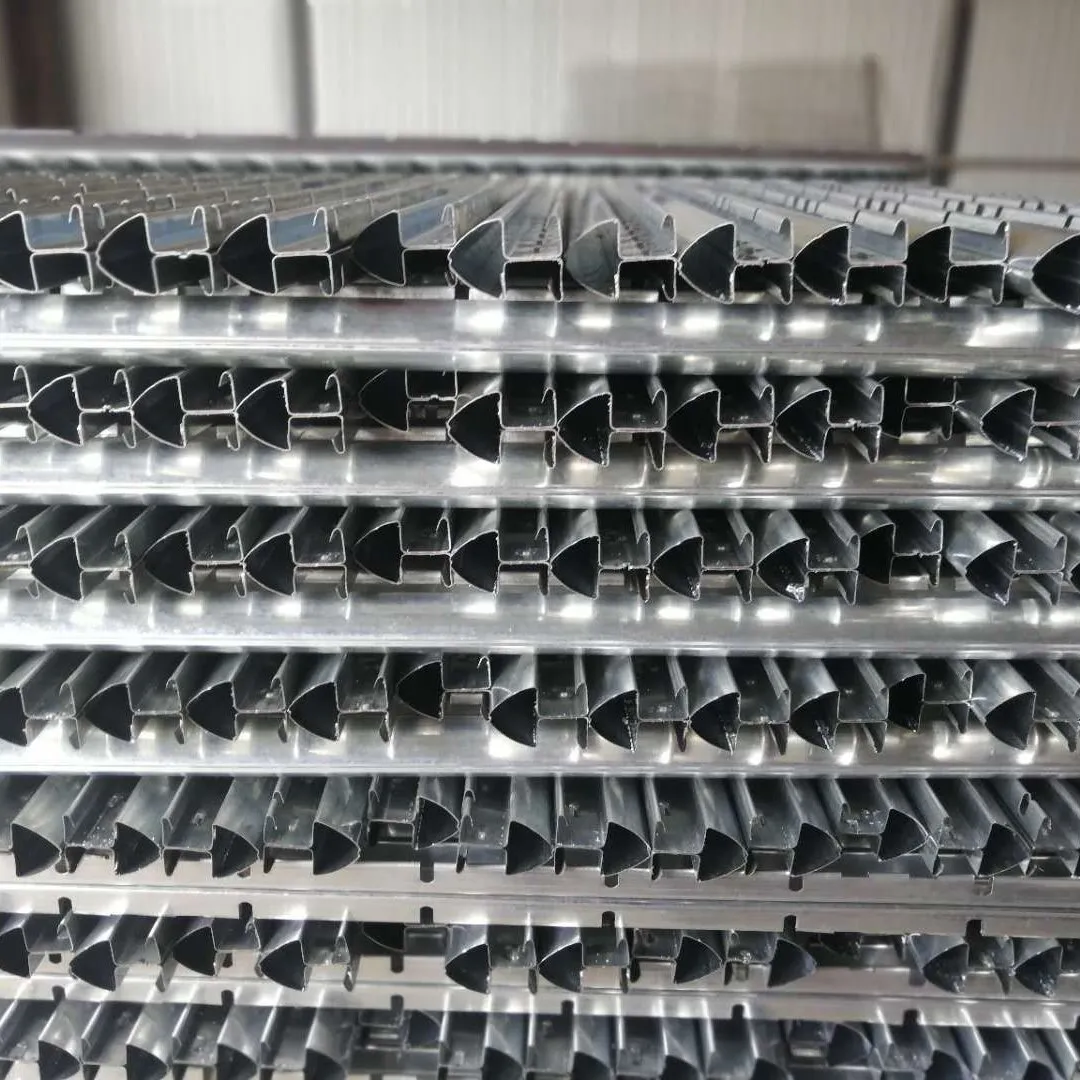

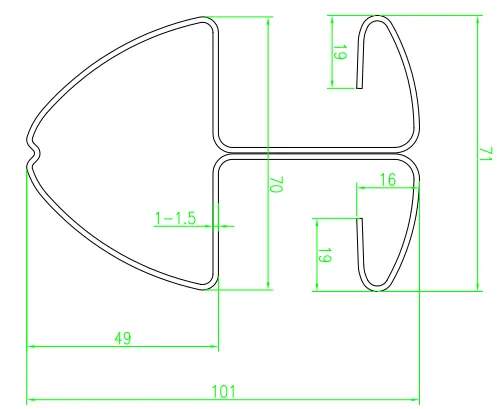

Drawings

Processes and components

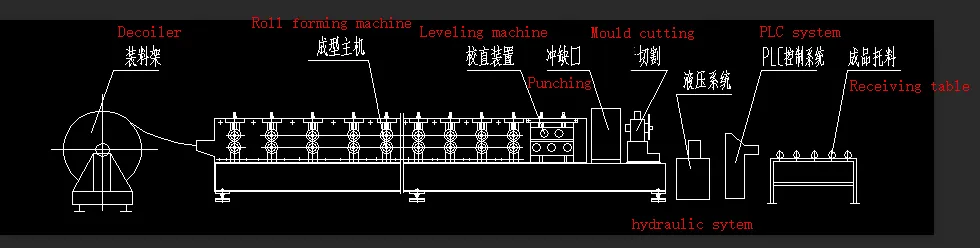

| De-coiler | x1 set |

| Main roll forming machine | x1 set |

| Punching system | x1 set |

| Hydraulic cutting system | x1 set |

| Hydraulic station | x1 set |

| PLC Control system | x1 set |

| Run-out table (3M*2) | x1 set |

Working Process

Technical parameters

|

Decoiler : |

1.ID of feeding Coil:φ508㎜,or φ610㎜ 2.Max width:500㎜ 3.Max weight :5T 4.Material:Aluminum and zinc plate galvanized plate color steel plate low carbon steel |

|

Fence upright roll forming machine |

1. Matching material: colored armor plate with the bending intensity of Q195-235 .Material thickness: 1.2mm 2. Power: 11kw hydraulic station power:5.5kw 3. Forming speed: 10-15 m/min 4. The width of the plates:360mm 6. Roll stations: 25 7. Shaft Material and diameter: material is 45#, ¢80mm (the material hardness is better than 45# steel) 8. Tolerance: +-1.5mm 9. Way of drive: chain 10. Controlling system: PLC 11. Voltage: 220v ,60hz ,3ph ( as customer require) 12. Material of forming rollers:Gcr15 13 Material of cutter blade: Cr 12 mould steel with quenched treatment HRC58-62 |

|

Cutting |

1.Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start. 2.Material of blade: GCR12 with heat treatment 3.Length measuring: Automatic length measuring 4.Tolerance of length: 10+/- 1.5mm |

|

PLC control system

|

1. Voltage, Frequency, Phase: 380 V, 60 Hz, 3Phase (this is can depend on customer request) 2. Automatic length measurement: 3. Automatic quantity measurement 4. Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved 5. Length inaccuracy can be amended easily 6. Control panel: Button-type switch and touch screen 7. Unit of length: millimeter (switched on the control panel) |

|

Color of the machine |

Blue(please reference the color for confirming) |