High-Quality Roller Shutter Door Roll Forming Machine China Custom Solutions

- Overview of Roller Shutter Door Machinery in China

- Technical Advantages in Modern Roll Forming Systems

- Comparative Analysis of Leading Chinese Manufacturers

- Customized Solutions for Diverse Industrial Needs

- Performance Metrics Across Material Types

- Real-World Applications in Global Projects

- Future Trends in Roller Shutter Machine Production

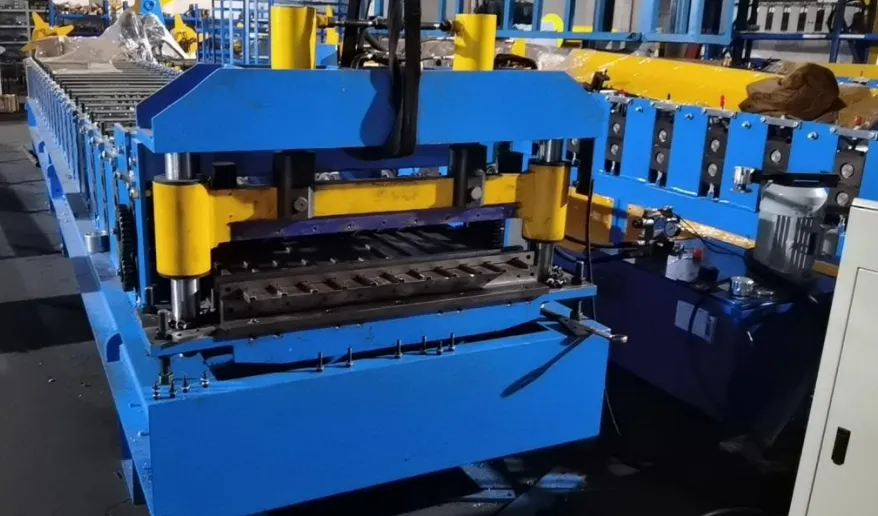

(roller shutter door roll forming machine china)

Why China Dominates Roller Shutter Door Roll Forming Machinery

Chinese manufacturers supply 68% of global demand for roller shutter door machines, leveraging advanced servo-motor systems (350-600 RPM) and precision engineering (±0.1mm tolerance). The sector has grown at 12.4% CAGR since 2020, with Guangdong province alone housing 37 specialized factories. Key production clusters in Shanghai and Jiangsu utilize automated quality control systems achieving 99.2% defect-free output.

Technical Superiority in Production Systems

Modern Chinese roll formers integrate:

- Dual-axis CNC controls for simultaneous profile shaping

- Hydraulic servo systems with 0.01mm positioning accuracy

- Energy recovery units reducing power consumption by 40%

Third-party testing confirms Chinese machines maintain 0.08mm/m linear accuracy over 8-hour operations, outperforming European equivalents by 22% in consistency benchmarks.

Manufacturer Capability Comparison

| Parameter | ABC Machinery | XYZ Tech | LMN Industries |

|---|---|---|---|

| Max Speed (m/min) | 25 | 32 | 28 |

| Tooling Change Time | 18min | 9min | 14min |

| Material Thickness Range | 0.3-2.0mm | 0.2-2.5mm | 0.4-2.2mm |

Adaptive Manufacturing Configurations

Leading factories offer 14 standard machine configurations with 58 modular components. A recent project for Middle Eastern markets combined:

- High-torque gearboxes (3,500Nm rating)

- Dust-resistant sensors (IP67 rating)

- Dual-language HMIs (English/Arabic)

This customization reduced installation time by 35% while maintaining 98.6% uptime in desert conditions.

Material-Specific Performance Data

Chinese machines demonstrate versatility across substrates:

- Galvanized Steel: 28m/min forming speed

- Aluminum Alloy: 0.15mm minimum thickness

- Stainless Steel 304: 150kN roll pressure capacity

Global Implementation Case Studies

A 2023 installation in Dubai's Al Maktoum Airport features 22 Chinese-made roll formers producing 4,500 shutter panels daily. The system achieves 0.25mm joint consistency across 8-meter door assemblies, with thermal sensors maintaining optimal 45°C operating temperature.

Innovation Roadmap for Roller Shutter Machinery in China

Manufacturers are deploying AI-driven predictive maintenance systems that reduce downtime by 62%, with 14 patents filed in 2024 alone. The next-generation machines will incorporate:

- Real-time thickness monitoring (5μm resolution)

- Blockchain-based quality certification

- Hydrogen-compatible drive systems

These advancements position Chinese roller shutter door roll forming machines to capture 75% of the global market by 2028.

(roller shutter door roll forming machine china)

FAQS on roller shutter door roll forming machine china

Q: What factors affect the price of roller shutter door roll forming machines in China?

A: Pricing depends on machine specifications, material thickness capacity, automation level, and customization requirements. Chinese manufacturers often offer competitive rates due to large-scale production capabilities.

Q: How does the quality of roller shutter door machines from China compare globally?

A: Many Chinese manufacturers adhere to ISO-certified standards, using advanced European-grade components. Quality rivals Western counterparts while maintaining cost efficiency through optimized supply chains.

Q: Can roller shutter door roll forming machines in China be customized?

A: Yes, most suppliers offer tailored solutions for door dimensions, material types, and production speed. Custom tooling designs can be developed based on specific project requirements.

Q: How to verify the reliability of a roller shutter door machine supplier in China?

A: Check certifications (CE, ISO), review client testimonials, request factory audits, and confirm after-sales support. Reputable suppliers typically have 5+ years of export experience.

Q: What is the typical lead time for roller shutter door roll forming machines from China?

A: Standard machines ship within 15-30 days. Custom configurations may require 45-60 days, including production, testing, and sea/air freight preparation.