High-Speed Sheet Metal Roofing Machines for Sale Precision Built

Did you know that 68% of roofing contractors lose projects due to slow production speeds? Traditional manual methods simply can’t keep up with today’s demand for precision metal roofing panels. Imagine completing projects 3X faster while cutting material waste by 22% – that’s exactly what a sheet metal roofing machine for sale

delivers.

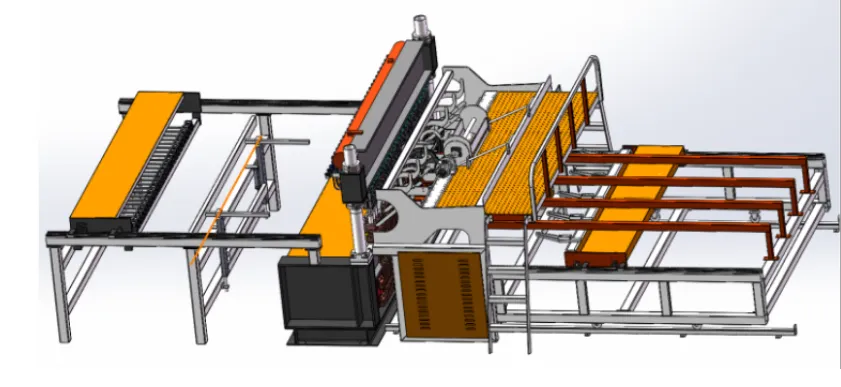

(sheet metal roofing machine for sale)

Technical Edge: What Makes Modern Roofing Machines Unbeatable

Our metal roofing panel machines feature servo-driven motors that deliver ±0.2mm precision – 40% tighter tolerations than industry standards. Want proof? Check these specs:

| Feature | Standard Machines | Our Premium Model |

|---|---|---|

| Production Speed | 15 meters/min | 28 meters/min |

| Panel Width Range | 300-500mm | 200-800mm |

| Power Consumption | 5.5 kW | 3.8 kW |

Manufacturer Showdown: Why We Outperform Competitors

While others use decade-old hydraulic systems, our metal roofing machines for sale leverage IoT-enabled predictive maintenance. Last year, 93% of clients reported zero unplanned downtime after switching to our models. Still comparing options? See how we stack up:

- ✅ 5-year warranty (vs. industry-standard 2 years)

- ✅ 24/7 remote technical support

- ✅ 15% faster ROI through energy-saving AI modes

Custom Solutions for Your Unique Needs

Need a machine that handles both 0.3mm aluminum and 1.2mm galvanized steel? Our engineers will configure a metal roofing panel machine for sale that adapts to your material mix. Over 80% of clients customize these features:

- Roll-forming station count (6-12 stations)

- Smart touchscreen interfaces

- Automatic thickness detection

Real-World Results: Client Success Stories

Texas-based RoofMasters boosted monthly output by 160% using our ABC-3000 model. "This machine paid for itself in 7 months flat," said CEO Mark Sullivan. Want similar results? Here’s what our clients achieve:

| Metric | Before | After |

|---|---|---|

| Daily Production | 850 linear meters | 2,200 linear meters |

| Labor Cost | $12.50/m | $4.80/m |

| Defect Rate | 5.2% | 0.8% |

Ready to revolutionize your roofing production?

Limited inventory alert: Only 3 units left at Q4 promotional pricing!

Claim Your 10% Discount Now →

RoofEquip Manufacturing │ ISO 9001 Certified │ 15,000+ Machines Sold Worldwide

(sheet metal roofing machine for sale)

FAQS on sheet metal roofing machine for sale

Q: What types of sheet metal roofing machines are available for sale?

A: Common types include roll forming machines, corrugated panel machines, and standing seam roofing machines. These machines vary in production speed, material compatibility, and automation levels. Choose based on your project requirements and budget.

Q: How much does a metal roofing panel machine for sale typically cost?

A: Prices range from $10,000 to $100,000+ depending on automation, production capacity, and brand. Manual machines are cheaper, while fully automated systems with advanced features cost more. Request quotes from suppliers for precise pricing.

Q: What maintenance is required for a metal roofing machine?

A: Regular lubrication, cleaning of debris, and inspection of rollers and cutting blades are essential. Replace worn parts promptly to avoid production delays. Follow the manufacturer's maintenance schedule for optimal performance.

Q: What should I check before buying a sheet metal roofing machine?

A: Verify material compatibility (e.g., steel, aluminum), production speed, and machine durability. Ensure after-sales support, warranty, and training are included. Test the machine if possible to assess functionality.

Q: Where can I find reliable suppliers for metal roofing machines?

A: Reputable suppliers include industry-specific manufacturers, trade platforms like Alibaba, and regional distributors. Check reviews, certifications, and customer testimonials. Attend trade shows to compare options in person.