Project evaluation

1.1. General information:

|

Raw material & formulation |

PVC resin powder & CaCo3, Lubricant; Stabilizers; Pigments; Antioxidants |

|

Melt capacity |

250 - 350kg/h (depending upon pipe dimension and reference material) |

|

Central height: |

1m |

|

Picture of final product |

|

1.2.Pipe species and size list:

|

No. |

O.D. (mm) |

Pressure Class |

Pressure Class |

|

1 |

20 |

PN0.63 |

PN1.0 |

|

2 |

25 |

PN0.63 |

PN1.0 |

|

3 |

32 |

PN0.63 |

PN1.0 |

|

4 |

40 |

PN0.63 |

PN1.0 |

|

5 |

50 |

PN0.63 |

PN1.0 |

|

6 |

63 |

PN0.63 |

PN1.0 |

|

7 |

75 |

PN0.63 |

PN1.0 |

|

8 |

90 |

PN0.63 |

PN1.0 |

|

9 |

110 |

PN0.63 |

PN1.0 |

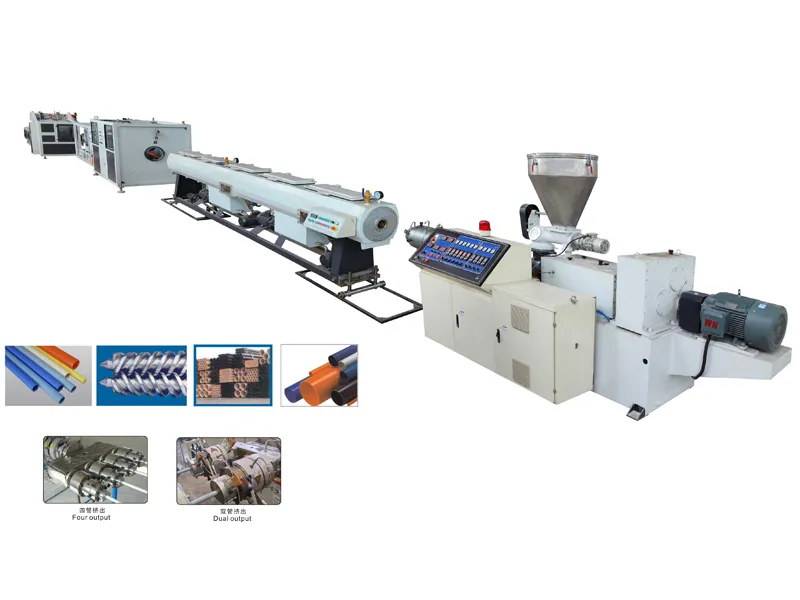

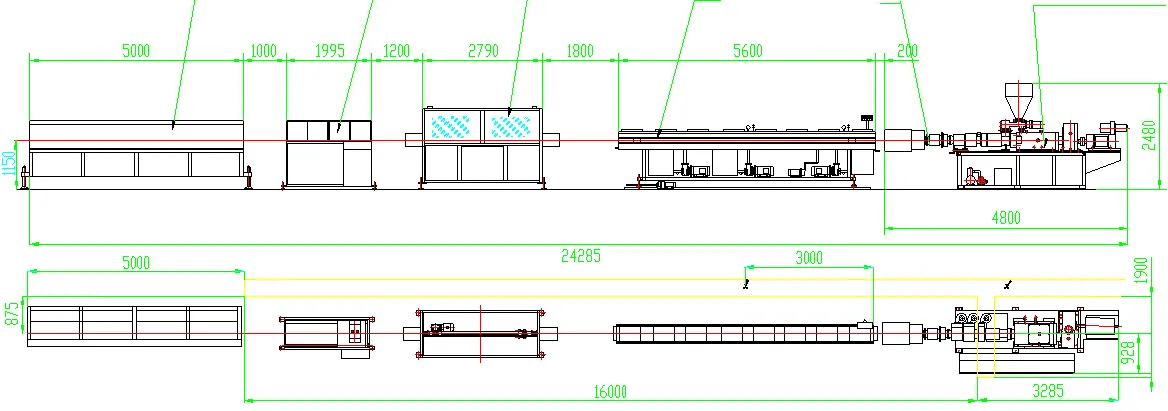

1.3. Flow line picture

1.4. Machine list

|

No. |

Machine |

Qty. |

|

1 |

Screw conveyor(for SJZ65/132 extruder) |

1set |

|

2 |

SJZ65/132 conical twin-screw extruder |

1set |

|

3 |

Mould for drain pipe (20-50、63-110mm) |

2 sets |

|

4 |

Vacuum calibration tank |

1set |

|

5 |

Haul-off |

1set |

|

6 |

Planetary cutter |

1set |

|

7 |

Stacker |

1set |

|

8 |

Screw conveyor(for 300/600 Mixer unit) |

1set |

|

9 |

SRL-Z300/600 Mixer unit |

1set |

|

10 |

20-110mm Pipe-expanding machine(R type、U type) |

1set |

2.1 Technical data

|

No. |

Name |

Photo of machine |

Technical specifications |

|

1 |

Screw conveyor |

|

Capacity:>300kg/h |

|

Rated transmission capacity: 500-1000kg/h Motor power: 2.2KW Pusher motor: 0.75kw Pipe diameter: φ102mm Touch raw materials are made by stainless steel |

|||

|

2 |

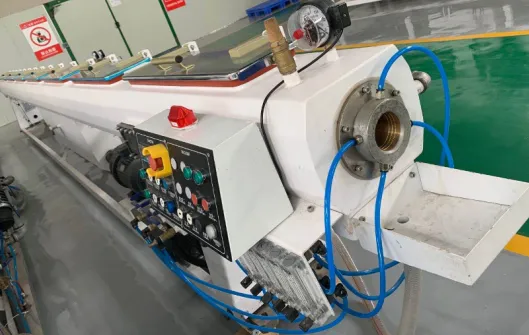

SJZ65/132 conical twin-screw extruder

|

|

Screw Barrel Driving motor Feeding system Vacuum system |

|

Screw: Diameter conical 65/ 132 mm for PVC drainpipe and water supply pipe. Material of screw: 38CrMoAl Surface treatment: Nitriding processing, thickness: 0.4 ~ 0,6mm, Polishing Rigidity:(HV)740-940 Surface roughness: Ra≤0.8um Rotating speed (counter rotating): 1-34.7 rpm/min Barrel: Diameter conical 65/132 Inner processing: