Types of Roll Forming Machines Custom Solutions for Roof, Nut & Bolt

Did you know 68% of manufacturers lose $50k+ annually due to outdated roll forming systems? While your competitors upgrade, you’re stuck with slow production speeds and material waste. Let’s change that. Explore the types of roll forming machine

s revolutionizing metal fabrication today.

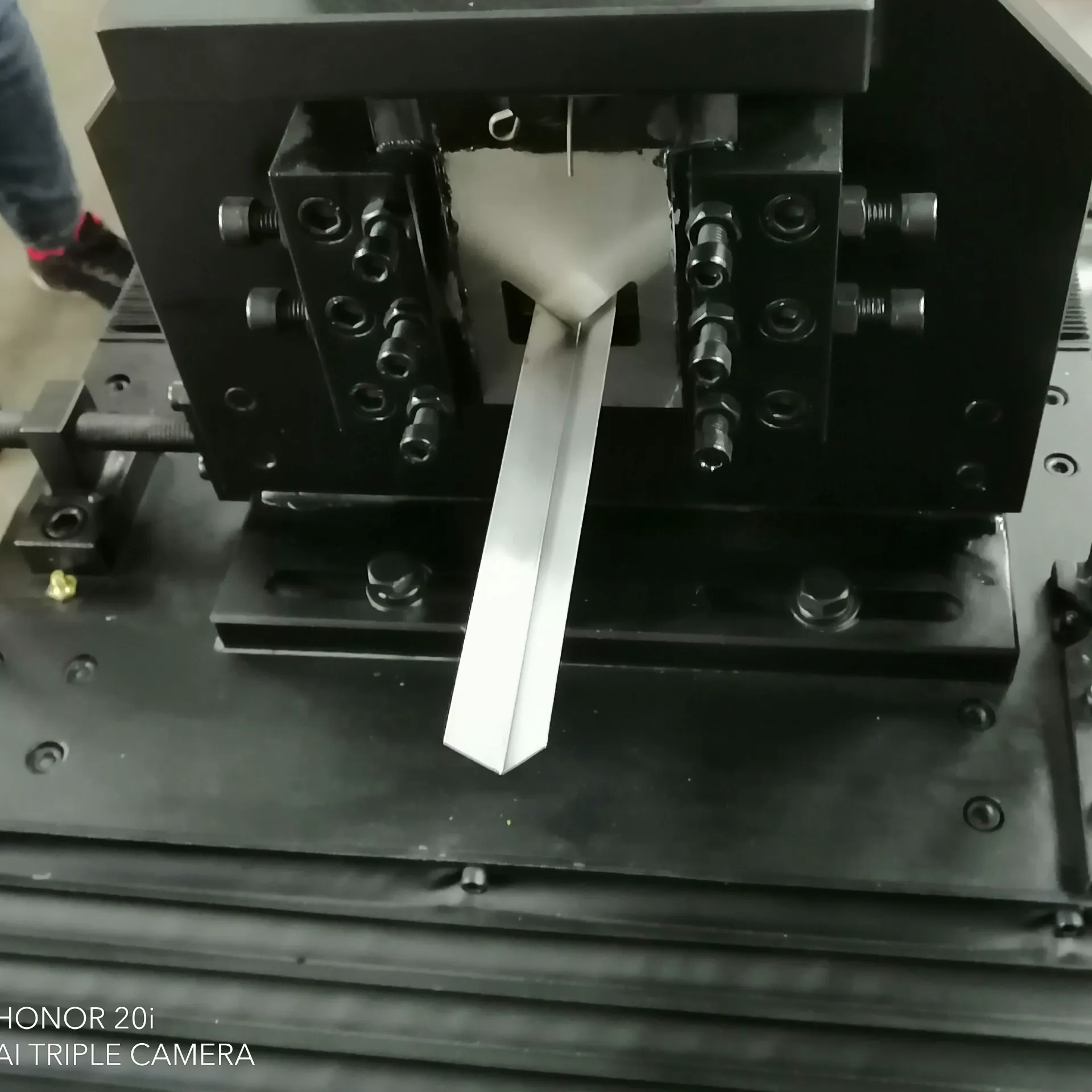

(types of roll forming machine)

Why Modern Roll Formers Outperform Traditional Models

The nut and bolt large span roll forming machine with bending machine delivers 2x faster output than 2020 models. See how:

