched treatment 58-62℃ 3. Length measuring: Automatic length measuring 4. Tolerance of length: 10+/- 1.5mm |

|

PLC boshqaruv tizimi

|

1. Voltage, Frequency, Phase: 220V, 60 Hz, 3Phase 2. Automatic length measurement: 3. Automatic quantity measurement 4. Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved 5. Length inaccuracy can be amended easily 6. Control panel: Button-type switch and touch screen 7. Unit of length: millimeter (switched on the control panel) |

|

Yig'ish jadvali |

samarali uzunlik: 6M (standart) |

|

Qurilma brendi |

1. Frequency converter: Yaskawa, Japan |