nitrided with thickness: 0.4~ 0.7mm Rigidity:(HV)940-1100 Inner surface roughness: Ra≤1.6um Heating zones: 4 Heating mode: Cast alumina + stainless steel covering Heating power: 22kw Cooling mode: Air fans: 3 Sets Driving motor: Motor power: 37KW Type of motor = AC Feeding system: Gravity and screw dosing feeding system With stainless steel hopper Dosing feeding system: Motor: 0.75KW Feeding sleeve with circular water cooling Vacuum dehumidifying system: Vacuum pump: 1 set Vacuum degree = 0 ~ 0.075 Mpa Adaptor: (Interflow Section): Material: #40steel Chrome plated, inner convergent flow type Connection method with die: clamping block + bolt Pressure melt sensor and thermocouple Main electric part supplier : Inverter: ABB Contactor: Schneider Relay: Omron Temperature controller: Omron Self protective system: Over current protective of motor Over pressure protective of screw. |

|||

|

3 |

Mould

|

|

Including calibration sleeve |

|

Material: Made by 40Cr. Inner surface polished Diameter spec: Ф(20、25、32、40、50、63、75、90、110)mm Heating: QTY. of heating zone:10 Heating power:26KW |

|||

|

4 |

Vacuum calibration tank |

|

Vacuum system Water spray system Moving system |

|

Dimensions: Length: 5600mm Vacuum pump: Power: 3KW Water pump: Power: 4 KW Three directions adjustment: Forward and Backward moving: 0.75 KW motor Range: ±400mm Up and down: left and right manually adjusted Range: Up and Down: ±50mm Leftward and Rightward moving: ±50mm Tank material: Stainless steel Tank cover material: Duralumin Seal: adopt silica gel anti-friction panel and Q235 galvanized panel Inner pipe support: Nylon wheel Water temperature and level control: automatic control system by electric and stainless steel floating ball Vacuum gauge:0.03-0.06Mpa Spraying nozzle: ABS |

|||

|

5 |

Haul off |

|

Three claws Haul-off Independent control system |

|

Haul off unit (2 claws). Claw length: 1300mm Haul-off speed: 1-10m/min Power:1.1KW×2 Pneumatic clamping: adopt anti-friction rubber block Electric part: Inverter: Hitachi or ABB Low voltage electric parts: LG or Schneider Length detecting: encoder |

