Automatic stud and track roll forming machines are designed to create metal studs and tracks used in wall framing, ceilings, and other structural applications. Traditionally, changing the size of the components required manual adjustments, which could be time-consuming and prone to errors. However, with the advent of change size automatic technology, operators can now adjust the machine settings with the PLC, allowing for rapid transitions between different sizes and profiles.

One machine can make multiple sizes, automatically adjust sizes, easy to operate, high production efficiency, and longer service life

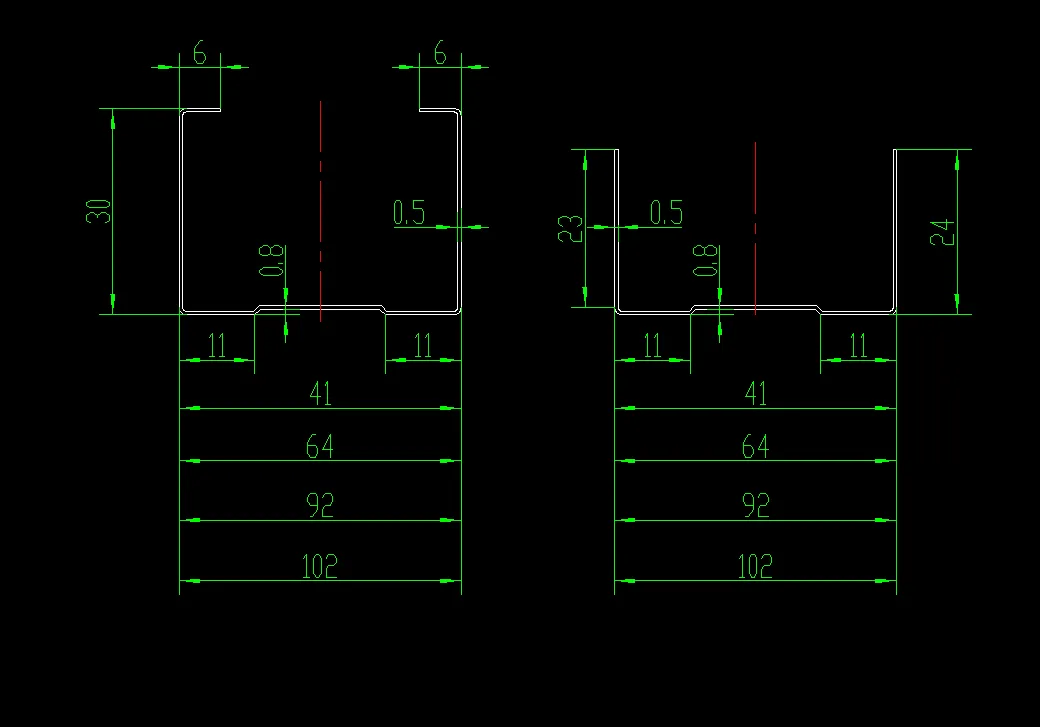

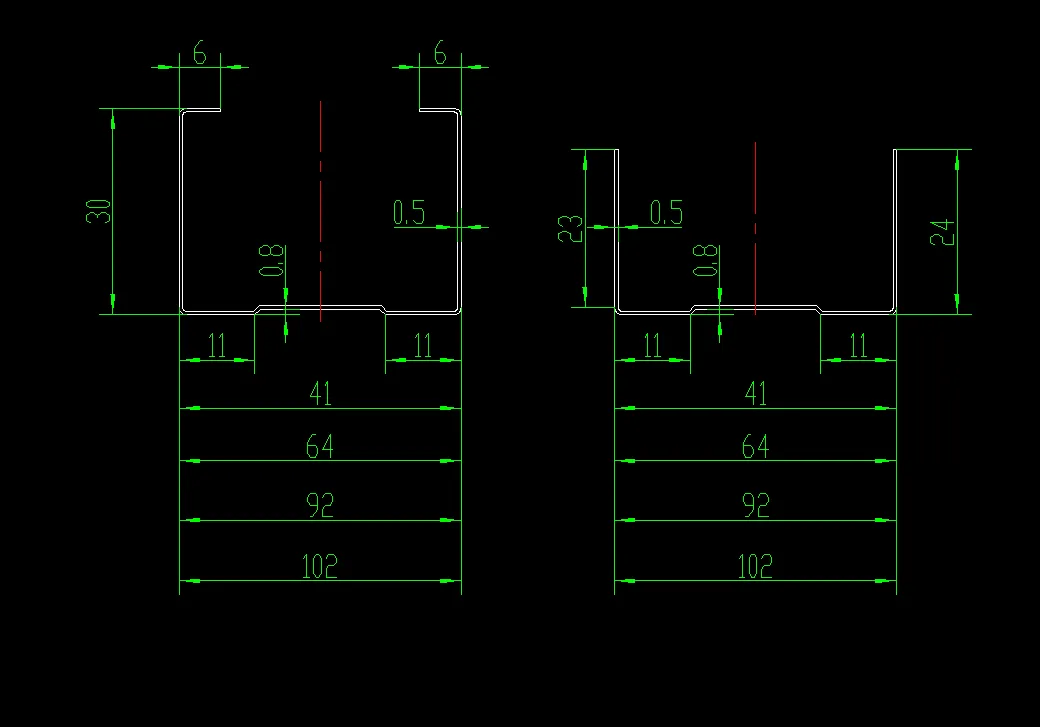

Drawings

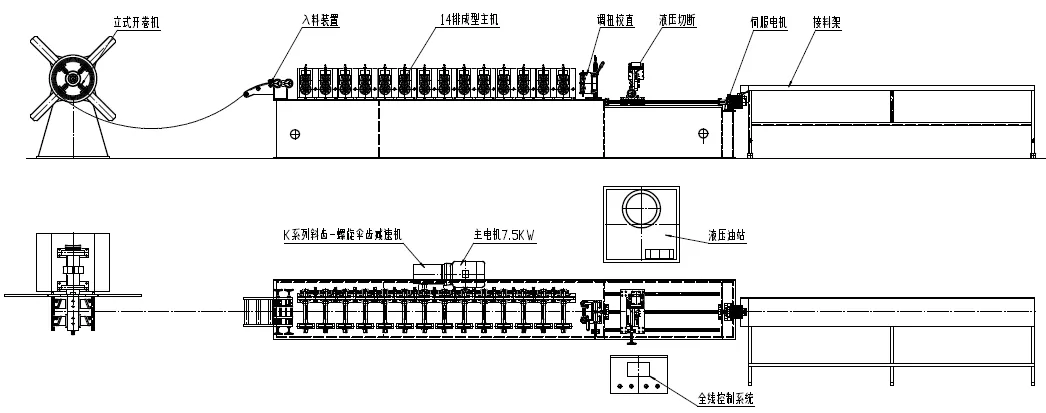

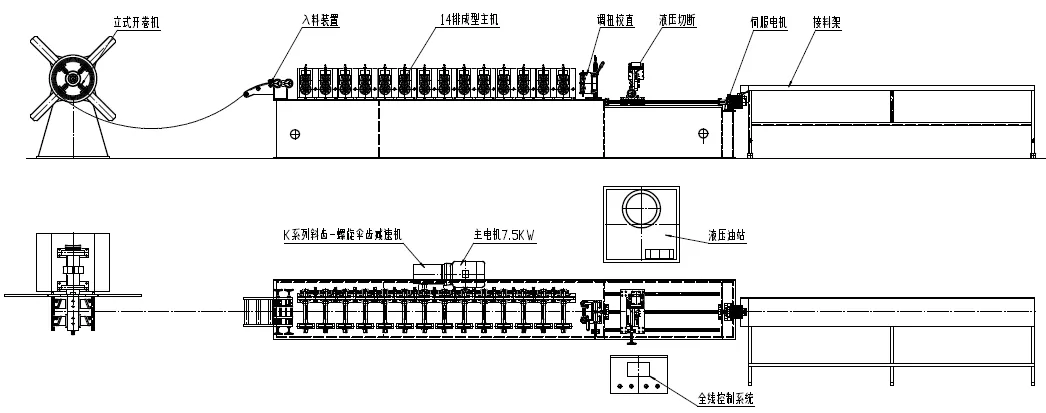

