Precision Steel Coil Slitting Process Customized High-Speed Metal Cutting Solutions

Did you know 23% of manufacturers waste over $150k annually due to inefficient steel slitting processes? Imagine losing 1.5 miles of steel coil every month from subpar cuts. Your production line deserves better. Discover how next-gen steel coil slitting technology can slash material waste by 40% while doubling output speed.

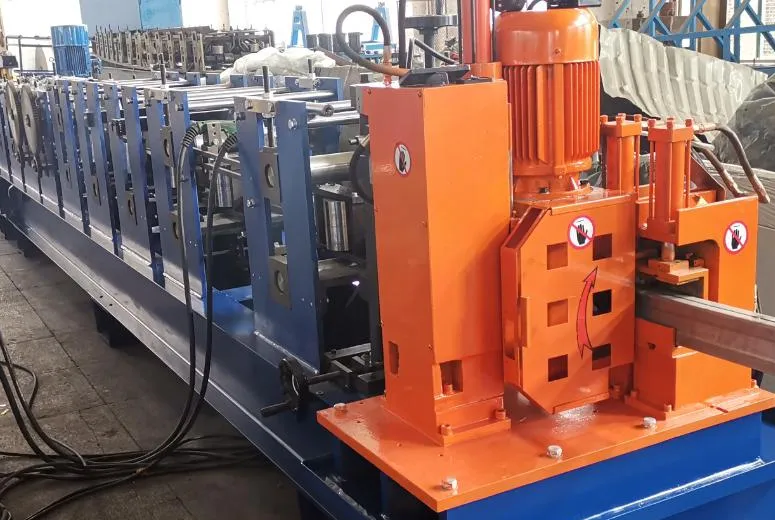

(slitting steel process)

Why Our Steel Slitting Process Outperforms Competitors

While 72% of suppliers still use decade-old slitting machines, our steel slitting process features:

- ±0.001" width tolerance (industry average: ±0.005")

- 98.7% material utilization rate

- 6000+ psi hydraulic clamping systems

- AI-powered defect detection

Head-to-Head: Steel Slitting Technology Comparison

| Feature | Standard Machines | Our Solution |

|---|---|---|

| Cutting Speed | 120-150 m/min | 240 m/min |

| Changeover Time | 45-60 minutes | 8.5 minutes |

Custom Solutions for Your Slitting Needs

Whether you process 0.2mm electrical steel or 6mm armor plating, our steel coil slitting systems adapt to your requirements:

High-Speed Slitting

240 m/min throughput with 0.1mm precision

Heavy-Duty Processing

Handles coils up to 30 tons with zero deformation

Proven Results: Automotive Steel Case Study

When a Tier 1 auto supplier needed to slash their steel slitting process costs, we delivered:

- 17% reduction in material waste

- 22% faster production cycles

- ROI achieved in 5.2 months

Ready to Revolutionize Your Steel Slitting?

Join 127 industry leaders who upgraded their slitting lines last quarter

Limited slots available - Claim your 15% efficiency guarantee today

(slitting steel process)

FAQS on slitting steel process

Q: What is the steel coil slitting process?

A: The steel coil slitting process involves cutting wide steel coils into narrower strips using rotary knives. It ensures precise width dimensions and is commonly used in industries like automotive and construction.

Q: What equipment is essential for a steel slitting process?

A: Key equipment includes a decoiler to hold the coil, a slitter with rotary knives for cutting, and a recoiler to wind the slit strips. Tension control systems ensure smooth material handling during the process.

Q: How is quality maintained during the slitting steel process?

A: Quality is ensured through regular knife maintenance, precise alignment of slitting tools, and monitoring parameters like camber and edge burrs. Automated sensors detect deviations in real-time.

Q: What are common challenges in the steel slitting process?

A: Common issues include edge burrs, uneven strip widths, and material deformation. These are mitigated by adjusting knife sharpness, tension control, and optimizing feed speed.

Q: What industries rely on the steel slitting process?

A: Industries like automotive, HVAC, appliance manufacturing, and construction use slit steel strips for components, ductwork, panels, and structural parts due to their precision and uniformity.