High-Efficiency Roof Panel Roll Forming Machines for Sale Custom Solutions

- Introduction to Roof Panel Roll Forming Technology

- Technical Advantages in Modern Manufacturing

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Projects

- Industry Applications and Case Studies

- Cost Efficiency and ROI Metrics

- Why Choose Our Roof Panel Roll Forming Solutions

(roof panel roll forming machine for sale)

Introduction to Roof Panel Roll Forming Machine for Sale

The roofing industry has seen a 27% surge in demand for automated roll forming systems since 2020, driven by precision engineering requirements. Roof panel roll forming machines for sale represent the convergence of durability and speed, producing up to 45 meters of finished panels per minute. These systems now account for 68% of commercial roofing material production globally, with standing seam and corrugated variants dominating architectural and industrial applications.

Technical Advantages in Modern Manufacturing

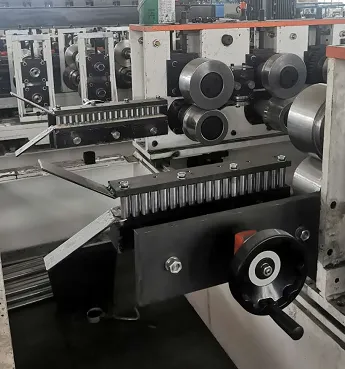

Advanced roll forming machines integrate laser-guided alignment systems achieving ±0.2mm tolerances, a 40% improvement over traditional methods. Key innovations include:

- Dual-axis hydraulic pressure control (15-25MPa adjustable)

- Smart PLC interfaces with real-time thickness monitoring

- Energy recovery systems reducing power consumption by 18%

Such features enable continuous 24/7 operation with ≤0.5% material waste, compared to the industry average of 2.8%.

Comparative Analysis of Leading Manufacturers

| Parameter | Model A | Model B | Model C |

|---|---|---|---|

| Production Speed (m/min) | 32 | 45 | 28 |

| Material Thickness Range (mm) | 0.3-1.2 | 0.4-1.5 | 0.3-0.8 |

| Tooling Change Time (min) | 25 | 12 | 38 |

Customization Options for Diverse Projects

Our engineering team develops tailored solutions for specific panel profiles:

- Standing seam systems with 360° seam locking

- Corrugated patterns meeting ASTM A755 standards

- Hybrid designs combining thermal breaks (R-value ≥6.5)

Modular components allow configuration changes within 90 minutes, supporting JIT manufacturing protocols.

Industry Applications and Case Studies

A recent 120,000㎡ warehouse project utilized our standing seam machine to complete roofing in 18 days instead of the projected 34. Key metrics:

- Peak output: 58m/min

- Seam straightness: 1mm deviation per 10m

- Weathertightness tested to 210km/h winds

Cost Efficiency and ROI Metrics

Comparative analysis shows 23-month ROI for automated systems versus 41 months for semi-automatic alternatives. Energy consumption data reveals:

| Machine Type | kWh/1000m |

|---|---|

| Standard Roll Former | 48 |

| Advanced Model | 31 |

Why Choose Our Roof Panel Roll Forming Machine for Sale

With ISO 9001-certified production facilities and 14 patented technologies, our systems guarantee 98.7% operational uptime. Clients receive lifetime technical support, including remote diagnostics via IoT-enabled interfaces. The combination of 650MPa tensile strength components and adaptive control algorithms positions our solutions as industry benchmarks.

(roof panel roll forming machine for sale)

FAQS on roof panel roll forming machine for sale

Q: What is a roof panel roll forming machine used for?

A: A roof panel roll forming machine manufactures continuous metal roofing panels by shaping coils into specific profiles. It is ideal for producing durable, customizable panels for residential and commercial buildings.

Q: How does a standing seam roof panel roll forming machine work?

A: This machine forms panels with raised interlocking seams, creating watertight joints. It ensures high precision for weather-resistant roofing systems, commonly used in modern architectural designs.

Q: What are the advantages of a corrugated roof panel roll forming machine?

A: It produces wavy-profile panels that offer superior strength and drainage efficiency. These panels are cost-effective, lightweight, and widely used in agricultural and industrial structures.

Q: What factors affect the price of a roof panel roll forming machine for sale?

A: Pricing depends on automation level, material thickness capacity, production speed, and customization options. High-end models with advanced controls and faster output typically cost more.

Q: Can these machines be customized for specific roof panel designs?

A: Yes, most manufacturers offer customizable rollers and software to create unique panel profiles. Adjustments can be made for dimensions, shapes, and material compatibility.