|

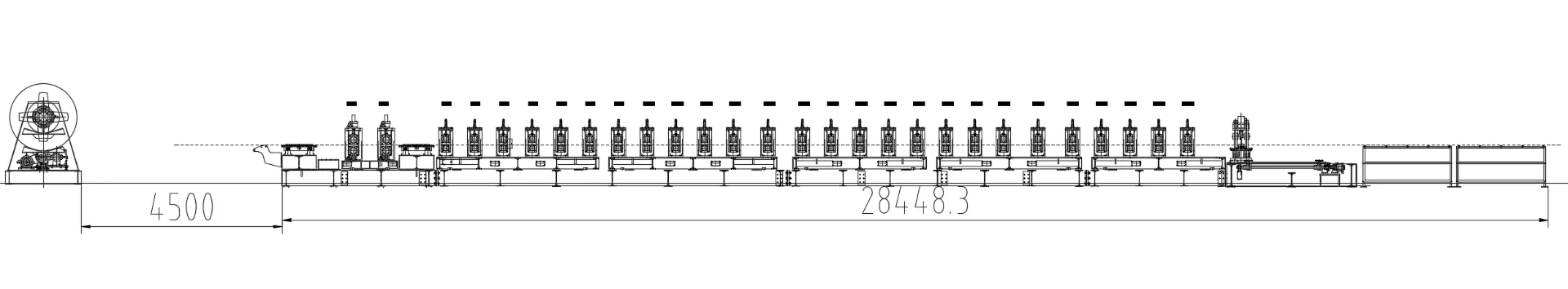

3.Roll forming machine

(1).The way of guiding and feeding :Adjustable side handwheel

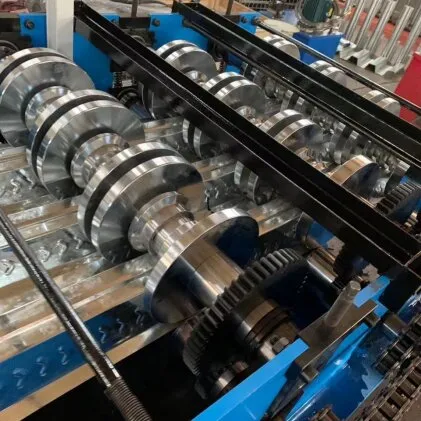

(2).The frame of roll forming machine:Cast iron memorial archway with gear box

(3).The frame :Steel welding

(4).Shaft diameter:Φ90

(5).The forming machine motor power:2x15KW

(6). Forming speed:0-20m/min

(7).Roll station : 25stations

(8).The metrial of rollers :40Cr quenching and tempering treatment(HB220-260)

(9).Roller surface treatment:Hard chromium plating

(10).shearing structure: Torri stand

(11).Gear box:180

(12).Motor power: 5.5KW

(13).Shear blade material: Cr12MOV

(14).Shear blade heat treatment hardness: HRC58-62

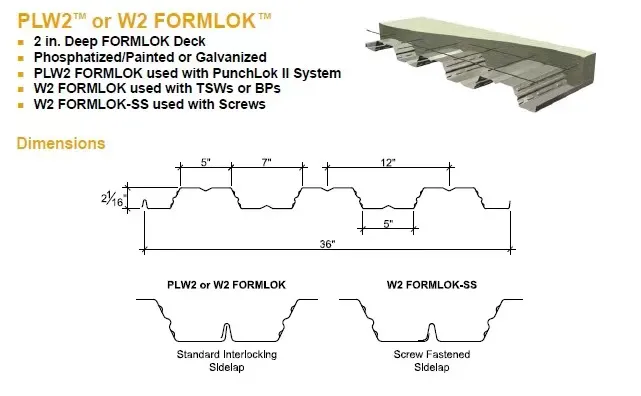

(15).Rolling thickness:0.6-1.5mm

(16).Unfold size:1250mm

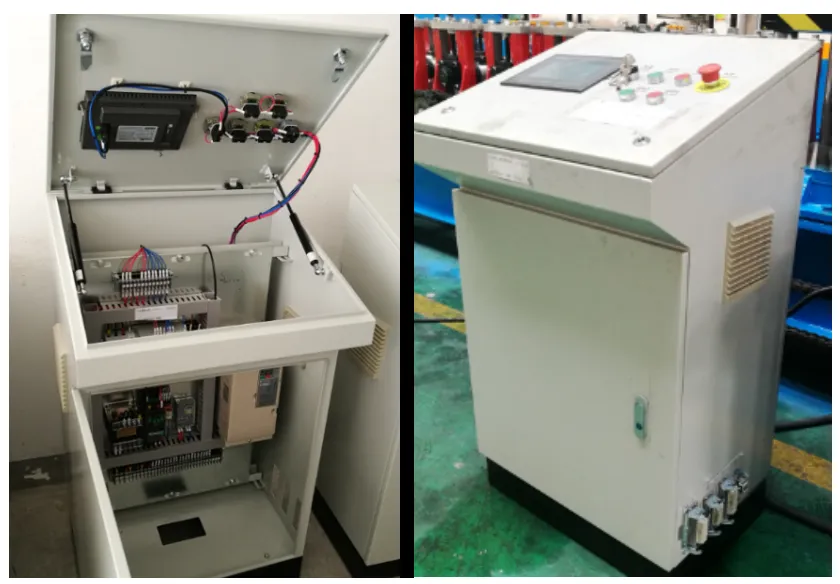

(17).length error: + 1.0mm

(18).Yaskawa inverter: (Japan)

(19).the computer uses PLC control:Delta

(20).Computer operation panel: Delta

|