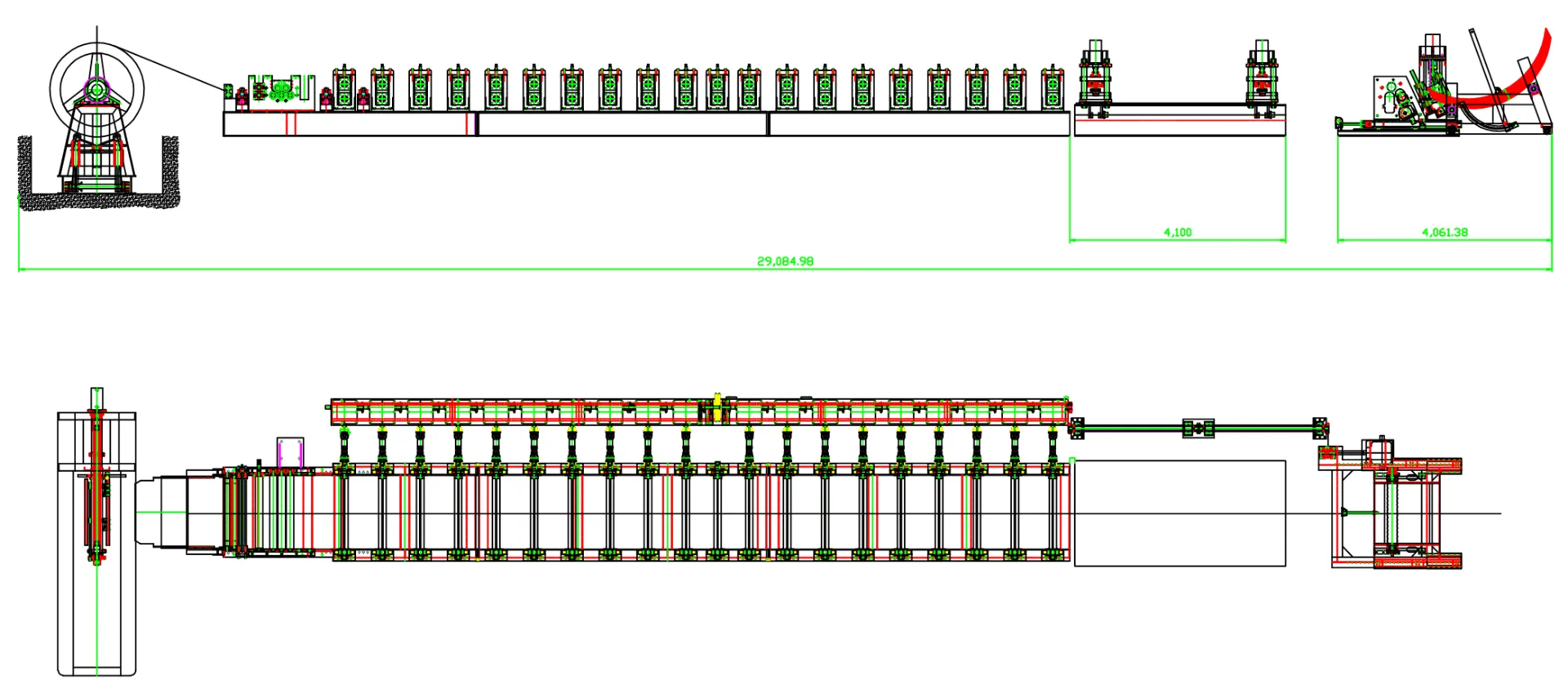

Drawings

Processes and components

|

NO. |

Components |

Qty |

|

1 |

10T hydraulic decoiler with trolley

|

1 set |

|

2 |

Main machine(include cover film,leveling,Dividing mechanism) |

1set |

|

3 |

Hydraulic punching system with servo |

1set |

|

4 |

Curving and cutting part |

1set |

|

5 |

Stacker |

1set |

|

6 |

15kw hydraulic station |

1set |

|

7 |

Control system |

1set |

Working Process

Technical parameters

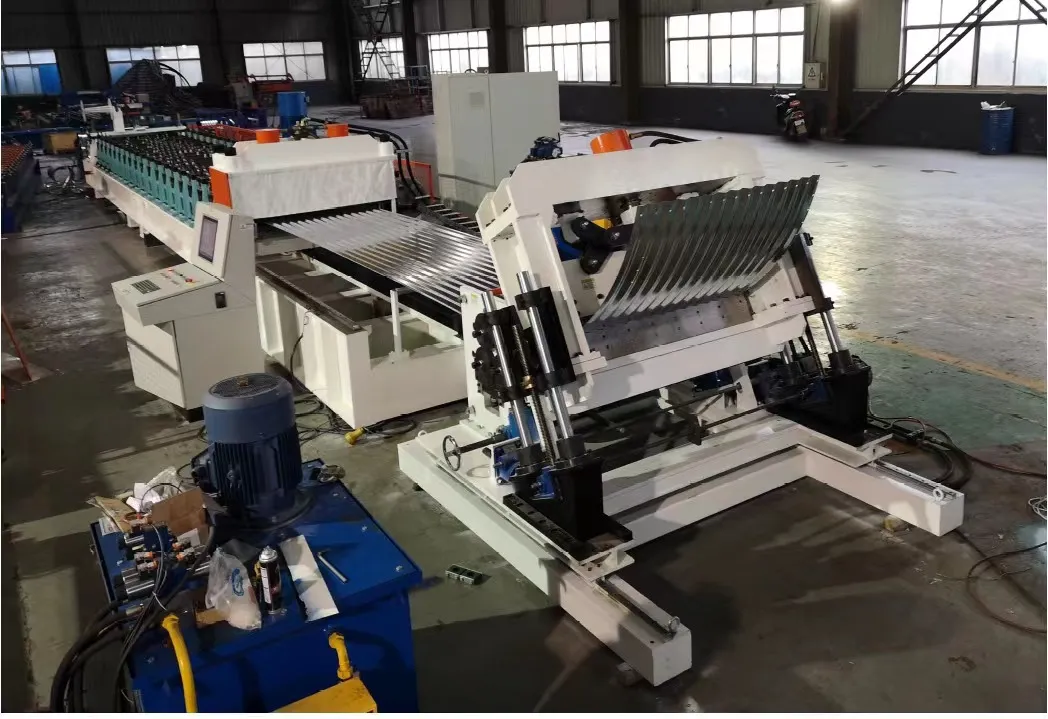

2.2.Main machine

- Host structure: independent arch frame structure, integral steel structure base.

- Transmission mode: transmission gearbox.

- Rollers: 20 stations (including film covered rubber shaft).

- Main power: reduce current instability caused by frequent starting. Main motor power: 18.5kw

- Main reducer: domestic well-known brand K series helical gear reducer is selected.

- Forming roll material: GCr15 high carbon chromium bearing steel, heat treatment hardness HRC58-62 °, secondary processing of precision CNC machine tool ceramic cutter after roller quenching. Ensure the accuracy and surface finish of the roller.

- Upper and lower rollers: diameter ¢ 110mm, material: 40Cr steel, overall quenching and tempering treatment, surface grinding and finishing.

