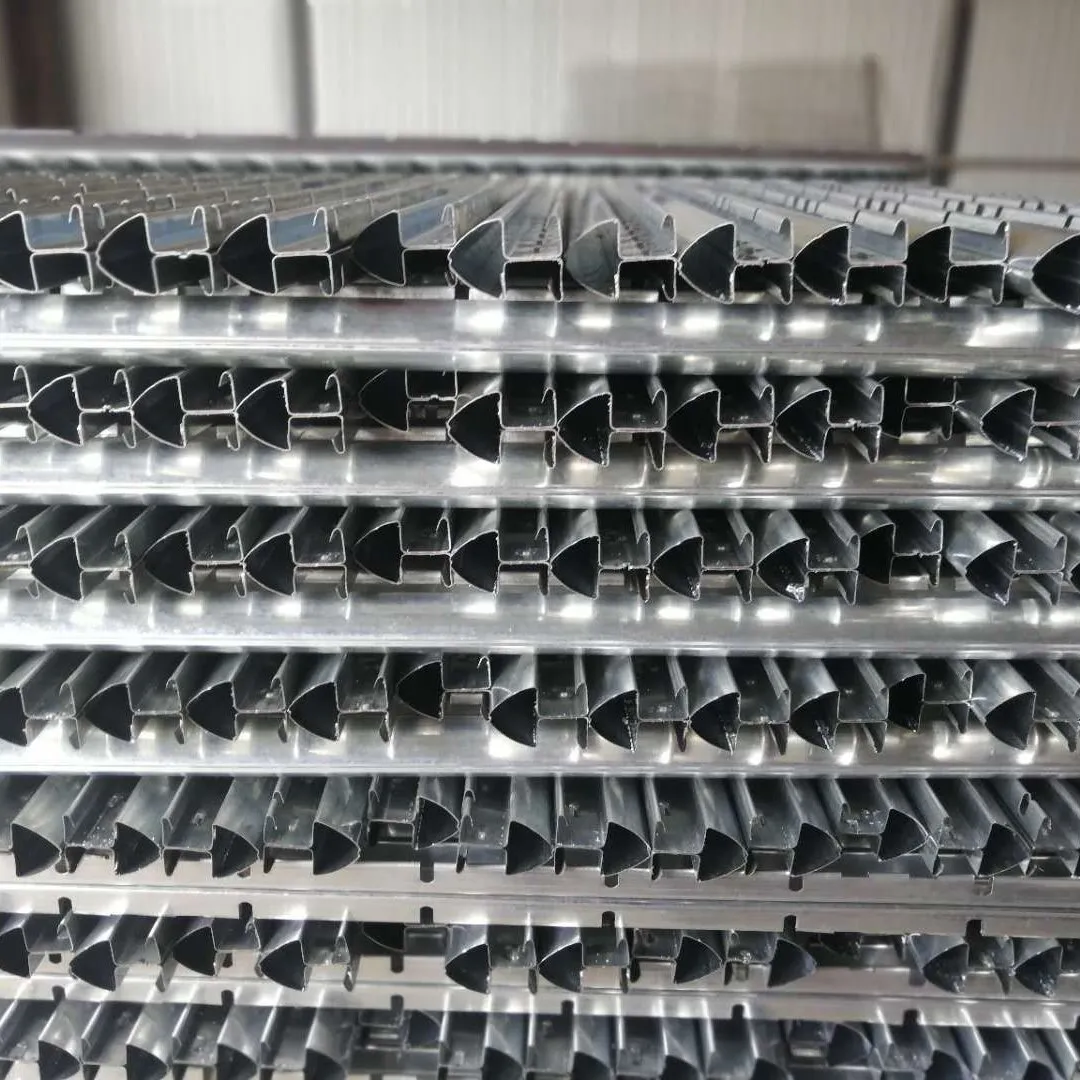

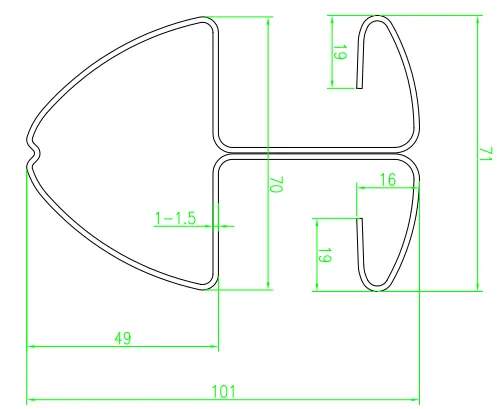

Drawings

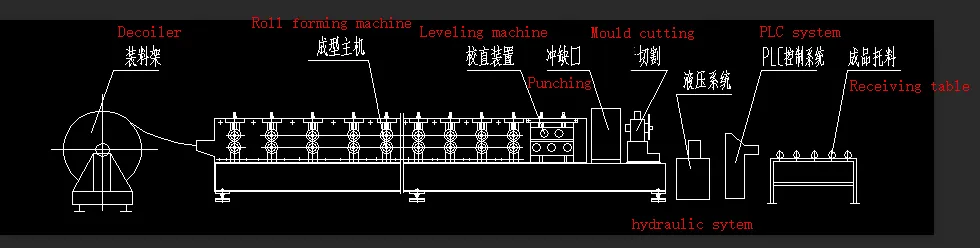

Processus et components

| De-coiler | x1 set |

| Pelagus volumine formatam machinam | x1 set |

| Pungendi ratio | x1 set |

| Systema HYDRAULICUS secantis | x1 set |

| HYDRAULICUS station | x1 set |

| PLC Control system | x1 set |

| Currere de mensa (3M * II) | x1 set |

Processus working

Technical parametri

|

Decoiler: |

1.ID of feeding Coil:φ508㎜,or φ610㎜ 2.Max latitudine D㎜ 3.Max pondus 5T 4.Material:Aluminum and zinc plate galvanized plate color steel plate low carbon steel |

|

Sepe recto volumine faciunt machinam |

1. Matching material: colored armor plate with the bending intensity of Q195-235 .Material thickness: 1.2mm 2. Power: 11kw hydraulic station power:5.5kw 3. Formans celeritatem: 10-15 m/min 4. Latitudo laminarum: 360mm 6. Stationes Roll: 25 7. Shaft Material and diameter: material is 45#, ¢80mm (the material hardness is better than 45# steel) 8. Tolerantia: +-1.5mm 9. Viam coegi: catenam 10. Controlling system: PLC 11. Voltage: 220v ,60hz ,3ph ( as customer require) 12. Materia faciendi scutulis: Gcr15 13 Material of cutter blade: Cr 12 mould steel with quenched treatment HRC58-62 |

|

Secare |

1.Cutting motus: Machina principalis automatice subsistit ac deinde inciditur. Post sectionem, machina principalis statim incipiet. 2.Material of ferrum: GCR12 cum calor curatio 3.Length mensuræ: Lorem longitudinem mensurae 4.Tolerance longitudinis: 10+/- 1.5mm |

|

PLC imperium systema

|

1. Voltage, Frequency, Phase: 380 V, 60 Hz, 3Phase (this is can depend on customer request) 2. Lorem longitudinem mensurae; 3. Lorem quantitas mensurae 4. Computer longitudinem & quantitatem regere solebant. Machina sponte secare ad longitudinem et desine cum requiritur quantitas fit 5. Longitudo indiligentia facile emendari potest 6. Imperium panel: Button-type switch and touch screen 7. Unitas longitudinis: millimeter (switched on the control panel) |

|

Color machinae |

Blue (placere referat ad confirmandam color) |