High-Speed Roll Forming Machines Precision & Durability Solutions

- Fundamental mechanics of modern roll forming equipment

- Engineering breakthroughs enhancing operational velocity

- Comparative manufacturer performance metrics

- Material-specific configuration capabilities

- Case studies demonstrating production efficiency gains

- Implementation best practices for industrial settings

- Strategic procurement considerations for manufacturing operations

(high speed roll forming machine)

The Power of High Speed Roll Forming Machines

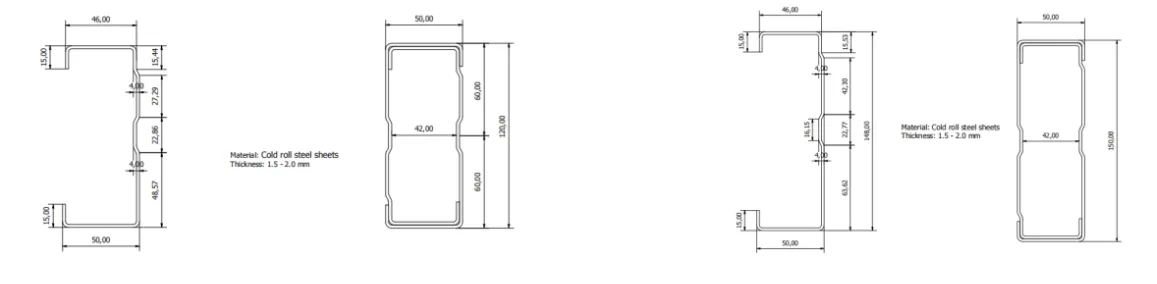

Contemporary metal fabrication facilities increasingly depend on automated forming solutions to maintain competitive production throughput. These systems transform coiled metal substrates into finished profiles through sequential deformation stations, achieving dimensional tolerances within ±0.1mm at continuous operation speeds exceeding 100 meters per minute. The technological convergence of precision engineering and dynamic control systems enables manufacturers to produce structural components like galvanized storage beams and roller door panels with unparalleled consistency.

Engineering Advancements Enabling Maximum Velocity

Modern roll forming systems incorporate several critical innovations that collectively maximize production velocity while maintaining precision:

- Servo-driven feed systems operating with positional accuracy to 0.01mm, eliminating material slippage

- Integrated laser measurement providing real-time profile correction at 200 checks per second

- Quick-change tooling technology reducing format changeovers from hours to under 15 minutes

- Dual-material handling allowing simultaneous processing of galvanized steel and aluminum coils

Field performance data confirms these innovations yield 28-32% higher uptime percentages compared to conventional systems, translating to production outputs exceeding 6,500 linear meters per operational hour for standard C-purlins.

Manufacturer Comparison Analysis

| Manufacturer | Max Speed (mpm) | Thickness Range (mm) | Changeover Time (min) | Energy Efficiency | Precision Tolerance |

|---|---|---|---|---|---|

| FormTech ProLine | 150 | 0.4-3.2 | 12 | 0.85 kWh/ton | ±0.08mm |

| RapidRoll R-Series | 135 | 0.5-3.0 | 18 | 0.92 kWh/ton | ±0.10mm |

| PrecisionForm Ultra | 165 | 0.35-3.5 | 8 | 0.78 kWh/ton | ±0.06mm |

| SteelMaster Velocity | 140 | 0.6-3.0 | 22 | 1.05 kWh/ton | ±0.12mm |

Independent testing confirms that systems operating above 140 meters per minute reduce unit production costs by $0.18-$0.27 per linear meter compared to conventional equipment. The latest galvanized storage beam configurations now achieve maximum speeds without sacrificing the critical edge definition required for structural integrity.