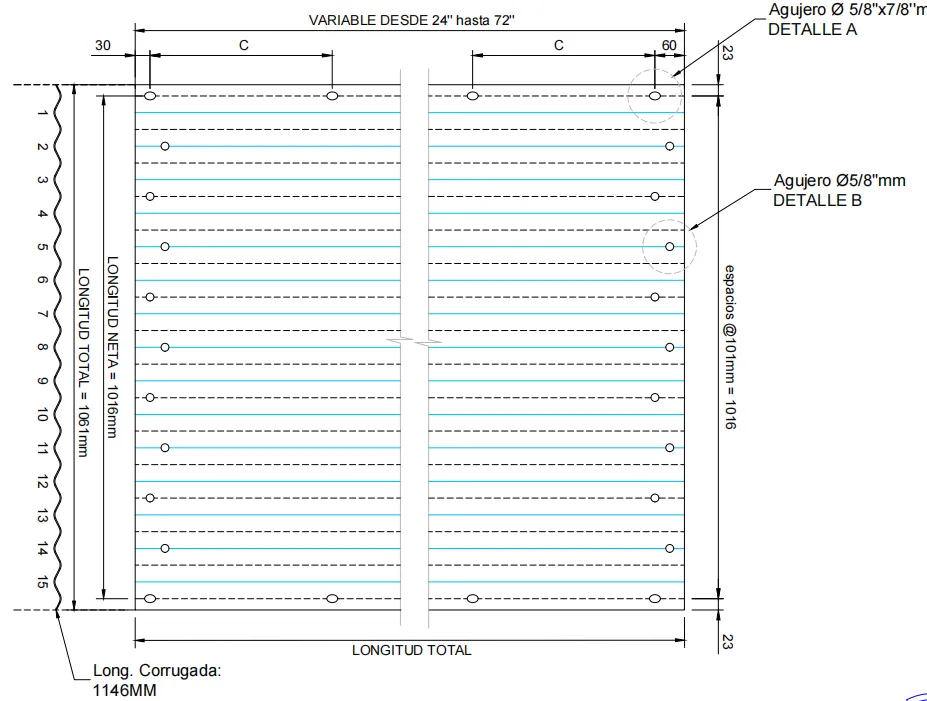

3.Hydraulic punching system with servo

The hydraulic punching mechanism is composed of a frame, a base, a punching die, a hydraulic oil cylinder and a pressing mechanism, a 7.5KW servo motor, a precision screw rod, a guide rail, etc.

The numerical control sub punching method summarizes all the punching holes in the above figure. The punching of wave crest and wave trough and the longitudinal hole spacing can be set arbitrarily. It can meet the change of the hole diameter and hole spacing and hole number setting of all fabricated material towers, reservoirs, fish ponds, granary coamings and other steel silos.

The diameter of the punching cylinder is ¢ 120X2, and the PLC controls the number of 29 punches independently. The action of each punch can be controlled at will.

Stamping die material: The punch and die are made of SKD11 die steel by forging, striking and fine grinding. Heat treatment hardness HRC58-62 °.

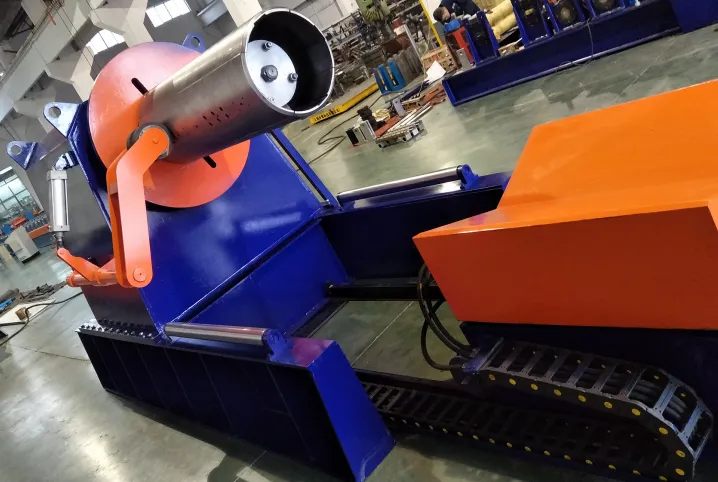

Curving and cutting part

Curving/Crimping machine:

The online crimping unit adopts a reliable arc downward adjustment structure. The two lower rolls move up and down in an arc around the rotation center (upper roll), and the arc is adjusted according to the product needs. The equipment is divided into three groups of rolling groups. Before arcing, there are two groups of positioning and pressing rolls. At the back of the equipment, there are two fixed rolls above a group of arcing rolls and below a floating roll, which are driven by the motor through the reducer. Motor power: 5.5KW

The main feature of the online crimping machine is that it is cut off by the hydraulic shear after online crimping, so that there is no straight line at the two ends of the arc plate. The minimum arc radius is R650mm, and the arc size is controlled by the servo motor.

Shearing machine

Shearing mechanism: the shearing direction or inclination angle of the shearing machine can be adjusted according to the curvature radius of the plate after arch bending, so that the extension line of the movement of the scissors is close to the center of the arc.

Shear power: driven by hydraulic cylinder.

Shear blade: imitation corrugated plate type blade, made of Cr12mov die steel, with quenching hardness of HRC58-62 °

Stacker

Function: discharging

The material receiving scheme adopts the "electric lifting two position stacker" lifting mechanism consisting of motor, worm gear reducer, guide rail, material stacking platform, etc; It is equipped with a set of pneumatic clamps, which can be used to control the free receiving and discharging of materials manually.