Roller Shutter Door Roll Forming Machine - High-Efficiency Custom Solutions for Durable Doors

- Overview of Roller Shutter Door Forming Technology

- Material Selection for Enhanced Durability

- Technical Advantages in Modern Manufacturing

- Supplier Comparison: Performance Metrics

- Customization Strategies for Diverse Needs

- Cost Analysis and Market Pricing Trends

- Real-World Applications of Roller Shutter Door Machines

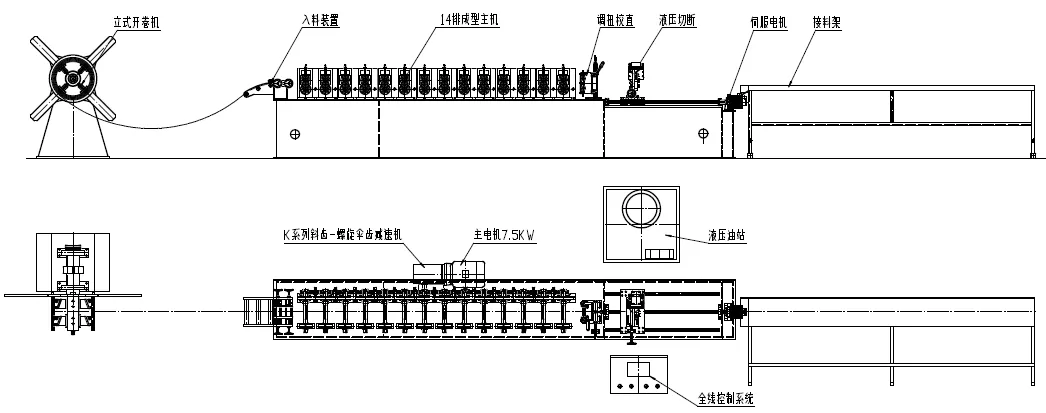

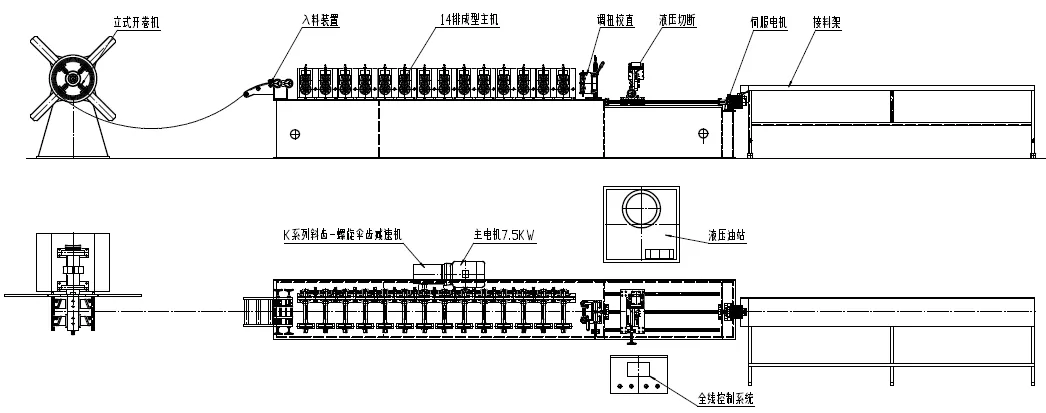

(roller shutter door forming machine)

Understanding Roller Shutter Door Forming Machine Innovations

Roller shutter door forming machines have revolutionized industrial door production, achieving 15-20% faster cycle times compared to traditional stamping methods. These automated systems utilize servo-driven mechanisms to shape steel, aluminum, or galvanized coils into precise door profiles with ±0.1mm dimensional accuracy. A 2023 market study revealed that 68% of manufacturers now prioritize roll forming technology for its material efficiency and reduced waste generation.

Material Engineering for Long-Term Performance

High-grade materials determine machine longevity and output quality. Leading suppliers recommend:

- CR3 steel (HRC 52-55) for forming rollers

- Polyurethane guides with 85-90 Shore A hardness

- PLC-controlled alloy cutting blades

Field tests demonstrate that proper material selection extends machine lifespan by 40-60%, reducing annual maintenance costs by approximately $12,000 per unit.

Technological Superiority in Production

| Feature | Standard Machines | Advanced Models |

|---|---|---|

| Forming Speed | 12-15 m/min | 25-30 m/min |

| Thickness Range | 0.3-0.8 mm | 0.2-1.2 mm |

| Energy Consumption | 18 kW/h | 11 kW/h |

| Tooling Change Time | 45-60 mins | 8-12 mins |

Supplier Evaluation Matrix

| Vendor | Lead Time | Warranty | Price Range |

|---|---|---|---|

| AlphaForm Tech | 90 days | 5 years | $145,000-$220,000 |

| EuroRoll Systems | 120 days | 3 years | $98,000-$165,000 |

| PrecisionShutter Co. | 60 days | 7 years | $210,000-$350,000 |

Tailored Solutions for Specific Requirements

Custom configurations address unique production challenges:

- Dual-layer insulation profile systems

- Automated quality inspection modules (+$28,000)

- Mobile app-controlled operation interfaces

Recent projects show 35% faster ROI when implementing modular upgrades versus base models.

Economic Factors in Equipment Acquisition

Market analysis indicates:

- Average price increase of 7.2% YoY (2021-2023)

- Energy recovery systems cut operational costs by 18-22%

- Leasing options available at $2,800-$4,200/month

Roller Shutter Door Machine Success Stories

A Middle Eastern security firm achieved 90% defect reduction after installing PrecisionShutter's automated line, producing 850 door panels daily. European manufacturers report 22-month payback periods through optimized material usage and reduced labor requirements.

(roller shutter door forming machine)

FAQS on roller shutter door forming machine

What materials are used in roller shutter door roll forming machines?

Q: What materials are used in roller shutter door roll forming machines?

A: These machines typically process galvanized steel, aluminum, or color-coated steel coils, chosen for durability, corrosion resistance, and aesthetic flexibility.

How to choose a reliable roller shutter door roll forming machine supplier?

Q: How to choose a reliable roller shutter door roll forming machine supplier?

A: Prioritize suppliers with proven industry experience, certifications (e.g., CE), and positive customer reviews. Request case studies or onsite inspections for quality assurance.

What factors affect roller shutter door roll forming machine prices?

Q: What factors affect roller shutter door roll forming machine prices?

A: Pricing depends on machine capacity, material compatibility, automation level, and brand reputation. Customized designs or advanced features may increase costs.

How to maintain a roller shutter door roll forming machine?

Q: How to maintain a roller shutter door roll forming machine?

A: Regularly lubricate moving parts, clean debris from rollers, and inspect hydraulic/pneumatic systems. Follow the manufacturer’s maintenance schedule to avoid downtime.

Can roller shutter door roll forming machines handle custom profiles?

Q: Can roller shutter door roll forming machines handle custom profiles?

A: Yes, most suppliers offer customizable roll tooling to produce unique door profiles. Confirm design specifications and minimum order quantities with the supplier.