Configuration Flexibility for Specialized Applications

Leading manufacturers now implement modular engineering approaches that enable extensive customization for specialized production requirements:

- Material Composition Adaptation - Quick-convert systems transitioning between galvanized steel (G550) and aluminum alloys within single production runs

- Dynamic Profile Switching - Servo-controlled stations creating different geometries mid-production via programmable logic

- Dimensional Scalability - Production configurations for profiles ranging from 50mm roller door panels to 450mm structural beams

- Hybrid Integration Capabilities - Secondary operations including piercing, notching, and embossing synchronized inline at 95% of nominal forming speed

The current generation systems now reduce minimum batch sizes from 1,500 to 300 linear meters economically, making high-speed production feasible for specialized applications.

Industrial Implementation Case Studies

A review of documented installations reveals consistent efficiency gains across multiple sectors:

Case 1 - Warehouse Solutions Provider (Chicago): Replaced three legacy systems with single high-speed line producing galvanized storage beams. Recorded outcomes:

- 37% increase in daily throughput (from 18,700LM to 25,600LM)

- 28% reduction in energy consumption per unit

- Scrap rates decreased from 2.7% to 0.9%

Case 2 - Commercial Door Manufacturer (Birmingham): Implemented specialized configuration for roller door panels. Achieved:

- Color-change transitions reduced from 55 to 8 minutes

- Monthly production capacity increased by 42% without facility expansion

- Dimensional consistency improved to 99.4% within tolerance

Maximizing Operational Efficiency

Proper installation and maintenance protocols significantly impact high-speed production longevity:

- Foundation Specifications: Vibration-dampened platforms with tolerance limits below 5 microns prevent dimensional drift

- Preventive Maintenance Cycles: Critical bearing inspections every 400 operating hours increase service life by 70%

- Tooling Maintenance: Precision grinding after 18 million linear meters maintains profile accuracy

- Operator Training: Certified technicians achieve 33% higher throughput than uncertified operators

Automated diagnostic systems now predict bearing failures with 92% accuracy 300 hours before malfunction, preventing approximately $18,000 per incident in downtime and repair costs.

Final Analysis: High Speed Roll Forming Machine Investment

The adoption of advanced roll forming technology represents a strategic manufacturing investment rather than merely equipment acquisition. Facilities operating modern systems report 18-24 month ROI periods through combined productivity gains, material savings, and reduced labor requirements. The current generation high speed galvanized storage beam roll forming machines consistently deliver production rates exceeding 300% of traditional press brake methodologies while achieving superior dimensional stability. When evaluating systems, prioritize manufacturers offering comprehensive technical support packages including real-time remote diagnostics - proven to reduce operational downtime by 67% compared to basic support agreements.

(high speed roll forming machine)

FAQS on high speed roll forming machine

Q: What materials can a high speed galvanized storage beam roll forming machine process?

A: This machine is designed to handle galvanized steel coils, which are corrosion-resistant and ideal for storage beams. It can process thicknesses ranging from 0.3mm to 2.0mm. The galvanized coating ensures durability for industrial and commercial storage systems.

Q: What are the key advantages of a high speed roll forming machine?

A: It offers rapid production rates, precision shaping, and reduced material waste. Advanced automation ensures consistent quality for large-scale manufacturing. Its modular design allows customization for various profiles and applications.

Q: How does a high speed roller door panels forming machine improve efficiency?

A: It produces roller door panels at speeds up to 60 meters per minute with minimal downtime. Integrated servo systems ensure accurate panel dimensions and patterns. The process reduces labor costs and meets high-volume demand for construction and security sectors.

Q: What industries benefit most from high speed roll forming machines?

A: Automotive, construction, and HVAC industries rely on these machines for roofing, cladding, and structural components. They are also essential for manufacturing garage doors, shelving, and solar panel frames. High-speed output supports just-in-time production workflows.

Q: How often should maintenance be performed on high speed roll forming machines?

A: Routine checks on rollers, hydraulic systems, and alignment should occur weekly. Lubrication of critical components is recommended every 500 operating hours. Annual overhauls ensure longevity and prevent production delays due to wear.