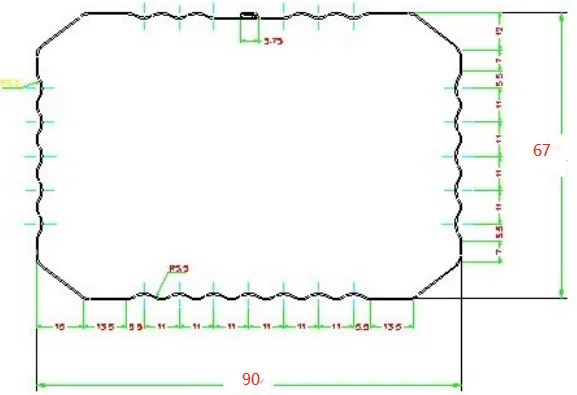

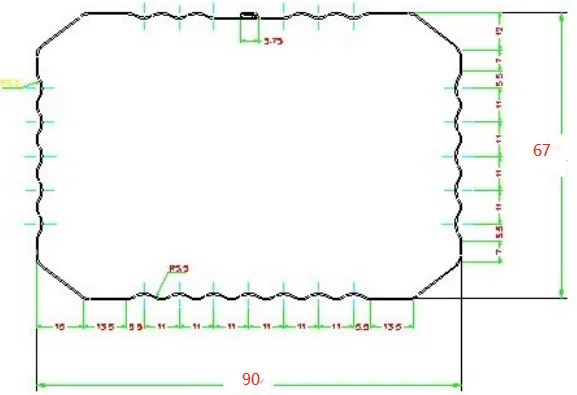

Drawings

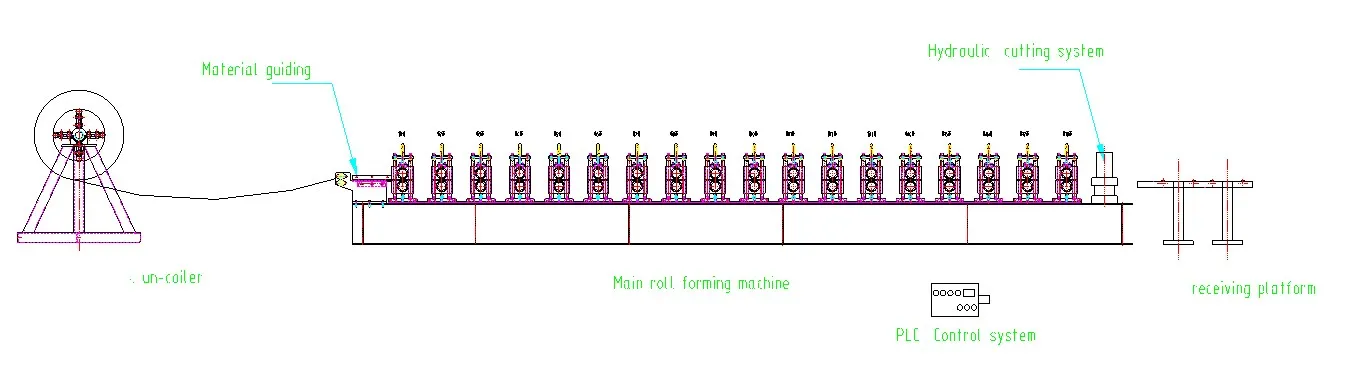

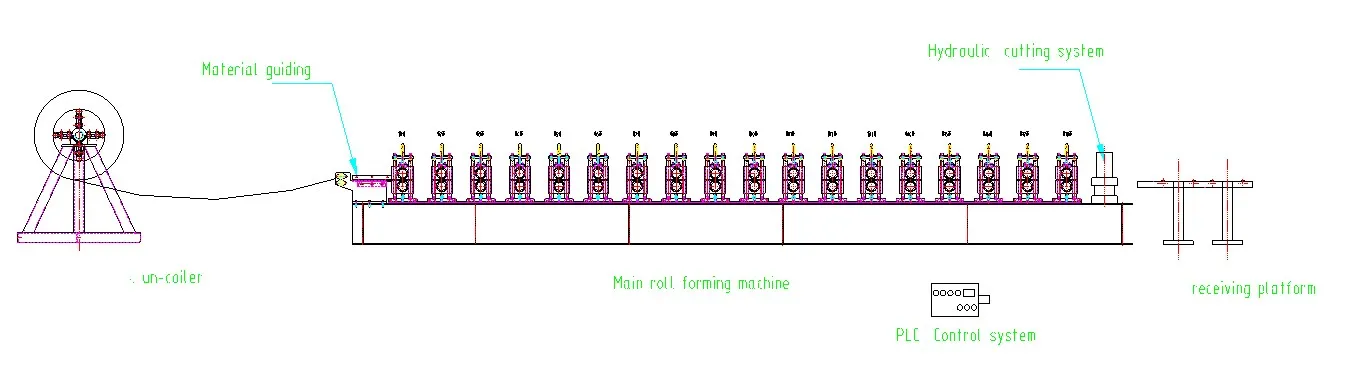

Working Process

Decoiler— material straightening and flattening— roll forming— plc control--- Flying saw cutting----receiving table

