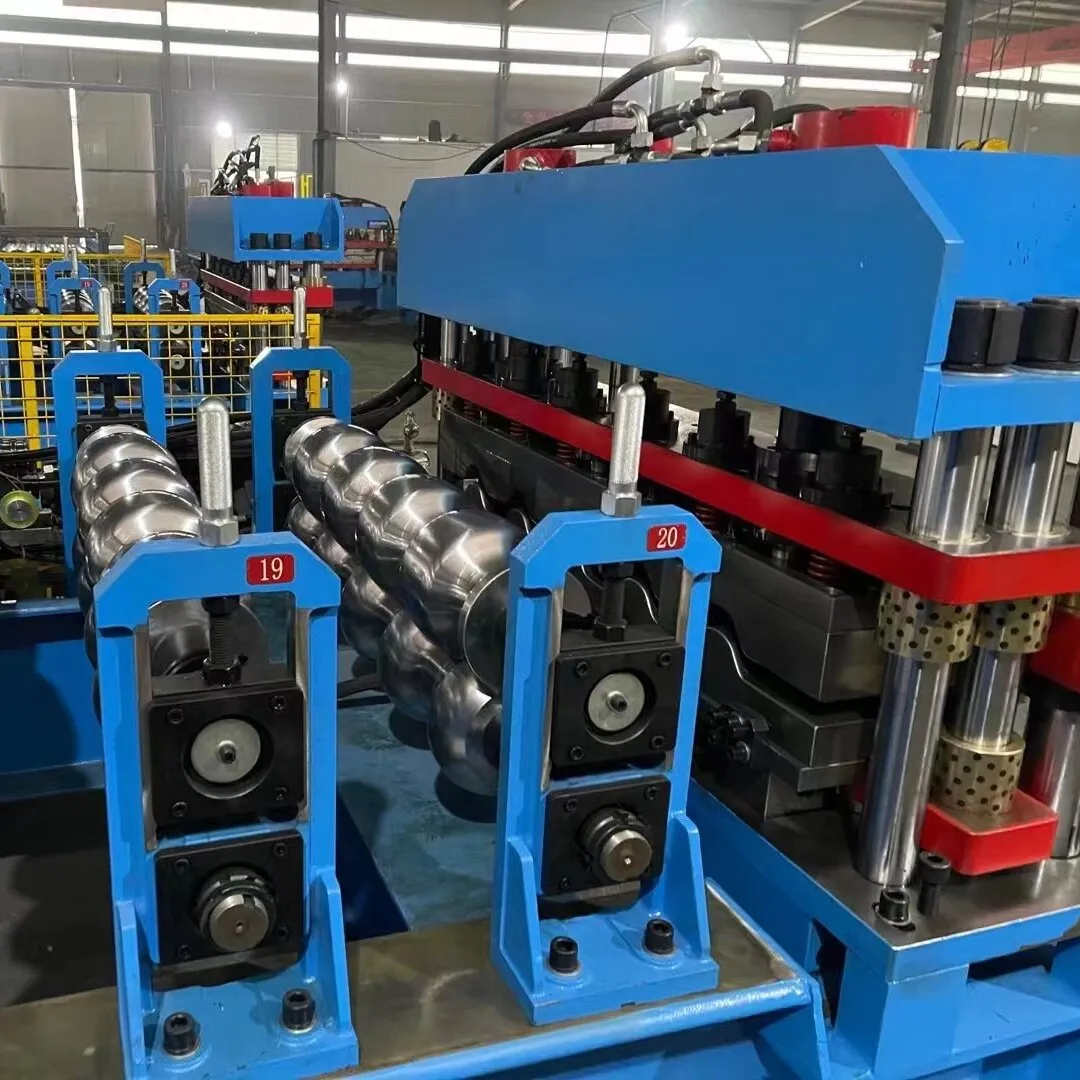

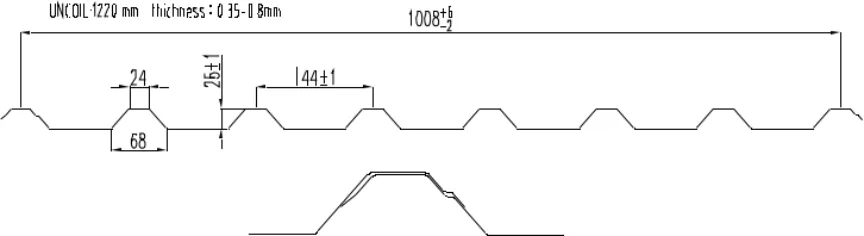

Dişli guty bilen üçek kagyz rulony emele getirýän maşyn, demir üçek örtüklerini öndürmekde ulanylýan ýöriteleşdirilen enjamdyr. Dişli guty, enjamyň tizligini we torkyny gözegçilikde saklamaga, rulonlardan geçip barýarka demir listleriň takyk emele gelmegini we emele gelmegini üpjün edýän aýrylmaz komponentdir.

Dçig mal

Working prosesi

Komponent

| Manuel De-coiler | x1 toplumy |

| Esasy rulon emele getiriji maşyn | x1 toplumy |

| Gidrawlik kesiş ulgamy | x1 toplumy |

| Gidrawlik stansiýasy | x1 toplumy |

| PLC dolandyryş ulgamy | x1 toplumy |

| Collectionygyndy tablisasy | x1 toplumy |

Tehniki parametrler

Dişli gutujygy rulon emele getirýän maşyna goşmak birnäçe artykmaçlygy hödürleýär:

1.Enhanced Torque: Gear boxes increase the torque output, allowing the machine to handle thicker or harder materials without compromising performance.

2.Speed Control: They provide better control over the speed of the rollers, ensuring uniformity in the thickness and shape of the produced sheets.

3.Durability: Gear boxes are designed to withstand heavy loads, which can extend the lifespan of the machine and reduce maintenance costs.

Dişli gutularly üçek list rulonlary emele getirýän maşynlar, üçek kagyz profilini öndürip biler, şol sanda:

1.Corrugated Sheets: Commonly used in agricultural and industrial buildings.

2.Tile Profiles: Designed to mimic traditional tile roofing for aesthetic purposes.

3.Flat Sheets: Used for various applications, including siding and interior panels.

Bu maşynlaryň köp taraplylygy öndürijilere dürli bazar zerurlyklaryny we isleglerini kanagatlandyrmaga mümkinçilik berýär.

Roof sheet roll forming machines are typically designed to work with a variety of materials, including galvanized steel, aluminum, and other metal alloys. The specific material compatibility may vary depending on the machine’s design and specifications, so it’s important to consult the manufacturer for details.

Regular maintenance is essential to ensure the longevity and optimal performance of a roof sheet roll forming machine. This includes routine inspections of the gear box for wear and tear, lubrication of moving parts, checking for alignment issues, and ensuring that all electrical components are functioning properly. Following the manufacturer’s maintenance guidelines will help prevent breakdowns and extend the machine’s lifespan.