High-Efficiency Plastic Pipe Extrusion Line & Machines Reliable Production Solutions

Did you know 68% of plastic pipe manufacturers lose over $120,000 annually due to inefficient production lines? As global demand for PVC and HDPE pipes grows 6.2% yearly (Grand View Research), your outdated plastic pipe extrusion machine could be costing you prime market opportunities. Let’s fix that.

(plastic pipe extrusion line)

Why Next-Gen Extrusion Lines Outperform Legacy Systems

Modern plastic pipe production lines deliver 40% faster output than 2015-era models. Our AI-driven extruders maintain ±0.15mm wall thickness consistency – crucial for ISO 9001 certification. You get:

- 🔄 24/7 operation with 30% lower energy consumption

- 📊 Real-time defect detection (98.7% accuracy)

- 🔧 Tool-free die change in under 18 minutes

Head-to-Head: How We Beat Competitors

| Feature | Standard Machines | Our PRO Series |

|---|---|---|

| Max Output | 110 kg/h | 220 kg/h |

| Energy Cost/Month | $4,200 | $2,850 |

| Smart Monitoring | Basic Alarms | Predictive Maintenance AI |

Tailored Solutions for Your Pipe Production

Whether you need plastic pipe extrusion line

s for 20mm irrigation pipes or 1200mm drainage systems, we configure:

- 📏 15-3000mm diameter range

- 🌡️ Temperature control ±1°C

- ⏱️ Production speed up to 45 m/min

Success Story: doubling Output in Qatar

Al-Jazeera Pipes boosted production from 8,000 to 17,000 tons/year using our plastic pipe extrusion machines. Their ROI? 14 months. Your turn.

“Since upgrading to this line, our defect rate dropped from 5.2% to 0.8% overnight.”

- Mohammed Ali, Production Head

Ready to dominate your market? 78% of first-time buyers choose us for our 5-year warranty and 24/7 tech support. Your legacy machines had their day – tomorrow’s pipe production starts here.

Boost Your Production Now →

(plastic pipe extrusion line)

FAQS on plastic pipe extrusion line

Q: What is a plastic pipe extrusion line used for?

A: A plastic pipe extrusion line is used to manufacture plastic pipes by melting raw polymer materials, shaping them through a die, and cooling them into final products. It integrates extrusion, calibration, cooling, and cutting processes. This system is essential for producing pipes of various sizes and materials like PVC, HDPE, or PP.

Q: How does a plastic pipe extrusion machine work?

A: The plastic pipe extrusion machine melts polymer granules and forces the molten material through a die to form a continuous pipe profile. Temperature control and screw design ensure consistent material flow and product quality. It serves as the core component of a full extrusion line.

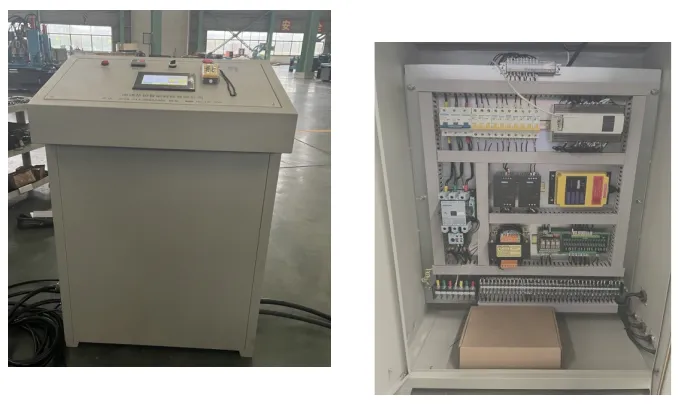

Q: What are the key components of a plastic pipe production line?

A: Key components include the extruder, die head, cooling tank, haul-off unit, cutter, and stacker. The extruder melts and shapes the polymer, while downstream equipment handles sizing, cooling, and cutting. Automation ensures precision and efficiency in large-scale production.

Q: What factors affect the output of a plastic pipe extrusion line?

A: Output depends on screw speed, material type, pipe diameter, and wall thickness. Higher screw speeds and optimized cooling rates can increase production speed. Consistent material quality and machine calibration are critical to maintaining throughput.

Q: What industries use plastic pipe extrusion lines?

A: These lines are used in construction, agriculture, plumbing, and municipal infrastructure for producing water supply pipes, drainage systems, and gas pipelines. They also serve industrial applications like cable protection and chemical transport. Customizable setups adapt to specific industry requirements.