- albanialainen

- arabia

- bulgarialainen

- tanskalainen

- hollantilainen

- englanti

- suomalainen

- ranskalainen

- saksaksi

- kreikkalainen

- Unkari

- italialainen

- kazakki

- korealainen

- Kirgisia

- latina

- makedonialainen

- malaiji

- persialainen

- Kiillottaa

- portugali

- romanialainen

- venäjäksi

- espanja

- ruotsinkielinen

- thaimaalainen

- turkkilainen

- Turkmenistan

- uzbekki

- vietnam

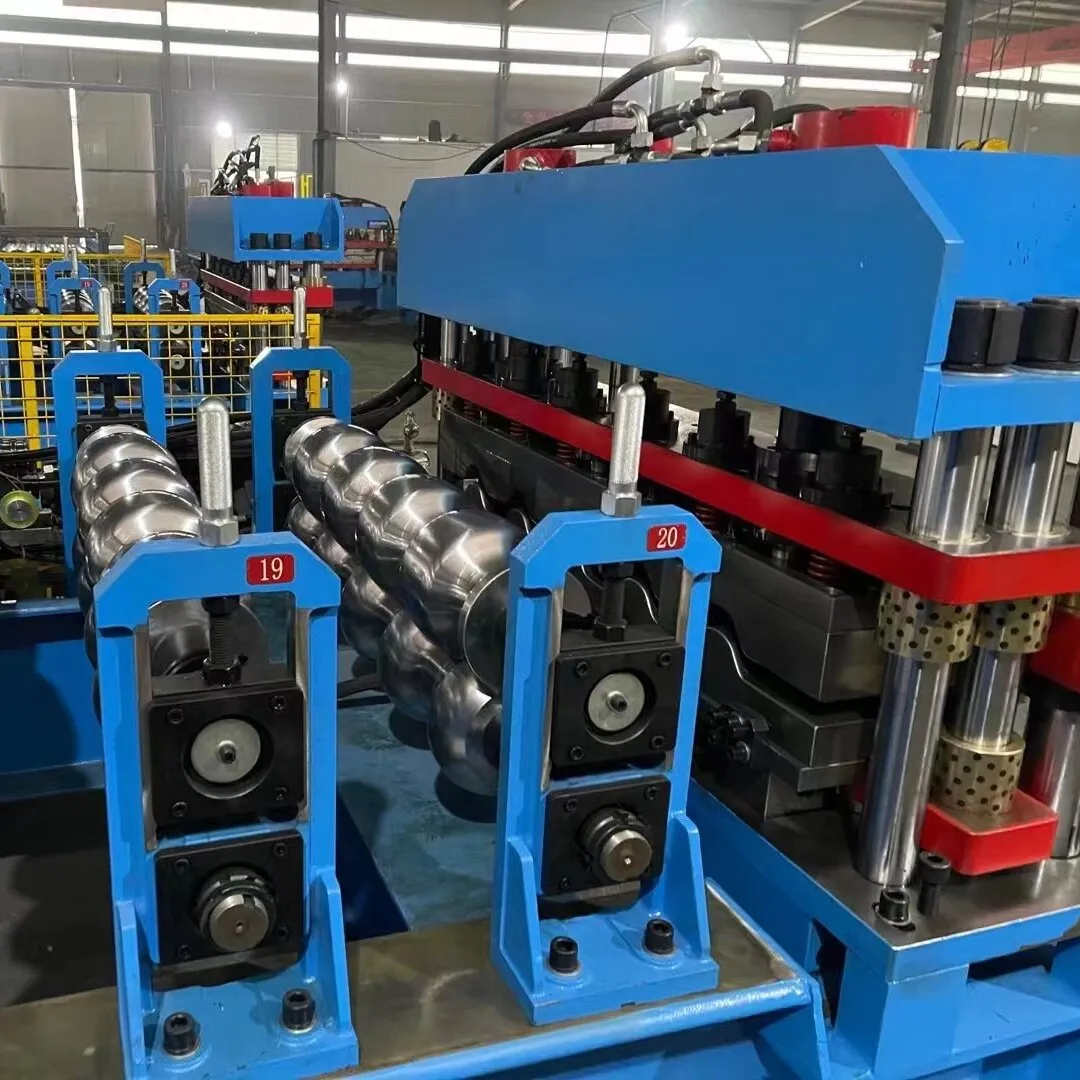

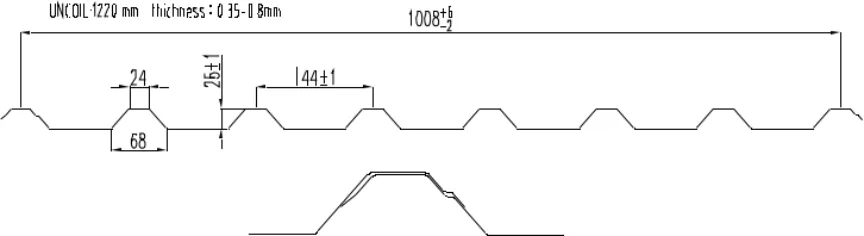

Vaihdelaatikolla varustettu kattopeltirullakone on erikoislaite, jota käytetään metallisten kattolevyjen valmistukseen. Vaihteisto on kiinteä osa, joka auttaa hallitsemaan koneen nopeutta ja vääntömomenttia varmistaen metallilevyjen tarkan muotoilun ja muotoilun niiden kulkiessa telojen läpi.

Draakana

Working prosessi

Komponentti

| Manuel De-coiler | x1 setti |

| Päärullanmuovauskone | x1 setti |

| Hydraulinen leikkausjärjestelmä | x1 setti |

| Hydrauliasema | x1 setti |

| PLC-ohjausjärjestelmä | x1 setti |

| Keräyspöytä | x1 setti |

Tekniset parametrit

Vaihteiston sisällyttäminen rullamuovauskoneeseen tarjoaa useita etuja:

1.Enhanced Torque: Gear boxes increase the torque output, allowing the machine to handle thicker or harder materials without compromising performance.

2.Speed Control: They provide better control over the speed of the rollers, ensuring uniformity in the thickness and shape of the produced sheets.

3.Durability: Gear boxes are designed to withstand heavy loads, which can extend the lifespan of the machine and reduce maintenance costs.

Vaihdelaatikoilla varustetut kattolevyrullakoneet voivat valmistaa erilaisia kattolevyprofiileja, mukaan lukien:

1.Corrugated Sheets: Commonly used in agricultural and industrial buildings.

2.Tile Profiles: Designed to mimic traditional tile roofing for aesthetic purposes.

3.Flat Sheets: Used for various applications, including siding and interior panels.

Näiden koneiden monipuolisuuden ansiosta valmistajat voivat vastata erilaisiin markkinoiden tarpeisiin ja mieltymyksiin.

Roof sheet roll forming machines are typically designed to work with a variety of materials, including galvanized steel, aluminum, and other metal alloys. The specific material compatibility may vary depending on the machine’s design and specifications, so it’s important to consult the manufacturer for details.

Regular maintenance is essential to ensure the longevity and optimal performance of a roof sheet roll forming machine. This includes routine inspections of the gear box for wear and tear, lubrication of moving parts, checking for alignment issues, and ensuring that all electrical components are functioning properly. Following the manufacturer’s maintenance guidelines will help prevent breakdowns and extend the machine’s lifespan.