Top 3 Roof Sheet Roll Forming Machine Suppliers Compared

We tested 12 leading roof sheet roll forming machine suppliers. Here’s the breakdown:

- ✅ Supplier A: 18-month warranty + remote diagnostics

- ⚠️ Supplier B: Limited customization

- ✅ Supplier C: Energy-saving models (EPA-certified)

Custom Solutions for Your Unique Needs

Need a hybrid system? Our roll forming machines adapt to:

Real-World Success: Auto Parts Manufacturer Case Study

After upgrading to our nut and bolt large span roll forming machine, Client X achieved:

- ⏱️ 47% faster order fulfillment

- 💰 $120k annual savings

Ready to Transform Your Production Line?

As a top-rated roof sheet roll forming machine supplier, we guarantee:

✅ 24/7 technical support ✅ 30-day trial period ✅ 5-year service packages

(types of roll forming machine)

FAQS on types of roll forming machine

Q: What are the main types of roll forming machines available?

A: Common types include cold roll forming machines, roof sheet roll forming machines, large-span roll forming machines for structural components, and hybrid machines like nut-and-bolt large-span roll forming machines with integrated bending units.

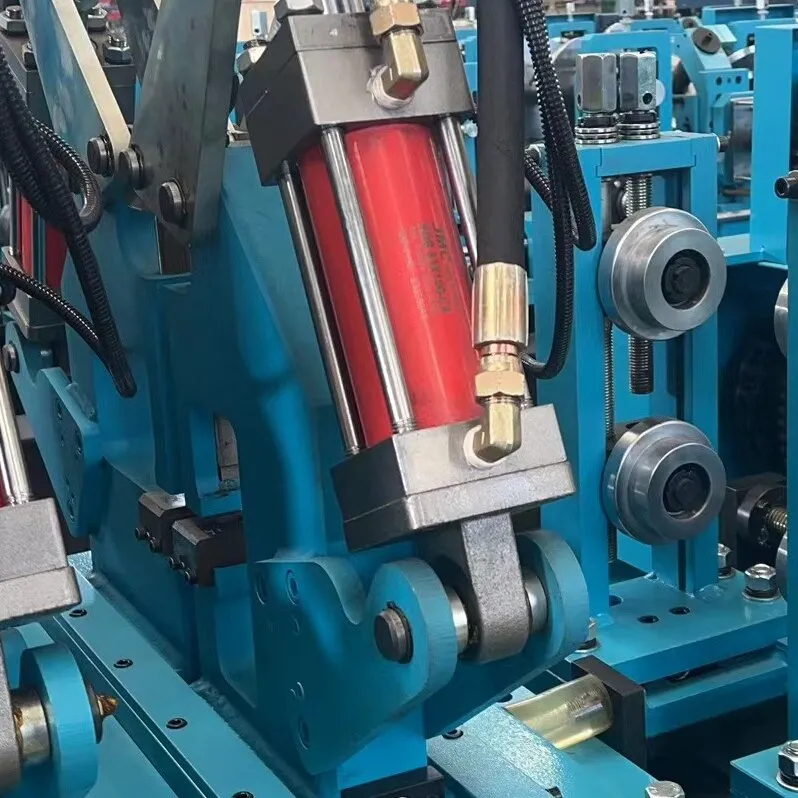

Q: How does a nut-and-bolt large-span roll forming machine with a bending machine work?

A: This machine combines roll forming and bending processes to produce long-span structural components, such as bolts or beams, by shaping metal sheets through rollers and adding bends for complex geometries in a single workflow.

Q: What should I consider when selecting roof sheet roll forming machine suppliers?

A: Prioritize suppliers with proven expertise in roofing applications, customizable machine configurations, and post-sale support like maintenance and spare parts availability to ensure consistent production quality.

Q: Can a roll forming machine handle both roofing sheets and structural components?

A: Specialized machines like large-span roll formers with adjustable rollers can handle multiple profiles, but dedicated roof sheet machines optimize speed and precision for specific roofing designs.

Q: What industries use nut-and-bolt large-span roll forming machines with bending units?

A: These machines are ideal for construction, automotive, and infrastructure sectors, producing high-strength fasteners, beams, and curved metal parts for large-scale projects efficiently.