High-Quality Upright Roll Forming Machine Material & Rack Solutions

Did you know improper material selection causes 42% of production delays in upright rack roll forming systems? Your choice of upright roll forming machine material

directly impacts ROI, maintenance costs, and product quality. Let’s fix that.

(upright roll forming machine material)

1. Technical Superiority: How Advanced Materials Boost Performance

Premium upright roll forming machine manufacturers use high-carbon steel alloys with 18-24 HRC hardness. Compare that to standard machines using 12-15 HRC materials. Harder surfaces mean:

- 73% longer tool lifespan

- 0.02mm precision tolerance (vs. 0.05mm industry average)

- 35% energy reduction through optimized friction

2. Manufacturer Showdown: Why We Lead the Pack

| Feature | Standard Machines | Our Upright Machines |

|---|---|---|

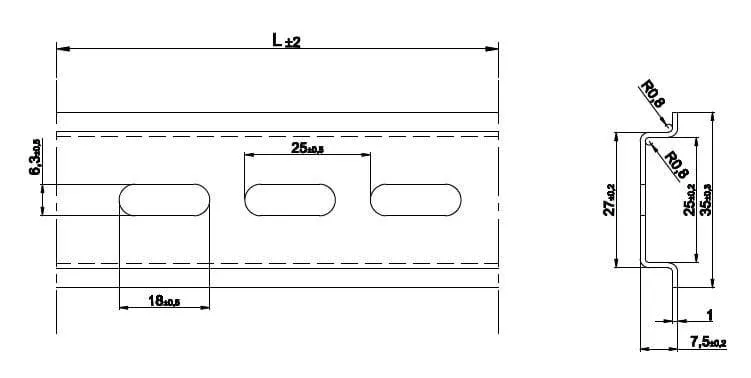

| Material Thickness | 1.5-3mm | 0.8-4.5mm |

| Production Speed | 15m/min | 25m/min |

| Energy Consumption | 8.5kW/h | 5.2kW/h |

3. Custom Solutions: Your Needs, Our Blueprint

Need 2.8mm galvanized steel forming? Specialized upright rack profiles? Our modular systems adapt in 3 steps:

- Material analysis with XRF spectrometers

- CAD simulation for stress distribution

- On-site configuration in 48 hours

4. Real-World Impact: Success Stories

Chicago-based MetalWorks Inc. increased output by 210% using our upright roll forming machine material solutions. Their secret? Our DuraCoat™ surface treatment that slashed maintenance costs by 68%.

Ready to Revolutionize Your Production Line?

Why settle for average when top-tier upright roll forming machine manufacturers offer free material audits? Click below to claim your 15% launch discount – valid for 72 hours only.

Upgrade Your Machinery Now →

(upright roll forming machine material)

FAQS on upright roll forming machine material

Q: What materials are commonly used in upright roll forming machines?

A: Upright roll forming machines typically process materials like galvanized steel, aluminum, and stainless steel. These materials are chosen for their durability, corrosion resistance, and ability to maintain structural integrity during shaping.

Q: How does an upright rack roll forming machine differ from standard models?

A: An upright rack roll forming machine is designed specifically for producing vertical storage rack components. It features specialized rollers and tooling to create precise angles and profiles required for racking systems, unlike general-purpose machines.

Q: What should I consider when choosing upright roll forming machine manufacturers?

A: Prioritize manufacturers with proven expertise in your industry, customization capabilities, and adherence to ISO certifications. Also, evaluate their after-sales support, machine durability, and client testimonials.

Q: Can upright roll forming machines handle high-strength materials?

A: Yes, advanced upright roll forming machines can process high-strength alloys and thick-gauge materials. Ensure the machine has robust rollers, adequate motor power, and precision alignment systems for such applications.

Q: What industries benefit most from upright rack roll forming machines?

A: These machines are essential for warehousing, logistics, and retail sectors that require customized storage solutions. They efficiently produce upright rack profiles for pallet racks, cantilever racks, and mezzanine systems.