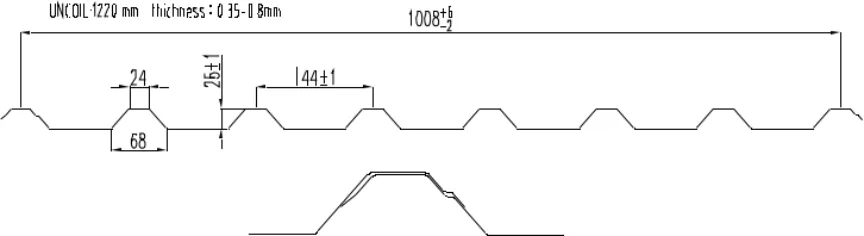

Vites qutisi bilan tom qoplamasi rulosini shakllantirish mashinasi

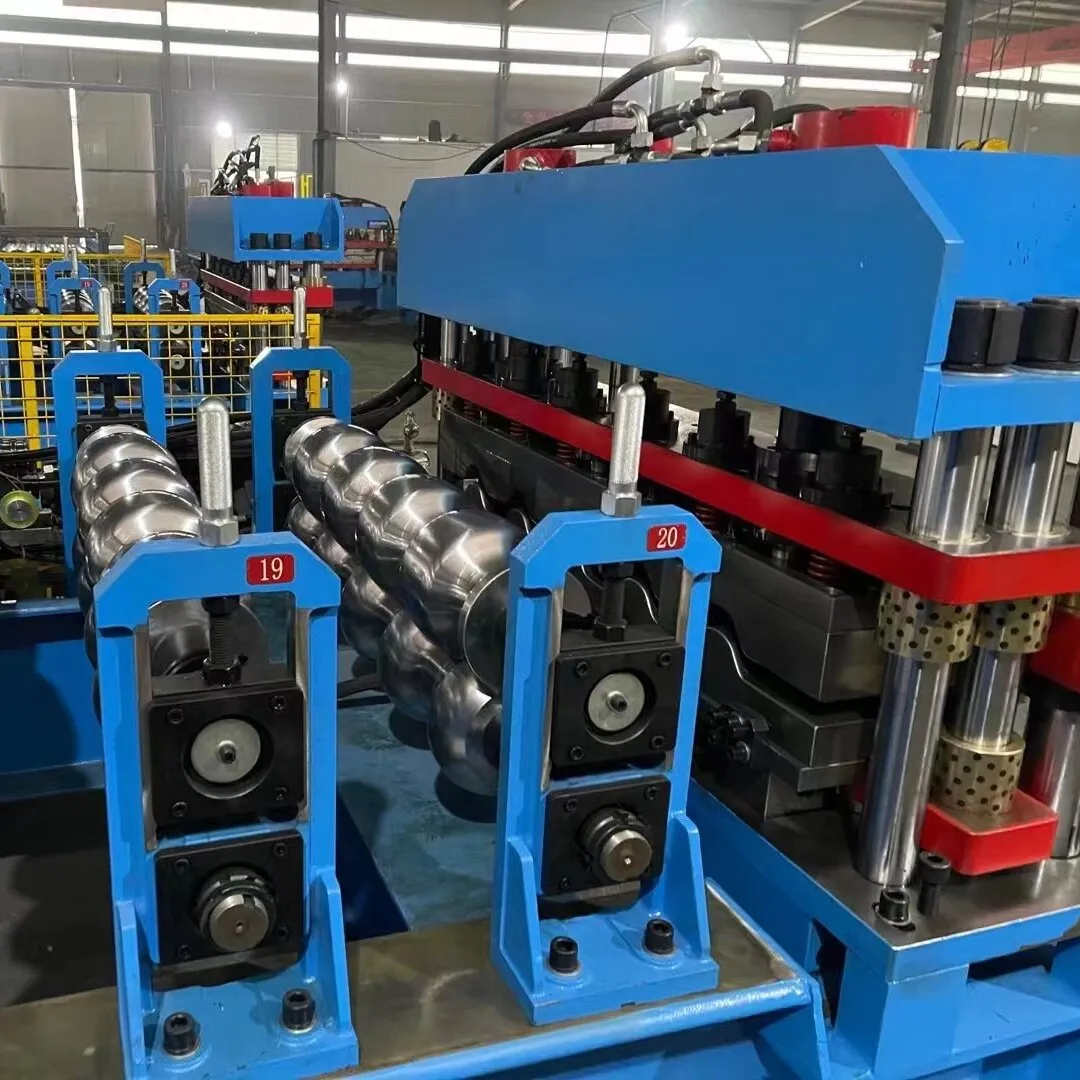

Vites qutisi bo'lgan tom qoplamasi rulosini shakllantirish mashinasi metall tom yopish plitalarini ishlab chiqarishda ishlatiladigan maxsus jihozdir. Vites qutisi ajralmas komponent bo'lib, u mashinaning tezligi va momentini boshqarishga yordam beradi, metall plitalar roliklardan o'tayotganda aniq shakllantirilishi va shakllanishini ta'minlaydi.

Dxom

Wishlash jarayoni

Komponent

| Manuel De-coiler | x1 to'plami |

| Asosiy rulonni shakllantirish mashinasi | x1 to'plami |

| Gidravlik kesish tizimi | x1 to'plami |

| Gidravlika stantsiyasi | x1 to'plami |

| PLC boshqaruv tizimi | x1 to'plami |

| Yig'ish jadvali | x1 to'plami |

Texnik parametrlar

Tishli qutining rulonni shakllantirish mashinasiga qo'shilishi bir qator afzalliklarni beradi:

1.Enhanced Torque: Gear boxes increase the torque output, allowing the machine to handle thicker or harder materials without compromising performance.

2.Speed Control: They provide better control over the speed of the rollers, ensuring uniformity in the thickness and shape of the produced sheets.

3.Durability: Gear boxes are designed to withstand heavy loads, which can extend the lifespan of the machine and reduce maintenance costs.

Tishli qutilari bo'lgan tom qoplamali rulonni shakllantirish mashinalari turli xil tom yopish plitalari profillarini ishlab chiqarishi mumkin, jumladan:

1.Corrugated Sheets: Commonly used in agricultural and industrial buildings.

2.Tile Profiles: Designed to mimic traditional tile roofing for aesthetic purposes.

3.Flat Sheets: Used for various applications, including siding and interior panels.

Ushbu mashinalarning ko'p qirraliligi ishlab chiqaruvchilarga bozorning turli ehtiyojlari va afzalliklarini qondirishga imkon beradi.

Roof sheet roll forming machines are typically designed to work with a variety of materials, including galvanized steel, aluminum, and other metal alloys. The specific material compatibility may vary depending on the machine’s design and specifications, so it’s important to consult the manufacturer for details.

Regular maintenance is essential to ensure the longevity and optimal performance of a roof sheet roll forming machine. This includes routine inspections of the gear box for wear and tear, lubrication of moving parts, checking for alignment issues, and ensuring that all electrical components are functioning properly. Following the manufacturer’s maintenance guidelines will help prevent breakdowns and extend the machine’s lifespan.