Bulla automata et semita, volvunt machinas formandas ordinantur ad creandas bullas metallicas et vestigia in parietibus fabricandis, laquearia et aliis applicationibus structurarum adhibitis. Traditionaliter, mutato magnitudine partium compositiones manuales requirebat, quae tempus edax esse poterat et ad errores proclivior. Nihilominus, adveniente mutationis magnitudine technologiae automaticae, operarii nunc machinae occasus cum PLC componunt, permittens rapidas transitus inter varias magnitudines et profile.

Una machina plures magnitudines facere potest, automatice magnitudines accommodare, facile operari, altam efficientiam producendi, et diutius vitam agere

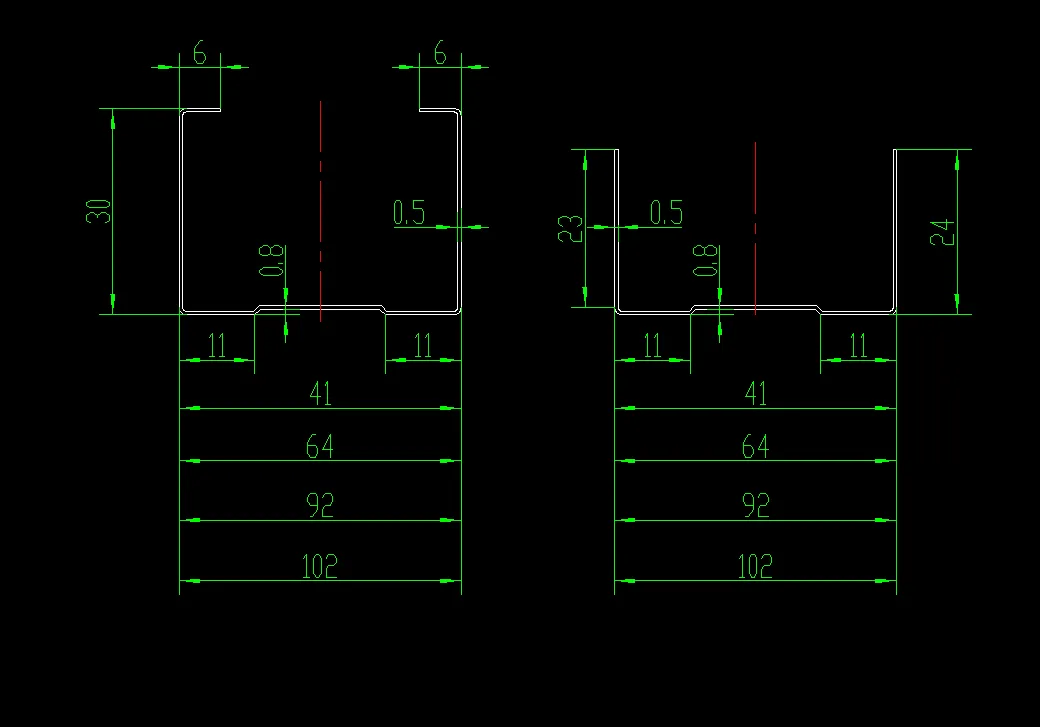

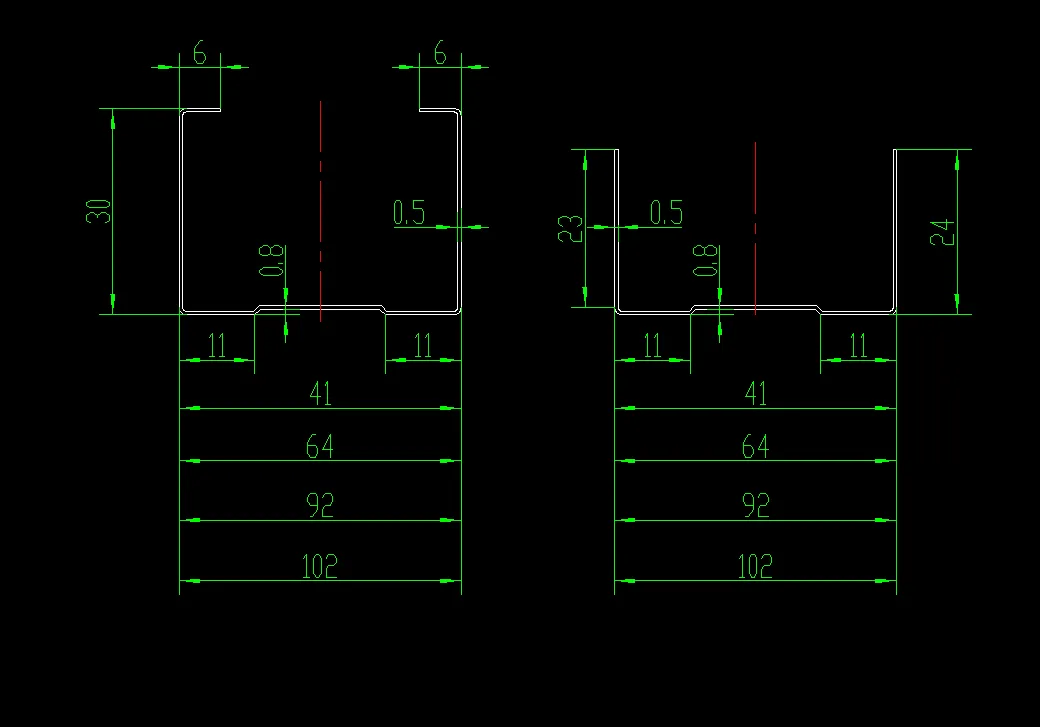

Drawings

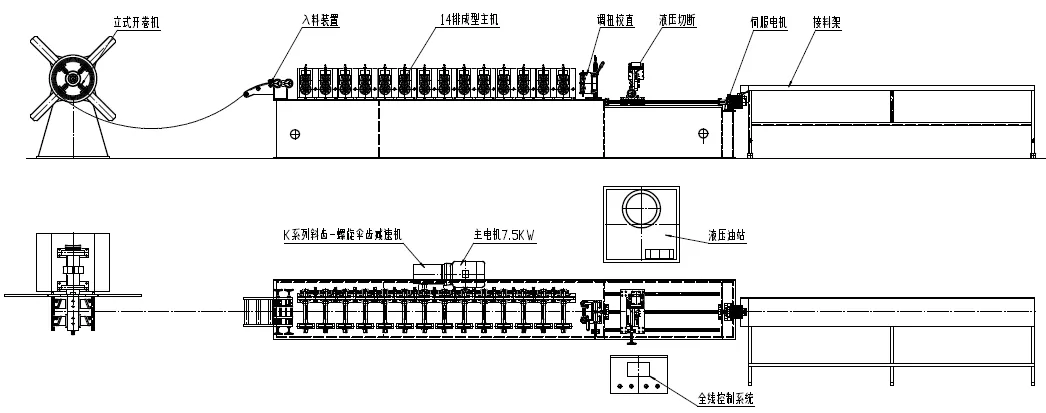

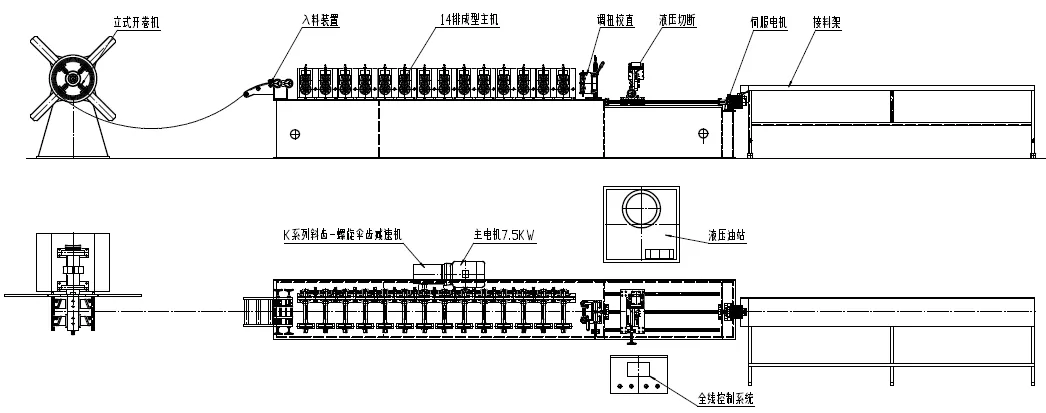

