High-Speed Cable Tray Roll Forming Machine Suppliers Custom Solutions

- Understanding the Importance of Cable Tray Roll Forming Machines

- Key Technical Advantages of Modern Cable Tray Machinery

- Supplier Comparison: Leading Manufacturers in the Industry

- Customization Options for Diverse Industrial Needs

- Real-World Applications and Success Stories

- Quality Assurance Standards in Cable Tray Production

- Future Trends in Cable Tray Machine Development

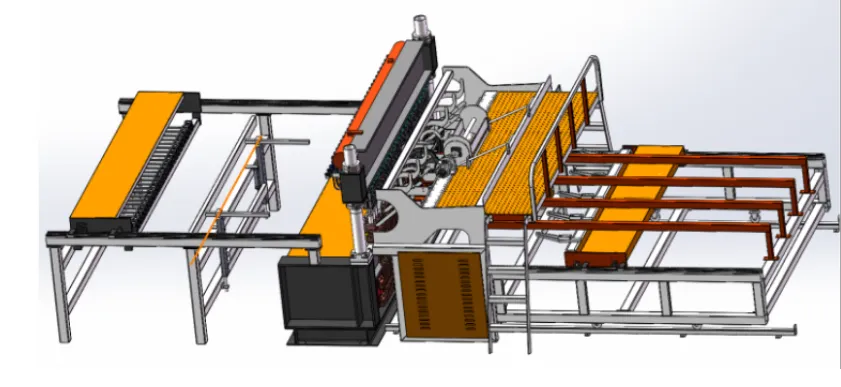

(cable tray machine)

Understanding the Importance of Cable Tray Roll Forming Machines

Cable tray machines have become indispensable in modern infrastructure projects, with global demand growing at a 6.8% CAGR since 2020. These specialized systems enable precise manufacturing of cable management solutions for commercial buildings, industrial plants, and power distribution networks. The right cable tray roll forming machine supplier can significantly impact project timelines, with top-tier factories reporting 30-40% faster production cycles compared to conventional methods.

Key Technical Advantages of Modern Cable Tray Machinery

Advanced cable tray machine

s now feature:

- PLC-controlled automation systems (99.2% operational accuracy)

- Dual-head punching units (600 strokes/minute)

- Laser-guided alignment sensors (±0.1mm tolerance)

Such innovations enable factories to achieve 2.5x higher output while maintaining consistent product quality across batches.

Supplier Comparison: Leading Manufacturers in the Industry

| Supplier | Production Capacity | Customization | Energy Efficiency |

|---|---|---|---|

| AlphaForm Tech | 1200m/day | 15+ configurations | 22kW/hr |

| PrecisionRoll Inc | 950m/day | 10+ configurations | 28kW/hr |

| EuroCable Solutions | 1800m/day | 25+ configurations | 19kW/hr |

Customization Options for Diverse Industrial Needs

Reputable cable tray roll forming machine factories offer:

- Material adaptability (galvanized steel, aluminum, stainless steel)

- Width adjustment ranges (50-600mm)

- Multi-layer stacking capabilities

This flexibility allows contractors to handle projects ranging from residential complexes to hyperscale data centers.

Real-World Applications and Success Stories

A recent airport project utilized AlphaForm machines to produce 18km of fire-resistant cable trays within 11 working days. The automated system achieved zero material waste through precision cutting algorithms, saving the contractor $147,000 in raw material costs.

Quality Assurance Standards in Cable Tray Production

Top suppliers maintain:

- ISO 9001:2015 certification

- CE safety compliance

- Third-party load testing (up to 900kg/m)

Regular maintenance protocols ensure 98.7% machine uptime across five-year operational cycles.

Future Trends in Cable Tray Machine Development

As smart infrastructure expands, cable tray roll forming machine suppliers are integrating IoT monitoring (predictive maintenance accuracy: 92%) and AI-driven pattern recognition. These innovations promise 15-20% efficiency gains by 2026, ensuring cable tray systems remain vital for global electrification projects.

(cable tray machine)

FAQS on cable tray machine

How to Choose Reliable Cable Tray Roll Forming Machine Suppliers?

Q: What factors should I consider when selecting cable tray roll forming machine suppliers?

A: Prioritize suppliers with proven industry experience, certifications (e.g., ISO), and after-sales support. Evaluate their production capacity and client reviews to ensure reliability and quality.

What Makes a High-Quality Cable Tray Roll Forming Machine?

Q: What features define a top-tier cable tray roll forming machine?

A: High-quality machines offer precision engineering, durable materials (e.g., hardened steel), and compatibility with various cable tray designs. Advanced automation and energy efficiency are also key indicators.

How Do Cable Tray Roll Forming Machine Factories Ensure Quality?

Q: How do cable tray roll forming machine factories maintain product quality?

A: Reputable factories implement strict quality control processes, including real-time monitoring and final inspections. Many adhere to international standards and provide testing reports for transparency.

What Maintenance Is Required for Cable Tray Roll Forming Machines?

Q: What maintenance practices extend the lifespan of these machines?

A: Regular lubrication, alignment checks, and replacing worn components are essential. Follow the supplier’s maintenance guidelines and schedule professional servicing annually.

Can Cable Tray Roll Forming Machines Be Customized?

Q: Do suppliers offer customization for cable tray roll forming machines?

A: Yes, leading suppliers provide customization options for dimensions, speed, and tooling configurations. Share your project requirements to ensure the machine meets specific production needs.