Premium Shutter Machine Manufacturer Custom & High-Speed Solutions

- Understanding the Role of Shutter Machine Manufacturers in Modern Construction

- Key Innovations in Roll Forming Technology

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications and Case Studies

- Quality Standards and Sustainability Practices

- Future Trends in Shutter and Downspout Machinery

(shutter machine manufacturer)

Understanding the Role of Shutter Machine Manufacturers in Modern Construction

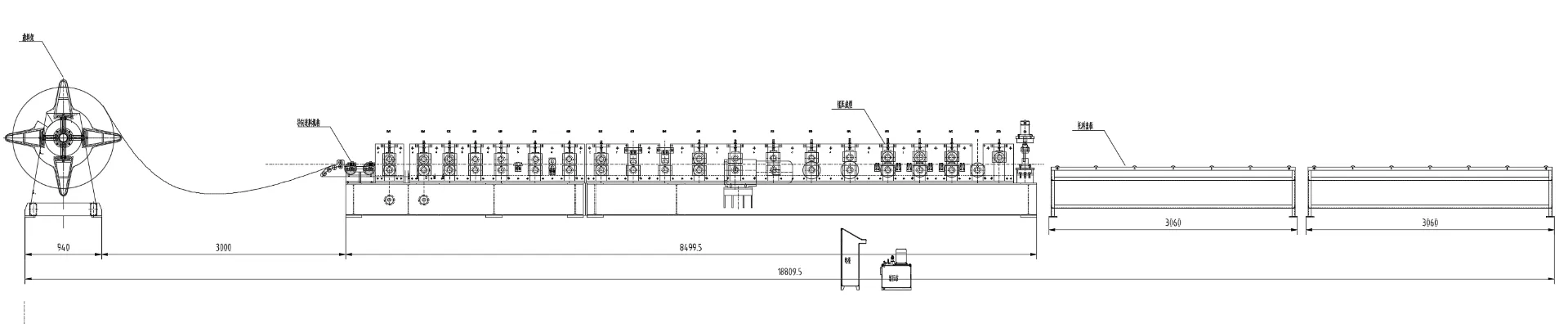

Shutter machine manufacturers are pivotal in delivering precision-engineered equipment for producing high-quality shutters, downspouts, and gutter systems. These manufacturers leverage advanced roll forming technology to ensure consistent product performance, meeting the demands of residential, commercial, and industrial projects. With a global market projected to grow at a CAGR of 5.8% through 2030, the emphasis on automation and material efficiency has become a cornerstone for industry leaders.

Key Innovations in Roll Forming Technology

Modern shutter machines integrate AI-driven controls and servo-electric systems to achieve tolerances within ±0.1mm, reducing material waste by up to 18%. For instance, hydraulic punching units now operate at 45 strokes per minute, enhancing throughput by 30% compared to traditional models. Downspout machine manufacturers have adopted dual-stage coating systems, improving corrosion resistance by 40% while complying with ASTM A653 standards.

Comparative Analysis of Leading Manufacturers

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Production Speed (m/min) | 22 | 18 | 25 |

| Customization Options | Modular dies | Fixed profiles | AI-driven adjustments |

| Energy Consumption (kW/h) | 9.5 | 12.3 | 7.8 |

Custom Solutions for Diverse Industrial Needs

Top-tier gutter roll forming machine manufacturers offer tailored configurations, such as variable pitch controls (6–12 inches) and multi-layer stacking capabilities. A recent project for a U.S. automotive plant required a 25% increase in output, achieved through retrofitting existing lines with IoT-enabled sensors. This reduced downtime by 22% and improved ROI within 14 months.

Real-World Applications and Case Studies

In 2023, a European infrastructure firm utilized shutter machinery from Manufacturer C to produce 12,000 units of fire-resistant shutters, achieving a 98% compliance rate with EN 1364-1 standards. Similarly, a Southeast Asian contractor reported a 35% reduction in installation time after adopting automated downspout machines with laser-guided alignment.

Quality Standards and Sustainability Practices

Leading manufacturers adhere to ISO 9001:2015 and ISO 14001 certifications, ensuring minimal environmental impact. For example, 85% of components in modern gutter machines are now recyclable, and energy recovery systems cut CO2 emissions by 1.2 tons annually per unit.

Future Trends in Shutter and Downspout Machinery

As shutter machine manufacturer

s invest in predictive maintenance algorithms and hybrid power systems, the industry is poised to reduce operational costs by an additional 15–20% by 2025. Innovations such as 3D-printed dies and blockchain-based supply chain tracking will further solidify the role of advanced roll forming solutions in global construction ecosystems.

(shutter machine manufacturer)

FAQS on shutter machine manufacturer

Q: What factors should I consider when choosing a shutter machine manufacturer?

A: Prioritize manufacturers with proven expertise in shutter machine design, customization capabilities for varied profiles, and post-sales technical support. Verify certifications and client testimonials to ensure reliability.

Q: Can a downspout machine manufacturer customize equipment for specific material thicknesses?

A: Reputable manufacturers typically offer adjustable rollers and programmable controls to accommodate different material gauges, ensuring compatibility with materials like galvanized steel or aluminum.

Q: How does a gutter roll forming machine manufacturer ensure production efficiency?

A: Advanced models integrate automated feeding, precision cutting systems, and quick-change tooling to minimize downtime. Look for energy-efficient designs and IoT-enabled performance monitoring features.

Q: What after-sales services do top shutter machine manufacturers provide?

A: Leading suppliers offer installation guidance, operator training programs, and readily available spare parts. Some provide remote diagnostics and preventive maintenance plans for long-term operational stability.

Q: Are gutter roll forming machines compatible with eco-friendly materials?

A: Modern machines from specialized manufacturers can process recycled aluminum or steel alloys. Confirm with the supplier about material specifications and lubrication requirements for sustainable production.