Processus et components

| Manual decoiler |

x 1 set |

| Apparatus guiding |

x 1 set |

| Pelagus volumine formatam machinam |

x4 sets |

| Servo tracking cutting system |

x4 sets |

| HYDRAULICUS station |

x 1 set |

| PLC Control system |

x 1 set |

| Currere de mensa (3M * II) |

x 1 set |

Processus working

|

Decoiler

1) Capacity: 3 tons

2). Manual decoiler

|

|

Materia guiding

Input width adjustable

|

|

|

Roll machinatio

Matching material: Galvanized vel PPGI

Crassitudo materialis range: 0.5-1.2mm

Formans celeritatem: 15-50m/min

Principalis potentia: 15kw

HYDRAULICUS statio: 7.5kw+5.5kw+5.5kw

Servo potentia: 2.3kw

Quantitas cylindro: 15

Material ac diam hastile: ¢50 mm

materia est 45CR

7. via pulsis: Gearbox

Systema moderantum: PLC

Voltage: 380V/ 3phase/ 60 Hz

10.Material formandi scutulis: Cr12,HRC58-62

11.Material of dromonis: Cr12 ferrum fingunt cum restincto treatment,HRC 58-62℃

12.Servo secandum sequi

|

|

Imperium systema

It adopts PLC to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

|

|

|

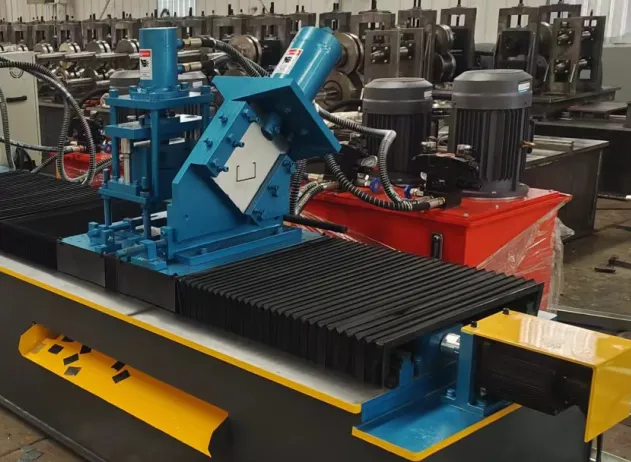

HYDRAULICUS station

Potentia motoris stationis hydraulicae: potentia est 7.5Kw, et statio hydraulicae systematis secans agit.

|

|

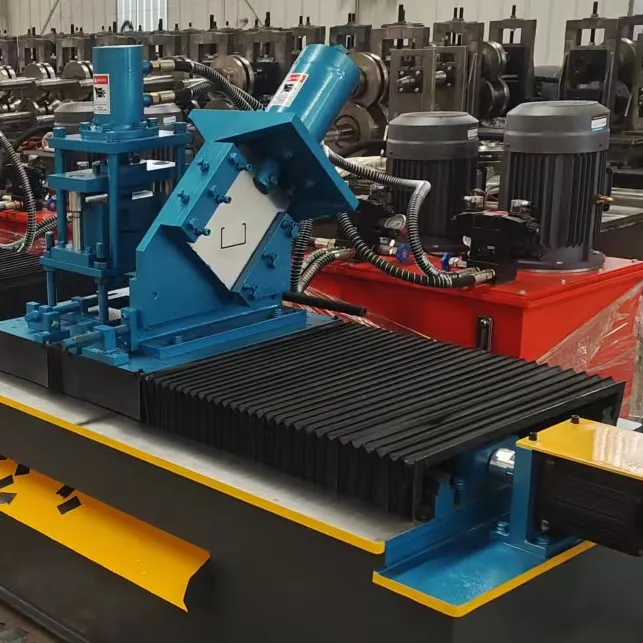

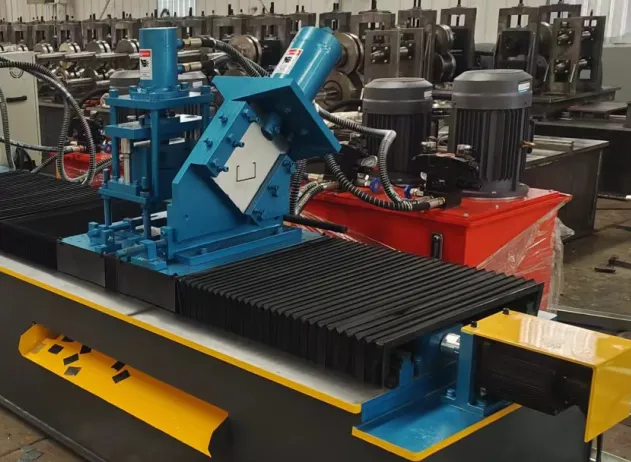

Servo inuestigandum systematis sectionis

1.Tolerance longitudinis: +/- 1.5mm

2.Material of ferrum: CR12 cum calor curatio

3.Length mensuræ: Lorem longitudinem mensurae

4.Control: ab occasu in PLC systema

|

|

| |

Notam:

PLC: Xinjie

Minimum voltage components: Delixi

Inverter: Huichuan

Nullam: Xinda

Copia virtutis switching: Delta

|