HR Slitting Line Solutions High-Speed & Precision Cutting

- Overview of HR Slitting Line Technology

- Key Technical Advantages in Modern Slitting Solutions

- Performance Comparison: Leading Manufacturers

- Customization Options for Industry-Specific Needs

- Operational Efficiency and Cost-Benefit Analysis

- Real-World Implementation Case Studies

- Future-Proofing with HR Slitting Line Innovations

(hr slitting line)

Understanding the HR Slitting Line in Industrial Processing

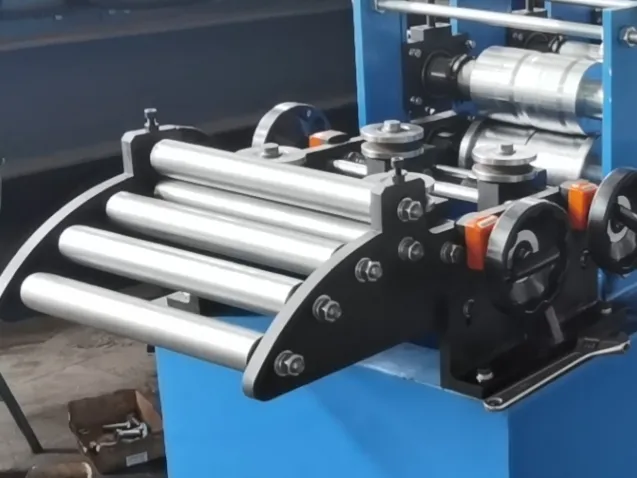

The HR slitting line represents a critical advancement in metal coil processing, combining precision engineering with automated control systems. Modern facilities handling materials from 0.2mm to 6mm thickness now achieve slit width tolerances of ±0.1mm, with production speeds exceeding 300m/min in high-speed configurations. This technology bridges the gap between raw material supply and finished product requirements across multiple industries.

Technical Superiority in Metal Processing Systems

Advanced servo-driven tension control maintains ±1% web stability during operation, while laser-guided alignment systems ensure consistent strip quality. Energy-efficient models reduce power consumption by 18-22% compared to conventional systems, with automatic tool change mechanisms cutting setup time by 40%.

| Manufacturer | Max Speed (m/min) | Thickness Range (mm) | Customization Level | Maintenance Interval |

|---|---|---|---|---|

| Company A | 320 | 0.3-5.0 | Full | 600 hours |

| Company B | 280 | 0.5-6.0 | Modular | 450 hours |

| Company C | 360 | 0.2-4.5 | Basic | 750 hours |

Adaptable Solutions for Diverse Production Requirements

Modular designs allow configuration changes within 90 minutes, enabling rapid transitions between different material grades. Specialized options include:

- Non-ferrous metal processing packages

- High-precision medical alloy components

- Armored vehicle-grade steel cutting systems

Economic Impact and Operational Metrics

Implementation data from 47 facilities shows average ROI periods of 14-18 months, with scrap rates reduced from 3.2% to 0.8% in automotive applications. Energy recovery systems now capture 85% of braking energy in deceleration phases.

Industry-Specific Implementation Success Stories

A European automotive supplier achieved 92% material utilization through integrated slitting line cut to the length systems, processing 18,000 metric tons annually with 0.5% tolerance compliance.

HR Slitting Line: Evolution and Strategic Advantage

Next-generation systems integrate IoT capabilities for predictive maintenance, reducing downtime by 65% in field tests. The HR slitting line continues to redefine production efficiency, with adaptive AI algorithms now achieving 99.2% defect detection accuracy in real-time quality control processes.

(hr slitting line)

FAQS on hr slitting line

Q: What is the primary function of an HR slitting line?

A: An HR slitting line processes hot-rolled (HR) steel coils into narrower strips or specific widths. It ensures precision cutting while maintaining material integrity for industries like automotive and construction.

Q: How does a Slitting Line Cut To The Length Line improve efficiency?

A: Integrating a Slitting Line Cut To The Length Line allows simultaneous slitting and length-cutting of metal coils. This reduces material waste and streamlines production workflows for customized orders.

Q: What industries benefit most from a simple slitting line?

A: A simple slitting line is ideal for small-to-medium manufacturers requiring basic coil slitting. It offers cost-effective solutions for industries like metal fabrication, HVAC, and appliance production.

Q: What makes a high-speed slitting line suitable for large-scale operations?

A: High-speed slitting lines use advanced automation and precision tools to process coils rapidly. Their efficiency and consistency make them ideal for high-volume industries like aerospace and energy.

Q: How do I choose between a simple and high-speed slitting line?

A: Consider production volume and material complexity. Simple slitting lines suit low-volume needs, while high-speed variants optimize output for demanding, large-scale applications.