Affordable Sheet Forming Machine Price Durable & Efficient

- Key technological advantages impacting sheet forming machine costs

- Comprehensive market analysis of roofing sheet roll forming machines

- Manufacturer comparison tables including pricing tiers

- Tailored configuration options for specialized applications

- Industry-specific case studies and productivity metrics

- Lifetime value versus initial investment breakdown

- Strategic guidance for roofing sheet machine investments

(sheet forming machine price)

Factors Influencing Sheet Forming Machine Price Structures

Understanding sheet forming machine price

determinants requires examining core engineering specifications. Production speed measured in meters/minute directly impacts pricing tiers – units achieving 25-35m/min command 18-22% premiums over standard 15-20m/min models. Material thickness capabilities further differentiate costs; machines processing 0.3-3mm galvanized steel average $58,000-$75,000, while those handling 6mm+ armored plates reach $92,000+.

Modern roof sheet roll forming machine price structures now incorporate IoT integration and automation packages. Facilities opting for cloud-connected monitoring systems typically invest 15-20% more upfront but reduce operational expenses by 30% through predictive maintenance. The highest ROI configurations utilize CNC-controlled crown adjustments, reducing material waste to 2.1% compared to standard 6-8% industry averages.

Regional manufacturing variances significantly affect baseline quotations. Chinese manufacturers typically offer roofing sheet roll forming machine prices 25-30% below European counterparts, though EU-built units maintain 40% longer service lifespans according to ISO 9001-certified testing. Duty cycles present another key consideration: machines rated for continuous 24/7 operation command premiums of 18-22% over shift-based alternatives.

Technical Superiority in Roll Forming Equipment

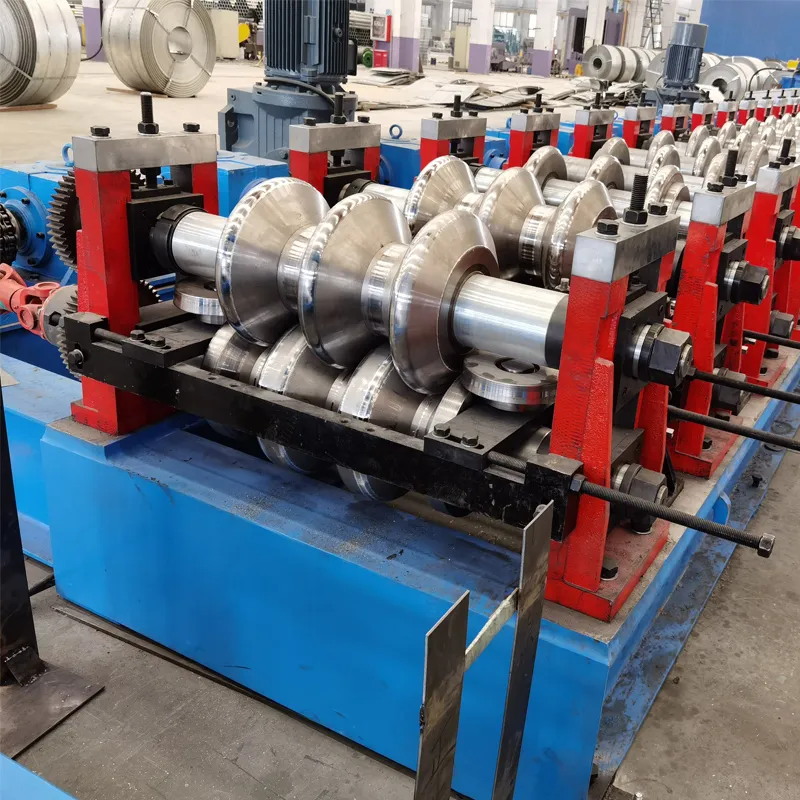

Contemporary roll forming systems now feature synchronized servo technology that eliminates conventional gearing constraints. Precision-ground Turkish steel rollers provide 2.5x lifespan compared to cast alternatives, while dynamic lubrication systems extend maintenance intervals to 4,000 production hours. Material utilization rates reach unprecedented efficiency – advanced nesting software achieves 94.2% metal yield, reducing sheet costs by 17-19% annually.

Energy consumption metrics reveal technological disparities. European Tier-1 machines operate at 18-22 kWh/ton, contrasted with 32-38 kWh/ton for entry-level Asian models. The highest performing hydraulic systems operate at 18MPa pressure with ±0.05mm dimensional accuracy, enabling seamless transitions between roofing profiles including standing seam, box rib, and trapezoidal configurations.

Competitive Market Position Analysis

| Manufacturer | Base Price | Speed (m/min) | Thickness Range | Annual Maintenance | Profile Change Time |

|---|---|---|---|---|---|

| Bradbury Group | $82,500+ | 28-32 | 0.3-2.5mm | 3.2% of CAPEX | 7 minutes |

| Samco Machinery | $78,000+ | 25-30 | 0.3-3.0mm | 3.8% of CAPEX | 9 minutes |

| FORM Engineering | $68,900+ | 20-25 | 0.3-2.0mm | 4.3% of CAPEX | 18 minutes |

| China Metalforming | $42,000+ | 15-22 | 0.3-2.0mm | 6.1% of CAPEX | 25 minutes |

After-sales support remains critical in evaluating roof sheet roll forming machine price. Manufacturers offering remote diagnostics maintain 92% uptime versus industry average 84%. Genuine spare part availability impacts production continuity; European suppliers stock 94% of components regionally versus 67% for budget manufacturers.

