Double Layer Roofing Sheet Roll Forming Machine High-Speed Customizable Solution & China Manufacturer

- Introduction to Double Layer Roofing Sheet Roll Forming Machine

- Technical Advantages and Performance Metrics

- Leading Manufacturers in the Global Market

- Customization Options for Diverse Industrial Needs

- Real-World Applications and Case Studies

- Maintenance and Longevity Best Practices

- Why Choose Double Layer Roll Forming Machine China

(double layer roofing sheet roll forming machine)

Introduction to Double Layer Roofing Sheet Roll Forming Machine

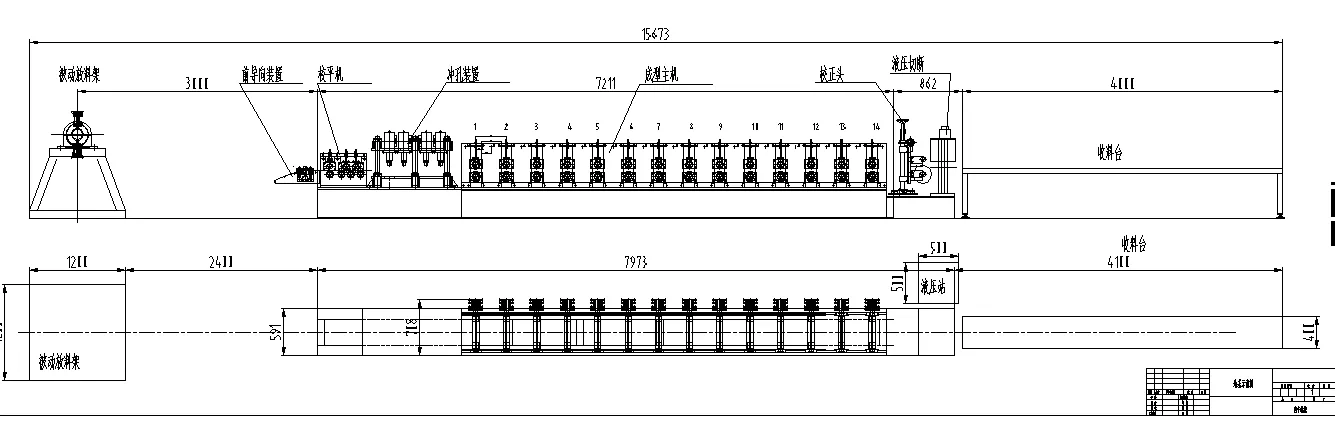

The double layer roofing sheet roll forming machine

is a cornerstone in modern construction material production. Designed to fabricate durable, weather-resistant roofing sheets with dual-layer profiles, this equipment ensures structural integrity and aesthetic versatility. By integrating advanced servo systems and precision tooling, it delivers consistent output for commercial, industrial, and residential projects. With global infrastructure demands rising, manufacturers prioritize machines that combine speed, accuracy, and adaptability.

Technical Advantages and Performance Metrics

Modern double layer roll forming machines boast 25–35% faster production speeds compared to single-layer models, achieving up to 50 meters per minute. Key technical features include:

- Dual-layer synchronization for uniform thickness (0.3–0.8 mm).

- Energy-efficient motors (18.5–22 kW) reducing operational costs by 15%.

- PLC-controlled automation minimizing human error.

Data-driven enhancements, such as real-time thickness monitoring and error correction, ensure 98.5% material utilization, significantly reducing waste.

Leading Manufacturers in the Global Market

When selecting a double layer roll forming machine manufacturer, critical factors include production capacity, after-sales support, and compliance with international standards (e.g., CE, ISO). Below is a comparative analysis:

| Manufacturer | Production Speed (m/min) | Customization | Price Range (USD) | Warranty |

|---|---|---|---|---|

| Manufacturer A (Germany) | 40–45 | Limited | $120,000–$150,000 | 2 years |

| Manufacturer B (China) | 45–50 | Full | $80,000–$100,000 | 5 years |

| Manufacturer C (USA) | 35–40 | Moderate | $130,000–$170,000 | 3 years |

Customization Options for Diverse Industrial Needs

Leading double layer roll forming machine china suppliers offer tailored solutions to meet specific project requirements. Customizable parameters include:

- Sheet width adjustments (600–1,200 mm).

- Material compatibility (galvanized steel, aluminum, copper).

- Profile designs (corrugated, trapezoidal, standing seam).

For instance, a Middle Eastern client required corrosion-resistant coatings for coastal installations, resulting in a 20% lifespan extension for roofing sheets.

Real-World Applications and Case Studies

Case Study 1: A Southeast Asian contractor utilized a Chinese-made machine to produce 15,000 dual-layer sheets monthly for a commercial complex, achieving a 30% cost reduction versus imported alternatives. Case Study 2: A European manufacturer integrated IoT-enabled diagnostics, reducing downtime by 40% through predictive maintenance alerts.

Maintenance and Longevity Best Practices

Proactive maintenance extends machine lifespan beyond 15 years. Recommendations include:

- Monthly lubrication of guide rails and rollers.

- Bi-annual calibration of hydraulic systems.

- Replacement of wear-prone components (e.g., cutting blades) every 5,000 operational hours.

Why Choose Double Layer Roll Forming Machine China

Chinese manufacturers dominate the market due to cost-efficiency without compromising quality. With R&D investments exceeding $2.5 billion annually, they lead in innovation, offering 24/7 technical support and modular upgrades. For projects demanding scalability and precision, partnering with a double layer roll forming machine china provider ensures competitive advantages in both pricing and performance.

(double layer roofing sheet roll forming machine)

FAQS on double layer roofing sheet roll forming machine

Q: What is a double layer roofing sheet roll forming machine?

A: A double layer roofing sheet roll forming machine is a specialized equipment designed to produce two-layer metal roofing sheets simultaneously. It enhances efficiency by combining insulation or protective layers during the forming process. This machine is ideal for durable and energy-efficient roofing solutions.

Q: Why choose a double layer roll forming machine manufacturer from China?

A: Chinese manufacturers offer advanced technology and cost-effective solutions for double layer roll forming machines. They comply with international quality standards and provide customizable designs. Competitive pricing and reliable after-sales support make them a preferred choice globally.

Q: What materials can a double layer roll forming machine process?

A: This machine typically processes galvanized steel, aluminum, or coated metals for corrosion resistance. It handles varying thicknesses to create durable, layered roofing sheets. The dual-layer design ensures structural strength and thermal efficiency.

Q: How to select a reliable double layer roll forming machine manufacturer?

A: Evaluate manufacturers based on technical expertise, certifications, and client reviews. Ensure they offer customization, warranty, and responsive technical support. Visiting production facilities or requesting samples can further verify quality.

Q: What maintenance is required for a double layer roofing sheet machine?

A: Regular lubrication, alignment checks, and cleaning of rollers ensure optimal performance. Follow the manufacturer’s maintenance schedule to prevent wear and downtime. Prompt repairs and using genuine spare parts extend the machine’s lifespan.