- Tiếng Albania

- Tiếng Ả Rập

- Tiếng Bulgaria

- Tiếng Đan Mạch

- Tiếng Hà Lan

- Tiếng Anh

- Phần Lan

- Tiếng Pháp

- Tiếng Đức

- Tiếng Hy Lạp

- Tiếng Hungary

- Tiếng Ý

- tiếng kazakh

- Hàn Quốc

- Tiếng Kyrgyzstan

- Tiếng La-tinh

- Tiếng Macedonia

- Tiếng Mã Lai

- Tiếng Ba Tư

- Đánh bóng

- Tiếng Bồ Đào Nha

- Tiếng Rumani

- Tiếng Nga

- Tiếng Tây Ban Nha

- Tiếng Thụy Điển

- Thái Lan

- Thổ Nhĩ Kỳ

- Người Turkmen

- Tiếng Uzbek

- Tiếng Việt

Stainless Steel Tube Mill: A Game Changer for Pipe Manufacturing

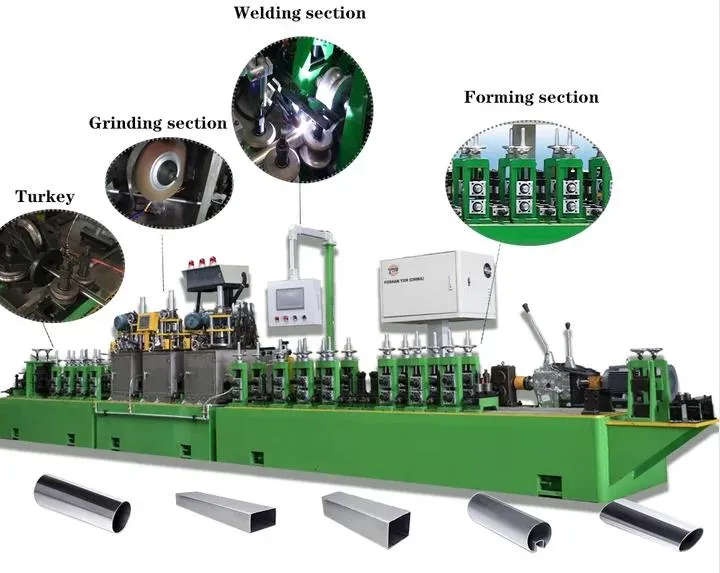

Các stainless steel tube mill machine is the backbone of modern pipe production, offering manufacturers a robust solution for high-quality stainless steel tubes. These machines are designed to transform raw stainless steel coils into finished tubes used across a wide range of industries, from construction and automotive to energy and food processing. The process is highly automated, ensuring precision and efficiency at every step.

The key processes involved in the operation of a stainless steel tube mill machine include slitting, forming, welding, sizing, and finishing. First, stainless steel coils are uncoiled and slit into narrower strips. These strips are then formed into tubular shapes using rollers or dies. After the tube is formed, the edges are welded together using advanced welding techniques such as TIG (Tungsten Inert Gas) or laser welding, ensuring a strong and seamless finish. The tube is then sized to the correct dimensions before undergoing surface treatments like polishing or passivation to improve both its appearance and corrosion resistance.

The precision of a stainless steel tube mill machine ensures that the final product meets strict industry standards for strength, durability, and consistency. By automating the manufacturing process, this equipment reduces production times, minimizes material waste, and lowers overall operational costs, making it a worthwhile investment for companies in the metalworking industry.

Carbon Steel Tube Mill: Durable and Reliable Solutions for Heavy-Duty Applications

A carbon steel tube mill is an essential piece of machinery for producing high-strength carbon steel tubes that are used in industries such as construction, automotive, and industrial manufacturing. Carbon steel is widely known for its durability and resistance to wear, making it an ideal choice for pipes and tubes that need to withstand heavy-duty applications.

Các carbon steel tube mill operates through a similar process as the stainless steel tube mill machine, but the material itself is different. Carbon steel tubes are made from carbon steel coils that are fed into the machine and processed through slitting, forming, welding, sizing, and finishing. The main difference is that the welding process used in carbon steel tube mills may include different techniques such as high-frequency welding, which ensures a strong bond between the steel edges.

These mills are built to handle the challenges of working with carbon steel, ensuring that the final products are robust and reliable. They are highly efficient, capable of producing large volumes of tubes in a short amount of time, without compromising on quality. The carbon steel tube mill is a critical machine for manufacturers who need to produce pipes and tubes for construction projects, automotive manufacturing, and other heavy-duty applications.

