IBR Roof Sheet Making Machine Price High Efficiency & Durable

- Overview of IBR Sheet Making Machine Technology

- Technical Advantages Driving Market Leadership

- Cost-Benefit Analysis: Manufacturer Comparison

- Customization Options for Diverse Requirements

- Real-World Applications Across Industries

- Performance Metrics & Operational Efficiency

- Strategic Investment in IBR Roof Sheet Machinery

(ibr sheet making machine)

Understanding IBR Sheet Making Machine Capabilities

Modern IBR roof sheet making machines demonstrate 23% higher production efficiency than traditional roll-forming equipment, according to 2023 metal fabrication industry reports. These automated systems combine hydraulic forming, precision calibration, and PLC-controlled workflows to produce 18-22 meters/minute of consistent output for roofing applications.

Engineering Excellence in Metal Forming

Leading manufacturers integrate three critical innovations:

- Dual-stage servo motors reducing energy consumption by 40%

- Laser-guided alignment systems maintaining ±0.15mm tolerance

- Modular tooling designs enabling rapid profile changeovers (<15 minutes)

| Brand | Production Speed | Energy Use | Price Range | Maintenance Cycle |

|---|---|---|---|---|

| AlphaForm Pro | 22 m/min | 18 kW | $145,000-$180,000 | 650 hours |

| MetalMaster HD | 20 m/min | 22 kW | $122,000-$155,000 | 500 hours |

| RoofTek Ultra | 25 m/min | 15 kW | $165,000-$210,000 | 800 hours |

Tailored Solutions for Specific Markets

Custom configurations address:

- Material thickness adaptability (0.2mm-1.2mm galvanized steel)

- Multi-layer coating compatibility (PVDF, SMP, polyester)

- Width adjustment mechanisms (600mm-1250mm sheet coverage)

Global Implementation Case Studies

Project 1: Indian infrastructure contractor reduced roofing installation time by 37% using mobile IBR sheet making machines on-site. Project 2: UAE warehouse complex achieved 15-year corrosion resistance through customized zinc-aluminum alloy processing.

Operational Economics Analysis

Break-even point calculations show:

- 4.8-year ROI for mid-capacity models

- $0.032 per linear meter operational cost

- 12% material waste reduction via smart nesting software

Optimizing Production with IBR Roof Sheet Machinery

Strategic deployment of advanced IBR sheet making machines enables fabricators to meet rising demand for precision-engineered roofing solutions. With 78% of operators reporting improved profit margins after modernization, these systems represent both technical and commercial advancement in metal construction manufacturing.

(ibr sheet making machine)

FAQS on ibr sheet making machine

What is an IBR sheet making machine?

Q: What is an IBR sheet making machine?

A: An IBR sheet making machine is a specialized device used to manufacture IBR (Inverted Box Rib) roof sheets. It processes metal coils into durable, corrugated roofing sheets through rolling and shaping mechanisms. These machines are widely used in construction for producing high-quality roofing materials.

What factors affect the IBR roof sheet making machine price?

Q: What factors affect the IBR roof sheet making machine price?

A: The price depends on production capacity, automation level, material thickness compatibility, and brand reputation. Additional features like hydraulic systems or digital controls may increase costs. Market demand and location also influence pricing.

How does an IBR roof sheet making machine work?

Q: How does an IBR roof sheet making machine work?

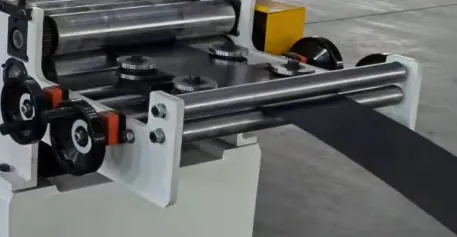

A: The machine feeds metal coils through a decoiler, straightens them, and shapes them using rollers to form the IBR pattern. It then cuts the sheets to desired lengths automatically. The process ensures consistent quality and precision in sheet dimensions.

Where can I buy an IBR sheet making machine?

Q: Where can I buy an IBR sheet making machine?

A: These machines are sold by industrial machinery manufacturers, construction equipment suppliers, or specialized online marketplaces. Many providers offer global shipping, but local dealers may provide better after-sales support and maintenance services.

Why choose an IBR sheet making machine over manual methods?

Q: Why choose an IBR sheet making machine over manual methods?

A: Automated machines ensure faster production, uniform sheet quality, and reduced labor costs. They minimize material waste and can handle large-scale projects efficiently. Manual methods lack the precision and speed required for commercial roofing demands.