A Steel Coil Simple Leveling and Cutting Machine is a specialized piece of equipment designed to process steel coils. It levels the coils to ensure a flat surface and cuts them into specified lengths. This machine is essential in industries where precision and quality of steel sheets are critical, such as automotive, construction, and manufacturing.

Processes and components

| 5T manual decoielr | x1 set |

| Cut to the length machine | x1 set |

| Hydraulic cutting system | x1 set |

| Hydraulic station | x1 set |

| PLC Control system | x1 set |

Working Process

Technical parameters

5 T hydraulic decoiler with trolley

1.Decoiler form:5T

2.ID of feeding Coil:φ508㎜,or φ610㎜

3.Max width:1250㎜

4.Max weight :5T

5.Material:Aluminum and zinc plate galvanized plate color steel plate low carbon steel

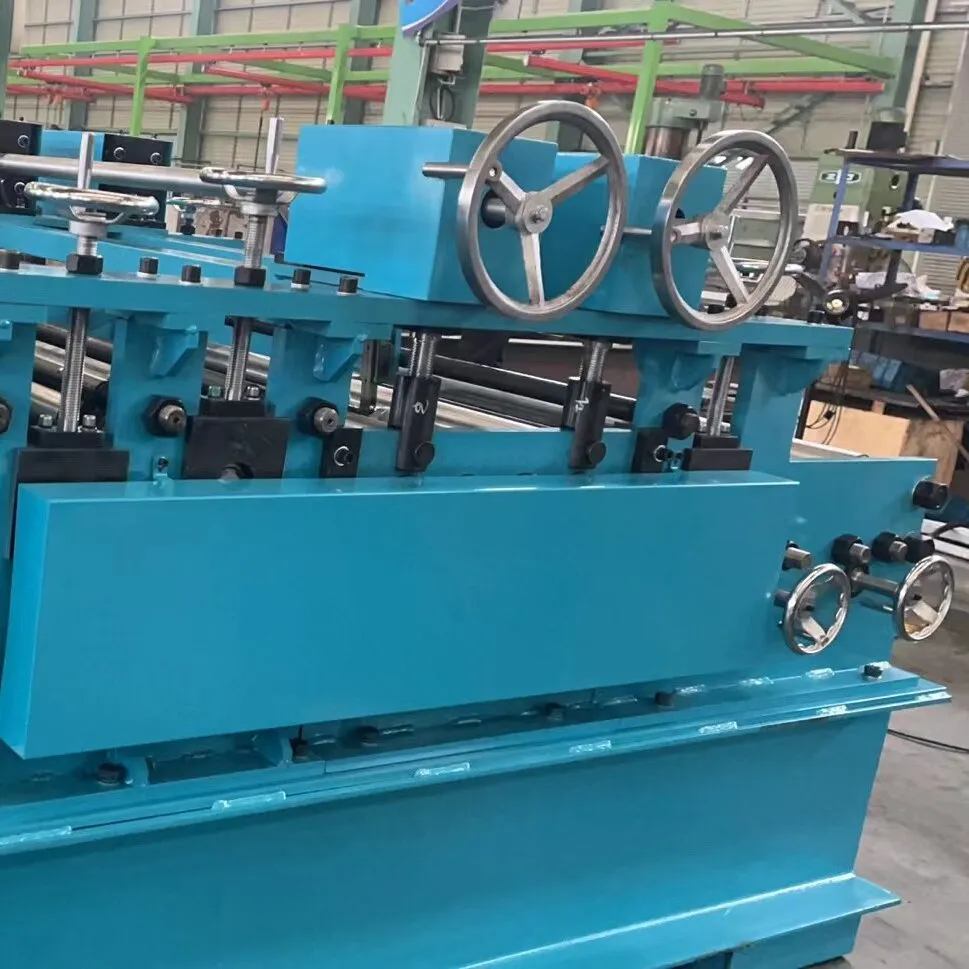

1220mm cut to the length machine

input :1220mm

Thickness: 0.4-1.5mm use for Q235-550

Rollers :7 up 8down

Shaft: Φ85mm

Wall panel: 25mm, A3 400H steel frame

Power: 5.5 kw

Speed: 16m/min

Hydraulic power:5.5kw, 21MPa.

Driven :chain

Cutting blade: Cr12

Voltage, Frequency, Phase: 220 V, 60 Hz, 3Phase (this is can depend on customer request)

Cutting

1.Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start.

2.Material of blade: CR12

3.Length measuring: Automatic length measuring

4.Tolerance of length: 10+/- 1.5mm

PLC control system

1.Voltage, Frequency, Phase: 220 V, 60 Hz, 3Phase (this is can depend on customer request)

2. Control panel: Button-type switch and touch screen

3.PLC :Delta

4.Frequency converter: DELTA

Key features of a Steel Coil Simple Leveling and Cutting Machine typically include:

- Automatic Leveling: The machine uses rollers to flatten the steel coil, removing any bends or warps.

- Precision Cutting: Equipped with cutting tools that ensure accurate and clean cuts to the desired length.

- User-Friendly Controls: Most machines come with intuitive control panels for easy operation.

- Durability: Built with robust materials to withstand heavy-duty use and ensure longevity.

The benefits of using this machine include:

- Increased Efficiency: Automating the leveling and cutting process saves time and labor costs.

- Improved Quality: Ensures that the steel sheets produced are flat and cut to precise dimensions, reducing waste and rework.

- Versatility: Can handle various sizes and thicknesses of steel coils, making it suitable for different applications.

- Enhanced Safety: Modern machines are designed with safety features to protect operators during the leveling and cutting processes.