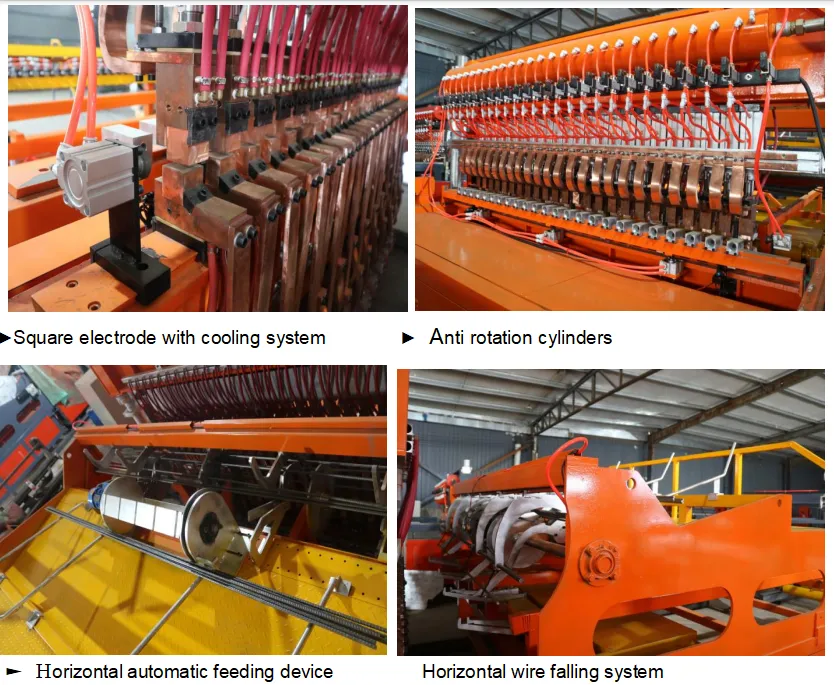

Product Display

Component

|

Welding machine |

1 set |

|

Wire carrying car |

1 set |

|

Precut wire feeder |

1 set |

|

Air compressor |

1 set |

|

Chiller |

1 set |

|

Receiving table (3M * 2.5M*1M) |

1 set |

Machine instruction

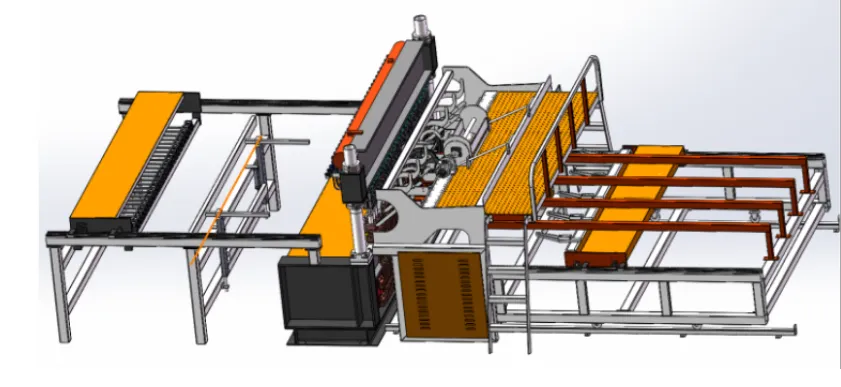

1.The machine adopts pneumatic wire clamping and servo motor wire feeding, which can accurately deliver the iron wire to the designated position.

2.The welding electrode is made of pure copper .it’s square size(50*50*50mm).

3.The machine is equipped with a horizontal automatic feeding device, which can accommodate 1T.

4.The machine adopts pneumatic welding method, and we use anti rotation cylinders to determine the stability of welding part.

5.There are water cooling system with electrode and transformers.Using a water circulation system to reduce the heat generated by welding and increase its service life.

6.The machine is equipped with a horizontal wire detection system. If the horizontal wire does not fall to the designated position, the machine will automatically stop to avoid welding leakage and ensure quality.

7.The mesh pulling system is controlled by CNC system. High accuracy.and easy to adjust.

8.Fully automatic aggregate system, reducing manual operation and saving energy.

Parameters and specification

|

Model |

YW- 2500 |

|

|

Wire diameter |

5-12mm |

|

|

Line wire space |

100-300mm |

|

|

Cross wire space |

100-200mm |

|

|

Mesh width |

Max.2500mm |

|

|

Mesh length |

Max. 10m in Panel |

|

|

Welding electrodes |

26pcs |

|

|

Welding speed |

80-100 times/min |

|

|

Welding transformers |

200kva*13pcs |

|

|

Welding method |

Pneumatic welding |

|

|

Horizontal wire feeding |

Pre-straightened & pre-cut |

|

|

Vertical Wire feeding |

Pre-straightened & pre-cut |

|

|

Machine size & weight |

6.9*3.4*2.2m 6.5T |

|

|

Raw material |

rolled ribbed steel/ low carbon steel / |

|

|

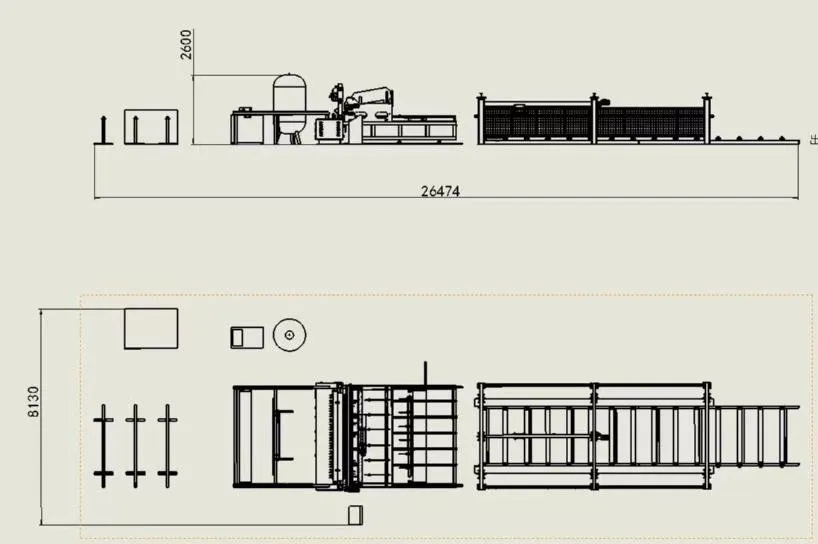

Installation tips:

1. The required power supply at least 300KVA, bigger and better. 2. The distance between main welding machine and power supply must be less than100m. 3. Layout space at least 35*15m 4. Cable size: copper cable 125MM2 / phase. |

||

Wire mesh welding machines are utilized across various industries, including:

1.Construction: For creating reinforcement mesh used in concrete structures.

2.Agriculture: To produce fencing and enclosures for livestock and crops.

3.Manufacturing: In the production of wire mesh products for filtration, security, and other applications.

4.Mining and Quarrying: For creating protective barriers and support structures.

Machine pictures