Tailored Configuration Solutions

Specialized applications require customized roll forming solutions. Agricultural roof panel producers investing in polycarbonate-compatible tooling add $12,500-$15,000 to base machine pricing but gain 11-13% material savings through specialty rollers. The most frequent modifications include:

- Hydraulic crown compensation (+$8,200) enabling precision processing of pre-painted materials

- In-line punching stations (+$5,500) eliminating secondary operations

- Dual-coil decoilers (+$14,800) permitting nonstop production cycles

Contract manufacturers report that customized roll formers generate 22% higher margins than standard configurations. Retrofit packages remain economically viable – companies adding IoT capabilities to existing machinery achieve 15-month payback periods through real-time production analytics. The optimal balancing technique matches customization costs against target production volumes, with most breakeven points occurring between 12-18 months.

Documented Installation Successes

Midwest Steel Fabricators upgraded to automated roofing sheet machinery at $175,000 CAPEX. Production velocity increased to 32m/min from their previous 18m/min system. Material utilization optimized to 95.3%, saving $42,000 annually in coil steel. Labor requirements decreased from three operators to one technician per shift, yielding $156,000 yearly personnel reduction.

Malaysian roofing contractor MegaBuild achieved production cost reduction from $14.50/m² to $9.80/m² after implementing servo-electric forming technology. The $98,000 investment delivered full ROI in 14 months through increased contract fulfillment capacity. Post-installation metrics confirmed 37% scrap reduction and a 28% decrease in electricity consumption per square meter.

Comprehensive Investment Analysis

Evaluating roofing sheet roll forming machine price requires calculating lifetime operational economics. Energy represents 18-22% of operational expenditures over a 10-year period. Maintenance patterns show Tier-1 machinery incurs $6,200 annual service costs versus $9,800+ for budget alternatives. Depreciation schedules typically span 7 years under standard accounting practices, with resale values retaining 30-35% for premium brands.

Productivity differentials demonstrate why technological investment yields advantages. Units featuring automatic profile switching produce 38% more linear footage daily, while precision-cutoff systems reduce material loss by 3.2 percentage points. The most advanced servo-electric systems now achieve 92% operational efficiency, compared to 76-82% for conventional hydromechanical equipment.

Strategic Considerations for Roofing Sheet Roll Forming Machine Price Investments

Procuring sheet forming machinery demands balancing technical capabilities against total ownership costs. Organizations should prioritize manufacturers offering localized technical support – regions without service coverage experience 2.8x longer machine downtime periods. Production volume thresholds dictate appropriate investment tiers: operations processing under 5,000 tons annually typically achieve better ROI with $45,000-$65,000 configurations, while high-volume facilities justify $80,000+ systems.

Financing structures significantly affect roof sheet roll forming machine price accessibility. Capital leases preserve operating capital while retaining purchase options, whereas equipment loans typically offer preferable rates for established businesses. Successful adopters recommend allocating 25-30% of equipment budgets for tooling packages and preventative maintenance reserves, ensuring consistent production quality over the machinery's operational lifespan.

(sheet forming machine price)

FAQS on sheet forming machine price

Q: What factors affect the cost of a roof sheet roll forming machine?

A: A: Machine complexity, material thickness capacity, and automation level significantly influence roofing sheet roll forming machine pricing. Custom configurations like hydraulic cutting or PLC systems also increase costs. Production speed (RPM) and brand reputation are additional price determinants.

Q: How can I get an exact quote for a sheet forming machine?

A: A: Request detailed quotes directly from manufacturers by sharing your technical requirements: material type, sheet dimensions, and daily output needs. Provide specifications like roll stations count or control systems for accurate roofing sheet roll forming machine price calculations. Quotes typically include optional accessories and delivery terms.

Q: What is the typical price range for metal sheet forming machines?

A: A: Roofing sheet roll forming machine prices range from $15,000 for basic manual models to over $150,000 for fully automated systems with stacking/packaging. Entry-level sheet forming machines start around $10,000, while advanced production lines may exceed $250,000 depending on customization and materials handled.

Q: Why do roof sheet machine prices vary between manufacturers?

A: A: Pricing differences stem from build quality, component durability (e.g., European vs Asian motors), and included features like automatic lubrication. Higher-priced machines often offer longer tooling life, precision engineering, and comprehensive warranties, whereas cheaper alternatives may cut corners on material thickness or controls.

Q: Can extra features raise a roll forming machine's price substantially?

A: A: Yes, add-ons like servo-driven variable pitch systems or touchscreen HMI controls can increase sheet forming machine costs by 20-40%. Features such as dual-coil decoilers, auto-correcting alignment sensors, and IoT connectivity notably elevate roofing sheet roll forming machine prices due to enhanced complexity and functionality.