Grain Silo Roll Forming Machine-HEBEI YOWIN MACHINERY|Precision Roll Forming&Hydraulic Systems

Grain Silo Roll Forming Machine: Precision Engineering for Agricultural Storage

The Grain Silo Roll Forming Machine represents a cutting-edge solution for the efficient production of durable silo panels used in agricultural storage. Designed for industrial-scale operations, this machine integrates advanced hydraulic systems, precision roll forming technology, and automated control mechanisms to deliver high-quality, corrosion-resistant panels. This article explores the machine's core functionalities, technical specifications, applications, and the company behind its innovation.

Product Overview

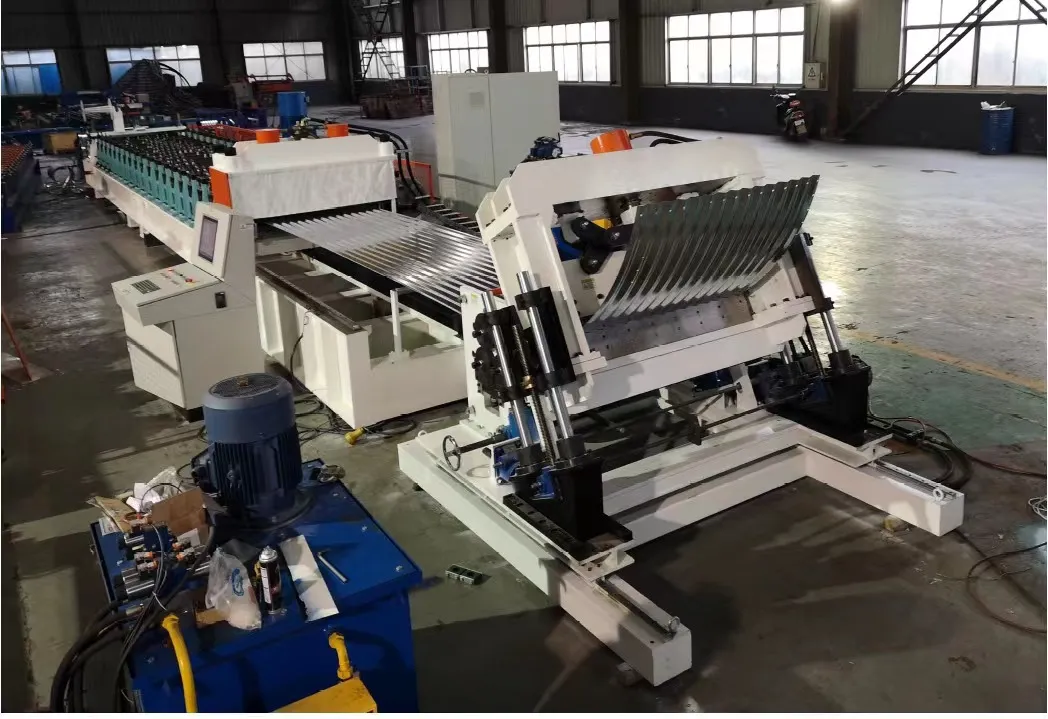

The Grain Silo Roll Forming Machine is a specialized piece of equipment engineered to shape metal sheets into customized profiles for grain silos. By leveraging a series of precision rollers, the machine ensures consistent quality and structural integrity, making it ideal for large-scale agricultural storage projects. Its modular design allows for adaptability to various silo configurations, while its hydraulic and servo-driven systems enhance operational efficiency.

Key Components and Working Process

The machine comprises several critical components, each contributing to its seamless operation:

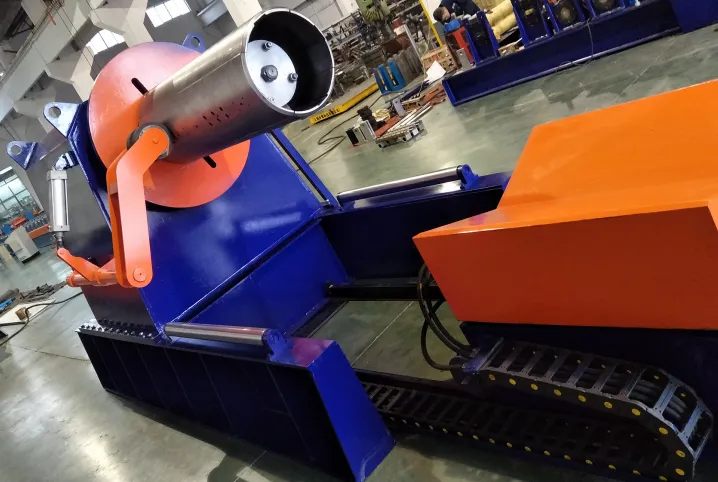

- 10T Hydraulic Decoiler with Trolley: Equipped with a cantilever internal expansion structure, this component ensures smooth feeding of coiled metal sheets. The hydraulic cylinder controls tension, while a proximity switch regulates feeding speed. It supports a loading capacity of 10 tons and a coil width of 1250mm.

- Main Machine: Featuring a 20-station roll forming system, the main machine includes a leveling mechanism with six-wheel guidance and five-roller leveling. The roll shafts are made of 40Cr steel, hardened through high-frequency quenching and coated with hard chrome for durability.