|||

|

6 |

Cutter |

|

Scrap collecting device; Independent control system

|

|

Cutter Integration installed in monobloc system (haul-off and cut off). Length count: encoder Cutting saw: steel alloy, specific for cutting U-PVC pipe. Equipped with rubber clamping block for accurate cutting. Motor power: 1.5KW Equipped with a closed dust-collector With scrap collecting device Possibility of manual operation |

|||

|

7 |

Stacker |

|

Discharging: Pneumatic |

|

Length: 5,000mm With screws to adjust the height range: 0 ~ 180mm |

|||

|

8. Screw conveyor |

Technical specifications |

|

Capacity:>300kg/h Motor power: 2.2KW Pusher motor: 0.75kw Pipe diameter: φ102mm Touch raw materials are made by stainless steel |

|

9.SRL-Z300/600 Mixer unit |

Technical data |

||

|

Mechanical parts |

|||

|

Hot-mixing |

Cold mixing |

||

|

Total volume(L) |

300 |

Total volume(L) |

600 |

|

Effective volume(L) |

225 |

Effective volume(L) |

380 |

|

batch(KG) |

105 |

batch(KG) |

105 |

|

Mixing time(min) |

8-10 |

Mixing time(min) |

8-10 |

|

capacity(KG/H) |

450-550 |

capacity(KG/H) |

450-550 |

|

Heating method |

Self-fiction |

Cooling method |

Interlayern water, cooling water ring |

|

Blade max rotation speed(rpm) |

465/930 |

Blade max rotation speed(rpm) |

100 |

|

Electrical parts |

|||

|

Hot mixing motor power(KW) |

55kw |

||

|

Speed controller for Hot mixing motor |

ABB |

||

|

Cold mixing motor power(KW) |

7.5kw |

||

|

Air switch |

LS |

||

|

Breaker |

LS |

||

|

Relay |

Schneider |

||

|

Button |

DELIXI |

||

|

|||

|

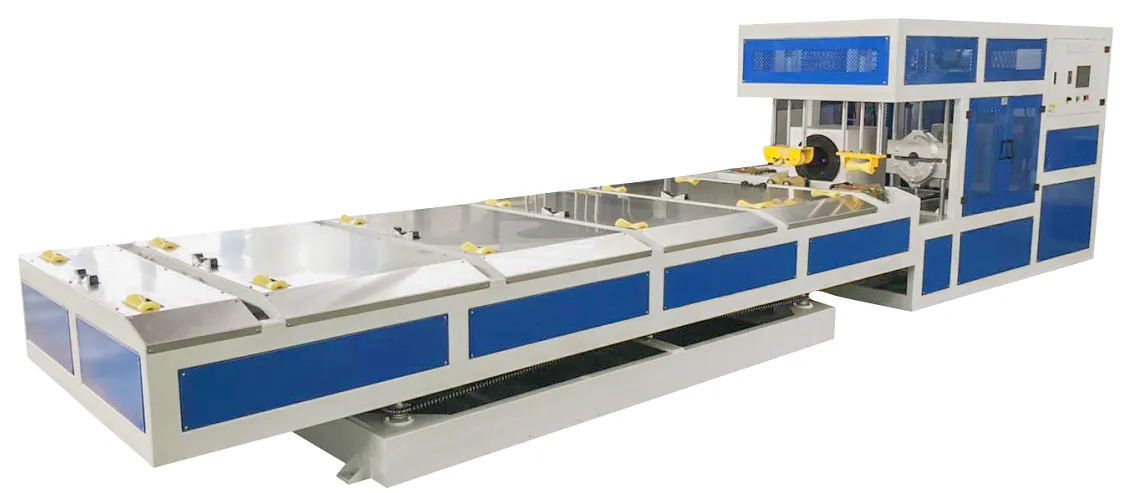

10.Pipe-expanding machine On line |

Technical parameter |

|

Scope of flaring OD: |

OD:Φ20-110mm |

|

Flared length: |

4-6 mm PVC pipe |

|

Flared solvent-based |

accepting port |

|

Heating mode |

Single oven ,Electric tube heating,Rotation heating |

|

Heating zone |

1 pc |

|

Cooling mode |

air cooled |

|

Dimension |

7800×1100×2200mm |

|

The total power of the enlargement machine |

15kw |

|

Heating power inside and outside the furnace |

8kw |

|

The maximum gas pressure of the flushing machine |

0.4MPa |

|

Water supply pressure |

0.2-0.3Mpa |

|

U type: 20、25、32、40、50、63、75、90、110mm R type: 50、63、75、90、110mm |

|

|

|