Processes and components

| Manuel decoiler |

x 1 set |

| Guiding machine |

x 1 set |

| Main roll forming machine |

x4 sets |

| Servo tracking cutting system |

x4 sets |

| Hydraulic station |

x 1 set |

| PLC Control system |

x 1 set |

| Run-out table (3M*2) |

x 1 set |

Working Process

|

Decoiler

1) Capacity: 3 tons

2). Manual decoiler

|

|

Material guiding

Input width adjustable

|

|

|

Roll forming machine

Matching material: Galvanized or PPGI

Material thickness range: 0.5-1.2mm

Forming speed: 15-50m/min

Main power:15kw

Hydraulic station:7.5kw+5.5kw+5.5kw

Servo power:2.3kw

Quantity of roller:15

Shaft Material and diameter:¢50 mm

material is 45CR

7.The way of driving:Gearbox

Controlling system: PLC

Voltage: 380V/ 3phase/ 60 Hz

10.Material of forming rollers: Cr12,HRC58-62

11.Material of cutter blade: Cr12 mould steel with quenched treatment,HRC 58-62℃

12.Servo tracking cutting

|

|

Control system

It adopts PLC to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

|

|

|

Hydraulic station

Motor power of hydraulic station: the power is 7.5Kw, and the hydraulic station drives the cutting system.

|

|

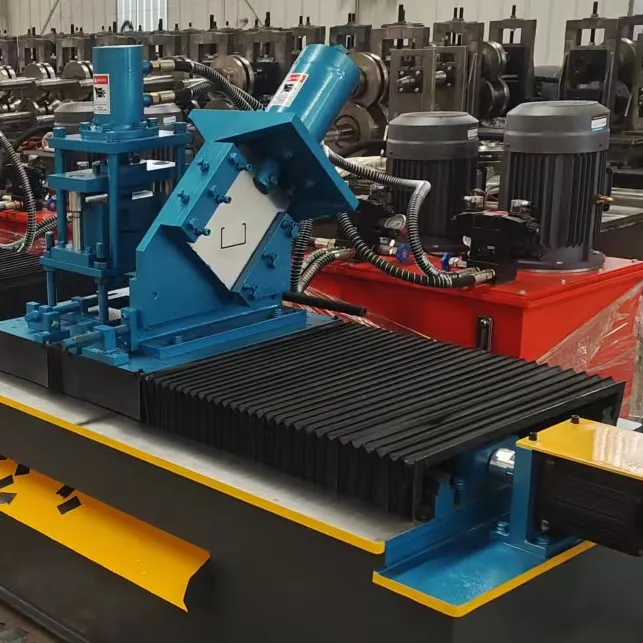

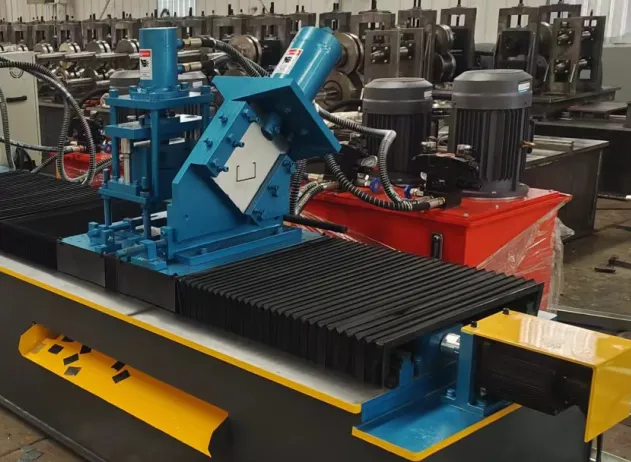

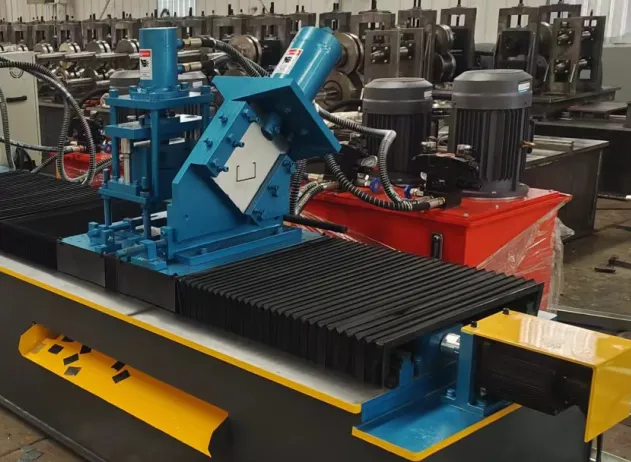

Servo track cutting system

1.Tolerance of length: +/- 1.5mm

2.Material of blade: CR12 with heat treatment

3.Length measuring: Automatic length measuring

4.Control: by setting on the PLC system

|

|

| |

Brand:

PLC: Xinjie

Low voltage components: Delixi

Inverter: Huichuan

Relay: Xinda

Switching power supply: Delta

|