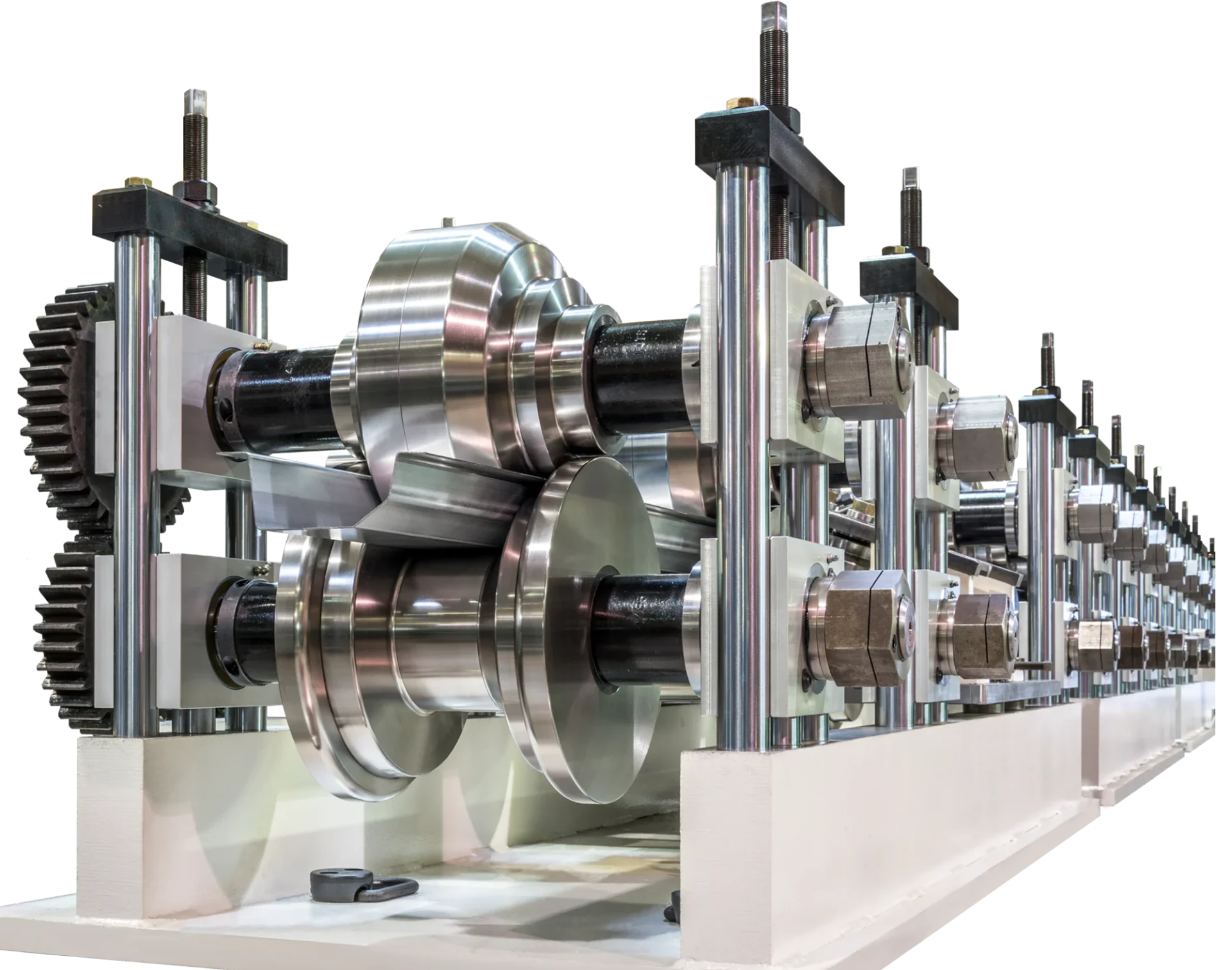

The Cold Roll Forming Machine is a vital component in the production of various metal profiles. It utilizes a series of rollers to shape metal sheets into desired cross-sectional forms, ensuring high accuracy and consistency.

The Slitting Line & Cut to Length Line is designed for processing metal coils. The slitting line cuts wide coils into narrower strips, while the cut to length line further processes these strips into specific lengths.

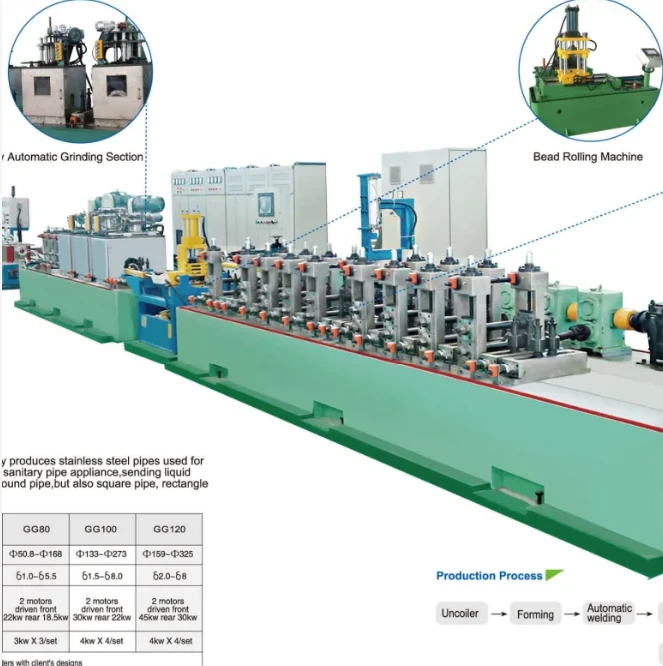

The Tube Mill is another critical machine that specializes in the production of tubular products. It forms flat metal strips into tubes through a series of welding and shaping processes.

The Sandwich Panel Production Line offers an innovative solution. This line produces composite panels consisting of two outer layers and an insulating core, ideal for energy-efficient building applications.

The Decoiler serves as the starting point in the production process. It unwinds metal coils, ensuring a smooth and continuous feed into subsequent machinery.

The PVC roll forming machine is designed to produce high-quality PVC profiles with precision and speed. This machine utilizes advanced technology to transform PVC sheets into various shapes and sizes, catering to the needs of construction, automotive, and furniture industries.

The H beam welding and straightening machine is specifically engineered for the fabrication of H beams, which are widely used in structural applications.

The wire mesh welding machine is essential for producing high-strength wire mesh used in construction, fencing, and various industrial applications.