Component

| 3tonde-coiler |

x1 set |

| Main roll formingmachine |

x1 set |

| Flying cuttingsystem |

x1 set |

| Hydraulicstation |

x1 set |

| PLC Controlsystem |

x1 set |

| Collection table |

x1 set |

|

Manual decoiler

1.Max bear: 3 tons

2.Max width: 350mm

3.ID: 508

|

|

Straighten system

1.Width: 350mm

2.Drive: manual

|

|

|

Roll forming machine

Matching material: GI/PPGI/color steel/Al

Material thickness range:0.4-0.7mm

Main motor power:5.5kw

Forming speed: 8- 10m/min

Quantity of rollers: 21

Shaft Material and diameter: ¢70mm, material is 45#

7.Tolerance: 3m+- 1.5mm

Controlling system: PLC

Voltage: 380V/ 3phase/ 50 Hz

10.Material of forming rollers: 45# forge steel , coated with chromed treatment 11.Material of cutter blade: Cr12 mould steel with quenched treatment 58-62℃

12.Total weight: about 5Tons L*W*H 8m*1.0m*1.5m

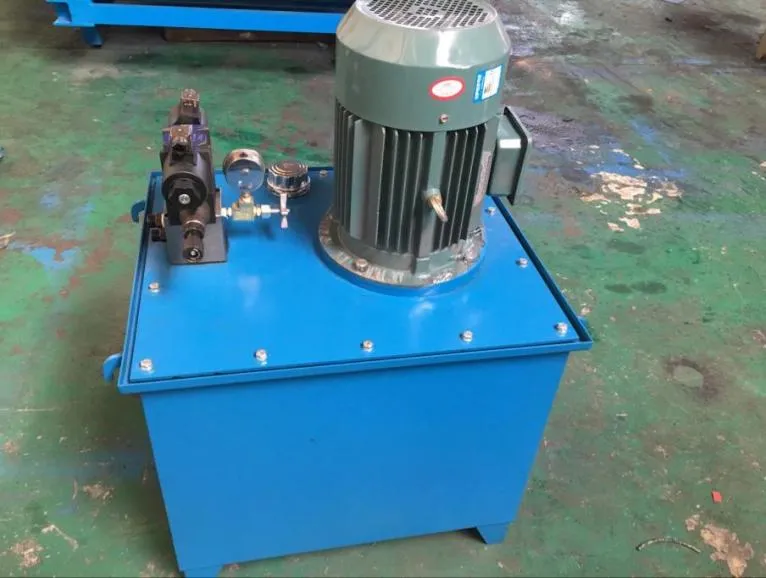

4.Hydraulic system

|

|

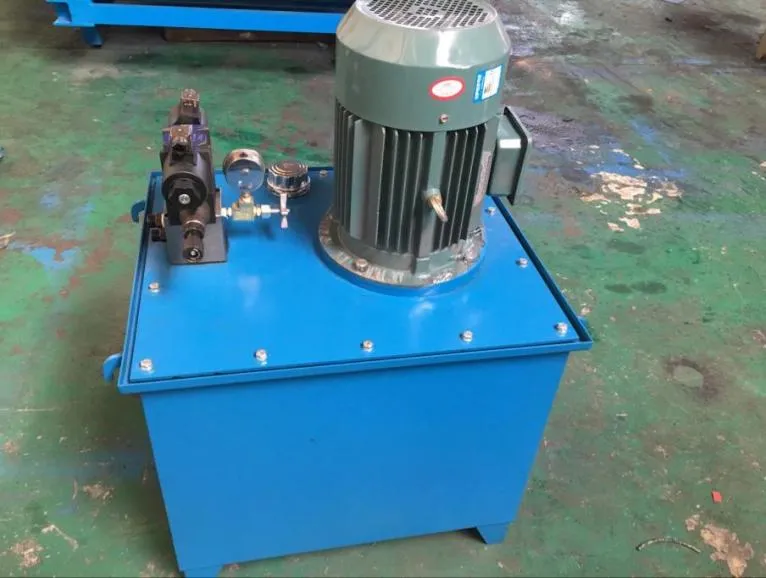

