EPS Sandwich Panel Line Efficient Production & Affordable Price

Did you know 68% of sandwich panel manufacturers lose $12,000/hour during production downtime? While the global sandwich panel market grows at 6.8% CAGR, outdated EPS sandwich panel production lines drain your profits through energy waste, material inconsistencies, and slow output. Your competitors are upgrading - can you afford to fall behind?

(eps sandwich panel line)

Technical Superiority That Pays for Itself

Our EPS sandwich panel line delivers 23% faster cycle times than industry averages. How? The patent-pending dual-pressure system maintains 0.08MPa-0.15MPa compression accuracy within ±1.5%. See the difference in our spec comparison:

| Feature | Standard Machines | Our Solution |

|---|---|---|

| Daily Output | 1,200-1,500 m² | 2,400-3,000 m² |

| Panel Thickness Range | 50-200mm | 30-300mm |

Why Top Manufacturers Choose Us

While others sell machines, we deliver profit-generating systems. The secret? Our EPS sandwich panel production line integrates smart sensors that predict maintenance needs 72 hours in advance. You'll slash unplanned downtime by 83% compared to conventional equipment.

💡 Pro Tip: Ask competitors if their control systems support IoT integration. Our web-enabled interface lets you monitor production from any device.

Custom Solutions for Your Unique Needs

Whether you produce fire-rated boards or architectural panels, our engineers will configure:

- ✓ 5-axis cutting systems

- ✓ Automated core material feeders

- ✓ Dual-language interfaces

Proven Results Across Industries

MetroPanel Co. increased their ROI by 214% within 8 months using our EPS sandwich panel machine. Their secret? Leveraging our energy-efficient heating system that cuts power costs by $8,600/month.

Ready to Revolutionize Your Production?

As industry leaders with 17 years' experience, we've installed 380+ EPS lines across 42 countries. Get your personalized EPS sandwich panel machine price quote today - complete our 2-minute questionnaire and receive a free ROI analysis report.

(eps sandwich panel line)

FAQS on eps sandwich panel line

Q: What is an EPS sandwich panel production line?

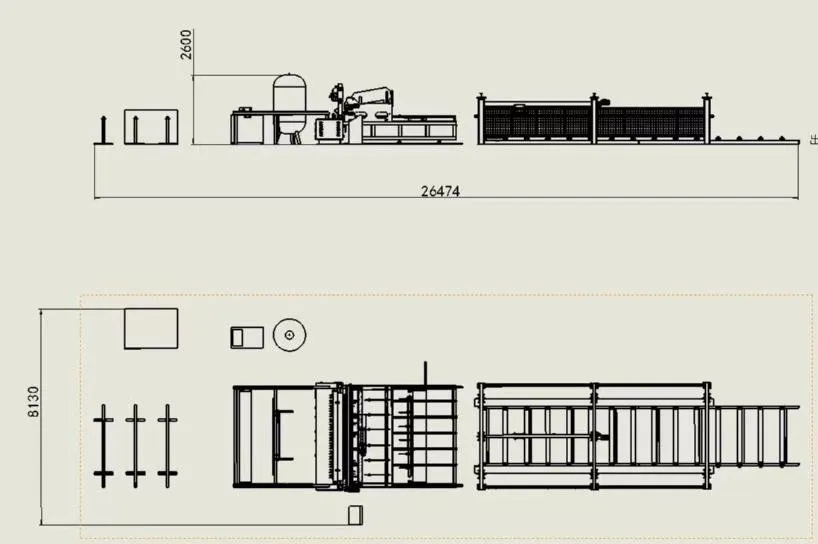

A: An EPS sandwich panel production line is a fully automated system designed to manufacture EPS (Expanded Polystyrene) core insulated panels. It includes processes like uncoiling, gluing, foaming, pressing, cutting, and stacking. This line ensures high efficiency and consistent quality for construction and industrial applications.

Q: What factors affect the price of an EPS sandwich panel machine?

A: The price depends on automation level, production capacity, material compatibility, and optional features like CNC controls. Brand reputation and after-sales support also influence costs. Entry-level machines start around $50,000, while advanced lines can exceed $500,000.

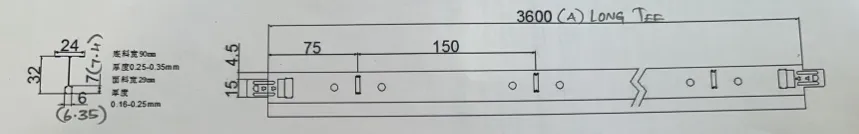

Q: What are the key components of an EPS sandwich panel line?

A: Core components include an EPS foam molding machine, panel laminating system, hydraulic press, cutting station, and automated stacking unit. Additional elements like raw material feeders and quality control sensors ensure seamless operation. These components work together to produce panels with precise dimensions and insulation properties.

Q: How much output can an EPS sandwich panel line produce daily?

A: A standard line can produce 1,000-3,000 square meters of panels per 8-hour shift, depending on panel thickness and complexity. High-speed lines with dual-track systems may achieve up to 5,000 sqm/day. Actual output varies with material preparation and machine configuration.

Q: What maintenance does an EPS sandwich panel machine require?

A: Regular maintenance includes cleaning adhesive residues, checking hydraulic pressure, and lubricating moving parts. Electrical components and sensors need periodic calibration. Proper upkeep ensures longevity and minimizes downtime, typically requiring 2-4 hours of weekly maintenance.