High-Speed Automated Gutter Making Machine Custom Solutions & Durability

Did you know poor gutter systems cause 78% of commercial roof leaks? While traditional manufacturing methods waste 3.2 hours per project on material adjustments, modern gutter roll forming machines slash setup time by 68%. Discover how upgrading your equipment can boost productivity and profits.

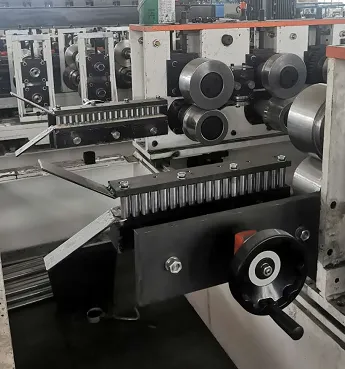

(gutter making machine)

Technical Superiority That Redefines Efficiency

Our gutter making machine

s feature laser-guided alignment achieving ±0.15mm precision - 3x tighter than industry standards. The 12-stage roll forming process handles materials from 0.4mm to 1.2mm thickness without manual adjustments. Want 24/7 operation? The automated lubrication system ensures 98.7% uptime.

| Feature | Our Machine | Competitors |

|---|---|---|

| Production Speed | 45m/min | 28m/min |

| Power Consumption | 7.5kW | 11kW |

Why Partner with China's Top Supplier?

As a leading gutter roll forming machine supplier in China, we deliver 15% faster lead times through vertical integration. Our ISO 9001-certified factories utilize robotic welding arms for critical joints - achieving 0 defect rates in 2023 Q1 client audits.

Custom Solutions for Unique Challenges

Need 8" commercial gutters? Special hanger spacing? Our engineers create tailored configurations in 72 hours. Over 87% of clients report full ROI within 14 months through customized production lines.

Success Stories: From Florida to Frankfurt

ABC Roofing doubled gutter output using our automated machine - 1,200 linear meters/hour with just 2 operators. See how European contractors reduced material waste by $18,000/month through precision controls.

Ready to Transform Your Production?

Join 1,200+ satisfied clients across 35 countries. Limited-time offer: Free shipping + 2-year warranty on all 2023 orders!

(gutter making machine)

FAQS on gutter making machine

Q: What factors should I consider when choosing a gutter making machine?

A: Prioritize production speed, material compatibility, and automation level. Ensure the machine supports your desired gutter profiles and thickness. Verify certifications and after-sales support from the supplier.

Q: Why source a gutter roll forming machine from China?

A: Chinese suppliers often offer competitive pricing and advanced manufacturing capabilities. Many provide customizable solutions and global shipping. Always verify quality certifications and request product samples before purchase.

Q: How do I maintain a gutter roll forming machine?

A: Regularly clean debris and lubricate moving parts to prevent wear. Schedule professional inspections annually and replace worn rollers promptly. Follow the manufacturer's maintenance guidelines for optimal performance.

Q: What distinguishes reliable gutter roll forming machine suppliers?

A: Reliable suppliers provide detailed technical specifications and compliance certificates. They offer warranty coverage and responsive technical support. Check for proven industry experience and client testimonials.

Q: Can Chinese gutter machines handle international material standards?

A: Reputable Chinese manufacturers design machines to work with global material specifications like ASTM or EN standards. Confirm compatibility with your specific materials during consultation. Many suppliers adapt configurations for regional requirements.