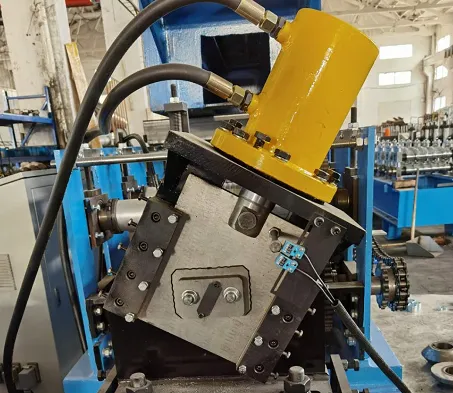

Hydraulic system

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

Match equipment :The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves.

|

|

|

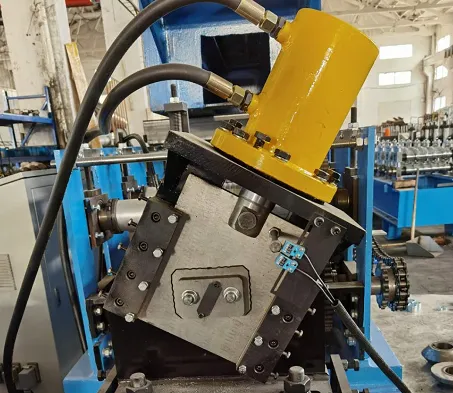

Hydraulic cutting

1.Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start. (Automatic tracking cutting)

2.Material of blade: GCR12with heat treatment

- Length measuring: Automatic length measuring

4.Tolerance of length: +/- 1.5m

|

|

Receving table

1.Sizeof receiving table: 2000mmx2 pieces

2.Material receiving platform structure: drum type structure, angle steel welding, no power

|

|

|

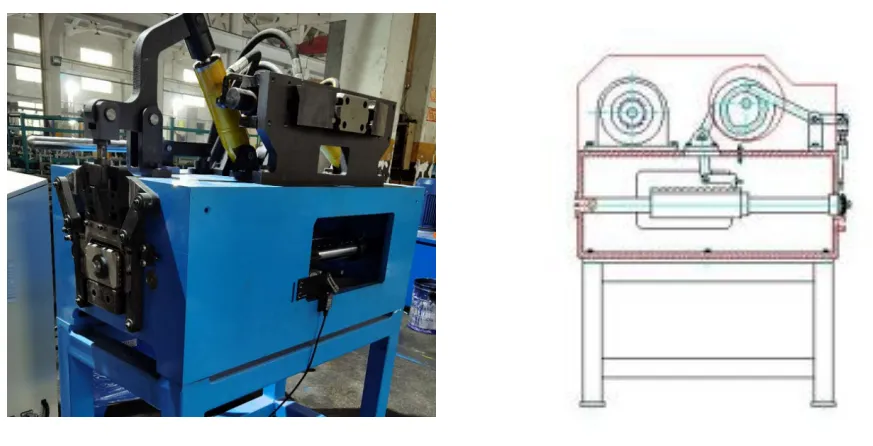

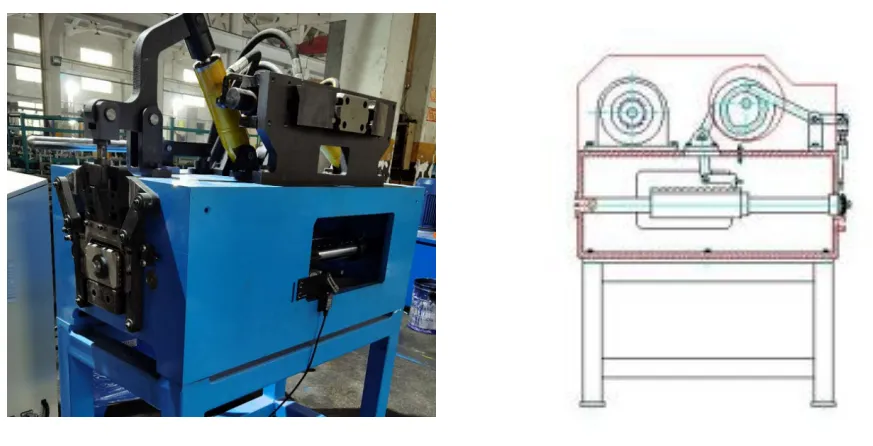

- Bender machine

- Body: 22 mm steel plate with welding

- motor power: 3 kw cycloid

- transmission way: double row of chain structure with (P, 25.4)

- Bender principle: the rack and mechanical drive way

- control box: 1 set

- Dimensions:1.2 * 1.5 * 1.5 m

|