Stainless Steel Tube Mill Manufacturer in China: Leading the Way in Innovation

China has long been a leader in manufacturing stainless steel tube mill machines, offering cutting-edge technology and expertise to businesses worldwide. The stainless steel tube mill manufacturer in China provides a range of machines designed to meet the demands of modern tube manufacturing. These manufacturers combine years of experience with the latest innovations in automation, materials science, and engineering to deliver high-quality, reliable tube mills.

Các stainless steel tube mill manufacturer in China offers machines that are not only efficient and durable but also customizable to meet the specific needs of various industries. Whether you need a machine capable of producing small-diameter tubes for medical applications or large-diameter tubes for construction projects, Chinese manufacturers have the expertise to provide the right equipment for the job.

Additionally, Chinese manufacturers are known for their competitive pricing and excellent customer support. They provide ongoing training, installation assistance, and after-sales service to ensure that your stainless steel tube mill machine operates at peak performance for years. By investing in equipment from a reputable stainless steel tube mill manufacturer in China, businesses can boost their production capacity while keeping costs down.

SS Tube Mill Machine Price: Affordable Solutions for High-Volume Production

When it comes to purchasing SS tube mill machines, price is often one of the most important considerations for manufacturers. The SS tube mill machine price varies based on factors such as the machine's size, production capacity, and the specific features required. However, despite the initial investment, the SS tube mill machine offers significant long-term savings in terms of productivity and efficiency.

An SS tube mill machine is a one-time investment that pays off through its ability to produce high-quality stainless steel tubes at a rapid pace. The price of the machine is often offset by the cost savings it offers in terms of reduced labor costs, material wastage, and downtime. Moreover, the durability of these machines means that they can last for many years with minimal maintenance, making them a cost-effective choice for businesses in the tube manufacturing industry.

For companies looking to save on initial costs, there are also financing options available from manufacturers or third-party financial institutions. This allows businesses to spread the cost of the SS tube mill machine over time, ensuring that they can upgrade their equipment without putting a strain on their budgets.

Choosing the Right Tube Mill for Your Business: Factors to Consider

When choosing a stainless steel tube mill machine, several factors should be considered to ensure that the machine meets your specific production needs. These include the machine's production capacity, the types of tubes it can produce, its energy efficiency, and the level of automation it offers. A well-chosen machine can significantly improve your production efficiency, reduce costs, and enhance the quality of your products.

First, consider the stainless steel tube mill machine’s production capacity. Different machines are designed to produce different quantities of tubes per hour, so it’s important to select a machine that aligns with your production goals. If your business requires high-volume production, you’ll need a machine capable of handling large batches without compromising on quality.

Next, ensure that the machine can produce the types of tubes you need. For example, if you need small-diameter stainless steel tubes for precision applications, you’ll need a machine capable of producing these specific sizes. Some stainless steel tube mill machines offer customizable features that allow manufacturers to produce a wide variety of tube sizes and thicknesses, making them highly versatile for different industries.

Another consideration is the machine's energy efficiency. Modern tube mills are designed to consume less power while maintaining high performance. Choosing an energy-efficient machine can help you reduce operational costs in the long run.

SS Tube Mill Machine Price FAQs

What is a stainless steel tube mill machine?

A stainless steel tube mill machine is used to convert stainless steel coils into finished tubes through a process of slitting, forming, welding, sizing, and finishing. These machines are essential for producing stainless steel pipes used in various industries.

How does a carbon steel tube mill differ from a stainless steel tube mill machine?

While both machines use similar processes, a carbon steel tube mill is designed specifically for processing carbon steel coils, whereas a stainless steel tube mill machine is tailored for stainless steel. The welding processes and materials handled by each machine vary due to the differences in the base metals.

Why should I choose a stainless steel tube mill manufacturer in China?

China is known for its advanced manufacturing capabilities and competitive pricing. A stainless steel tube mill manufacturer in China offers high-quality machines that are reliable, customizable, and cost-effective, backed by strong customer support.

What factors influence SS tube mill machine price?

Các SS tube mill machine price is influenced by factors such as production capacity, size, features, and the complexity of the machine. The price can also vary depending on whether the machine includes advanced automation features or custom specifications.

How can I ensure the best performance from my stainless steel tube mill machine?

To ensure optimal performance, choose a high-quality machine that meets your production needs, perform regular maintenance, and invest in staff training to operate the machine efficiently. Regular monitoring and upgrades can help extend the lifespan of your stainless steel tube mill machine.

In conclusion, investing in a stainless steel tube mill machine, carbon steel tube mill, or SS tube mill machine is a smart decision for businesses looking to optimize their pipe production process. Whether you are looking to produce high-quality stainless steel tubes or carbon steel tubes, these machines provide the precision, efficiency, and reliability needed to stay competitive in the market. For more information and to explore the best options available for your business, visit our website and take the next step toward enhancing your production capabilities.