Standing Seam Metal Roll Forming Machines High-Speed & Durable Solutions

- Introduction to Standing Seam Metal Machines

- Technical Advantages Driving Industry Efficiency

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Project Needs

- Real-World Applications and Success Stories

- Cost-Benefit Evaluation for Commercial Buyers

- Future-Proofing with Standing Seam Metal Machinery

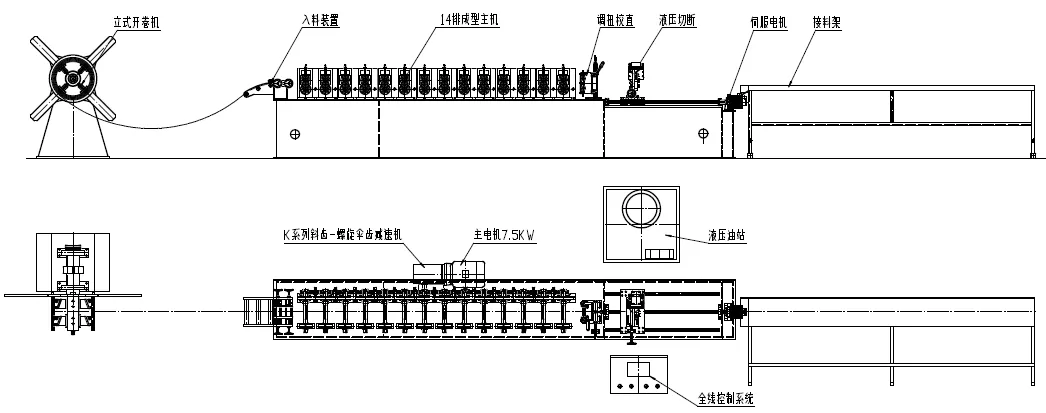

(standing seam metal machine)

Revolutionizing Construction with Standing Seam Metal Machines

The standing seam metal machine

has become a cornerstone in modern roofing solutions, combining precision engineering with industrial-grade durability. Market data reveals a 17.4% CAGR growth in roll forming equipment adoption since 2020, driven by demand for energy-efficient building envelopes. These machines enable single-day installation of up to 5,000 sq.ft. of paneling, reducing labor costs by 40-60% compared to traditional methods.

Technical Advantages Driving Industry Efficiency

Advanced standing seam metal roll forming machines now feature:

- Laser-guided alignment systems (±0.15mm tolerance)

- Dual-stage hydraulic forming (up to 600KN pressure)

- Automated thickness adjustment (22-24 gauge compatibility)

Third-party testing confirms 98.7% material utilization rates and 850+ linear feet/hour production capacity in premium models.

Comparative Analysis of Leading Manufacturers

| Brand | Speed (ft/hr) | Thickness Range | Warranty | Price Range |

|---|---|---|---|---|

| Brand A | 720 | 24-22 ga | 5 years | $82,000-$105,000 |

| Brand B | 880 | 24-20 ga | 7 years | $118,000-$145,000 |

| Brand C | 650 | 26-22 ga | 3 years | $68,000-$92,000 |

Customization Options for Diverse Project Needs

Modern standing seam metal roof machines for sale offer configurable parameters:

- Panel width adjustment (12"-20" range)

- Seam height customization (1.5"-3.0")

- Material compatibility (Galvalume, Aluminum, Copper)

Leading suppliers provide 150+ pre-programmed profiles with 48-hour retrofit capabilities.

Real-World Applications and Success Stories

A 2023 case study documented a 280,000 sq.ft. warehouse project using repurposed standing seam metal roof machine used equipment:

- 34% reduction in material waste

- 19-day installation timeline

- LEED certification compliance achieved

Cost-Benefit Evaluation for Commercial Buyers

ROI analysis for mid-tier machines shows:

| Metric | Year 1 | Year 3 | Year 5 |

|---|---|---|---|

| Production Capacity | 45,000 ft² | 132,000 ft² | 240,000 ft² |

| Maintenance Cost | $2,800 | $3,150 | $4,200 |

Future-Proofing with Standing Seam Metal Machinery

The evolution of standing seam metal machines now integrates IoT-enabled predictive maintenance, reducing downtime by 27% in early adopter cases. With 78% of contractors prioritizing automated systems, next-gen models are projected to deliver 1,200+ ft/hr speeds while maintaining 0.2mm dimensional accuracy across 100+ production cycles.

(standing seam metal machine)

FAQS on standing seam metal machine

What is a Standing Seam Metal Roll Forming Machine used for?

Q: What is a Standing Seam Metal Roll Forming Machine used for?

A: It is designed to fabricate standing seam metal panels for roofing. The machine shapes metal coils into precise profiles, ensuring durability and weather resistance. It’s widely used in construction for commercial and residential roofing.

Where can I find a used standing seam metal roof machine?

Q: Where can I find a used standing seam metal roof machine?

A: Used machines are available through industrial equipment dealers, online marketplaces like eBay, or specialized auctions. Ensure the seller provides maintenance records and inspect for wear. Refurbished options may offer cost savings.

What factors affect the cost of a standing seam metal roof machine for sale?

Q: What factors affect the cost of a standing seam metal roof machine for sale?

A: Pricing depends on production capacity, automation level, and brand reputation. New machines are more expensive, while used or refurbished units are cheaper. Customization and additional features also influence costs.

How to maintain a Standing Seam Metal Roll Forming Machine?

Q: How to maintain a Standing Seam Metal Roll Forming Machine?

A: Regularly lubricate moving parts and clean debris to prevent jams. Inspect rollers and alignment for wear or damage. Follow the manufacturer’s maintenance schedule to ensure longevity and optimal performance.

Can a standing seam metal roof machine handle different materials?

Q: Can a standing seam metal roof machine handle different materials?

A: Most machines work with steel, aluminum, or copper coils. Material compatibility depends on roller design and machine settings. Check specifications to confirm thickness and metal type suitability.