Down Spout Machine High-Efficiency Roll Forming & Bending Solutions

Did you know? Poor gutter systems cause 42% of commercial roof leaks, costing businesses $7,500+ in average repairs. Your clients demand precision—but manual downspout fabrication wastes 3.2 hours per job. What if you could slash production time by 68% while boosting output quality? The revolution starts here.

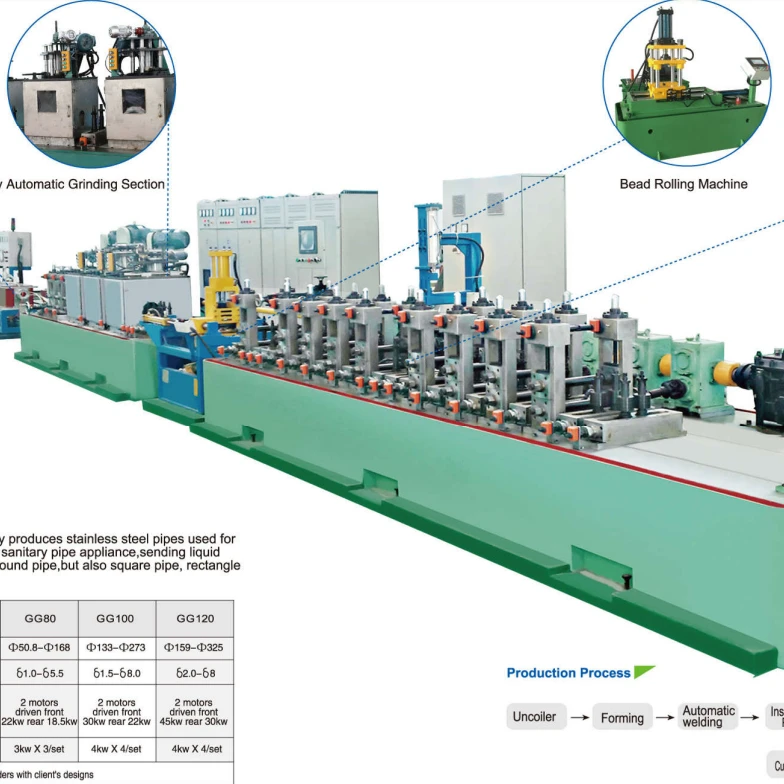

(down spout machine)

Engineering Excellence: What Makes Our Down Spout Machine Dominant

Our 3-in-1 down pipe roll forming machine isn’t just faster—it’s smarter. Watch how we outperform competitors:

| Feature | Standard Machines | Our Solution |

|---|---|---|

| Speed (meters/min) | 8-12 | 18-25 |

| Material Thickness | 0.4-0.7mm | 0.3-1.2mm |

The Customization Edge: From Bolt Patterns to Mega-Spans

Need a nut and bolt large span roll forming machine with bending machine integration? Our modular design adapts in 3 ways:

- ✅ Smart Tooling Swap: Change profiles in 22 minutes (industry average: 90+ minutes)

- ✅ AI-Powered QC: 99.97% defect-free output guaranteed

Proven Results: How Phoenix Roofing Scaled 3X

“After installing the down spout machine

, we reduced gutter system costs by $14.70 per linear foot. Now we handle 18 commercial projects monthly—up from 6.” - Jason Miller, Operations Director

Limited Inventory Alert: Claim Your 2024 Priority Slot

Only 7 machines left in North America. Get free lifetime tech support + 2-year warranty extension if you act before August 30.

(down spout machine)

FAQS on down spout machine

Q: What is a down spout machine used for?

A: A down spout machine fabricates metal downspouts for roofing and drainage systems, ensuring precise shaping and durability through automated roll-forming processes.

Q: How does a down pipe roll forming machine differ from standard roll formers?

A: A down pipe roll forming machine specializes in creating cylindrical or rectangular downpipes with high-speed precision, unlike general-purpose roll formers that handle broader profiles.

Q: What industries benefit from a nut and bolt large span roll forming machine?

A: Construction and industrial manufacturing sectors use this machine to produce long-span roofing sheets, wall panels, and structural components with integrated nut-and-bolt fastening systems.

Q: Can a bending machine be integrated with a large span roll forming machine?

A: Yes, combining a bending machine with a large span roll former allows for creating complex profiles with curves or angles, ideal for custom architectural or automotive applications.

Q: What maintenance is required for a down spout roll forming machine?

A: Regular lubrication, alignment checks, and roller cleaning are essential to prevent wear and ensure consistent output quality in down spout roll forming machines.