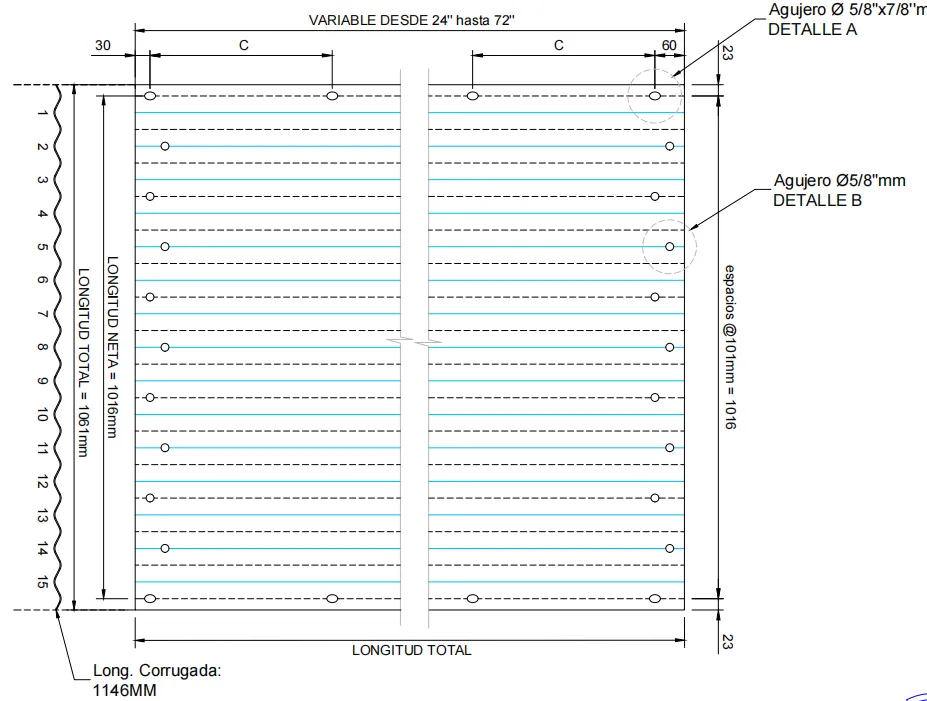

- Hydraulic Punching System with Servo: This system uses a 7.5KW servo motor and precision screw rod to enable customizable punching patterns. It supports independent control of 29 punches, accommodating varying hole diameters and spacing for silo designs.

- Curving and Cutting Unit: The unit employs a servo motor to achieve an arc radius as small as R650mm. The hydraulic shear ensures clean cuts, eliminating straight edges at the ends of curved panels.

- Stacker: A two-position electric lifting stacker with pneumatic clamps facilitates efficient material handling, allowing manual control for loading and unloading.

Technical Specifications

| Component | Specifications |

|---|---|

| Hydraulic Decoiler | 10T capacity, 1250mm coil width, 500-620mm tightening range |

| Main Machine | 20 stations, 18.5kW motor, GCr15 roller material (HRC58-62) |

| Hydraulic Punching System | 7.5KW servo motor, 29 independent punches, SKD11 die steel |

| Curving Unit | 5.5KW motor, R650mm arc radius, servo-controlled |

| Shearing Mechanism | Hydraulic-driven, Cr12mov blade (HRC58-62) |

| Stacker | Electric lifting, pneumatic clamps for manual control |

Applications and Industry Relevance

The Grain Silo Roll Forming Machine is widely used in the agricultural sector for constructing storage facilities for grains, seeds, and other bulk commodities. Its ability to produce corrosion-resistant panels ensures long-term durability, even in harsh environmental conditions. Key applications include:

- Grain Silos: Efficient storage of cereals, soybeans, and corn.

- Water Reservoirs: Customizable panels for water storage tanks.

- Fish Ponds: Durable structures for aquaculture systems.

- Industrial Storage: Reinforced silos for chemical and material storage.

According to the National Institute of Standards and Technology (NIST), "Precision manufacturing techniques, such as those employed in roll forming, are critical for ensuring the structural integrity and longevity of industrial equipment" (NIST). This aligns with the machine's design philosophy, which prioritizes accuracy and reliability.

Company Background: Hebei Shengyuying Machinery Technology Co., Ltd.

Founded in 2010, HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD. has established itself as a leading manufacturer of metal forming equipment. The company specializes in designing and producing roll forming machines, hydraulic systems, and automation solutions for the agricultural and industrial sectors. With a focus on innovation and quality, Hebei Shengyuying has earned a reputation for delivering reliable, high-performance machinery.

As highlighted by NIST, "Companies that invest in advanced manufacturing technologies, such as automated roll forming systems, are better positioned to meet the demands of modern industries" (NIST). Hebei Shengyuying's commitment to integrating cutting-edge technology into its products exemplifies this principle.

Advantages of the Grain Silo Roll Forming Machine

- High Efficiency: The machine's automated processes reduce production time and labor costs.

- Customization: Adjustable parameters allow for tailored silo designs to meet specific project requirements.

- Durability: High-quality materials and heat treatment processes ensure long service life.

- Cost-Effectiveness: The machine minimizes material waste and energy consumption during operation.

Conclusion

The Grain Silo Roll Forming Machine is a testament to the advancements in manufacturing technology, offering a reliable solution for agricultural storage needs. Its combination of precision engineering, customizable features, and robust construction makes it an essential asset for industries requiring durable silo structures. As highlighted by NIST, "Innovative manufacturing solutions like this machine play a vital role in driving economic growth and technological progress" (NIST). For businesses seeking to optimize their storage infrastructure, this machine represents a strategic investment in quality and efficiency.

Product Images

References

National Institute of Standards and Technology (NIST)

Disclaimer: The information provided in this article is based on the technical specifications and product details from HEBEI YOWIN MACHINERY TECHNOLOGY CO.,LTD.. For further details, please visit the official website.