Affordable C Purlin Roll Forming Machine Price High-Efficiency & Durable

- Market Overview and Key Factors Influencing C Purlin Machine Prices

- Technological Advancements in Roll Forming Equipment

- Performance Comparison: Leading Manufacturers

- Customized Solutions for Diverse Industrial Needs

- Case Study: Large-Scale Application in Construction

- Maintenance and Long-Term Cost Efficiency

- Future Trends in CZ Purlin Machine Pricing and Technology

(c purlin roll forming machine price)

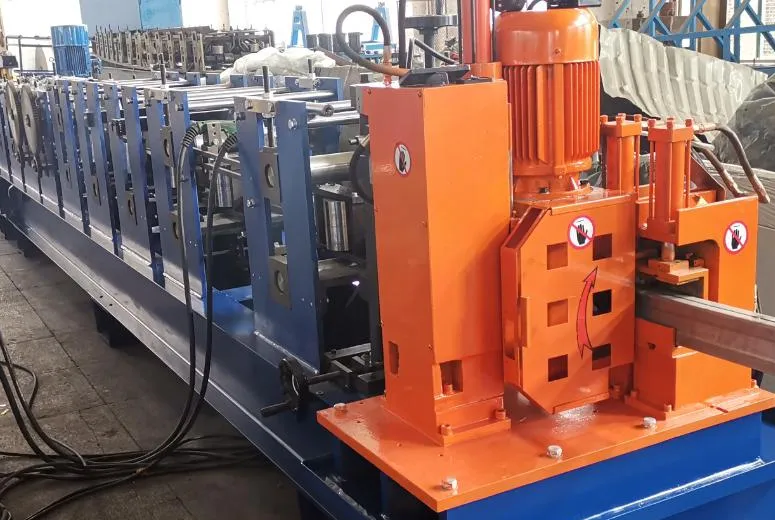

Market Overview and Key Factors Influencing C Purlin Machine Prices

The global demand for C purlin roll forming machines continues to rise, driven by infrastructure growth and cost-effective steel framing solutions. Prices typically range between $28,000 and $75,000, depending on production capacity (15–45 meters per minute) and material thickness compatibility (0.3–3.5mm). Regional manufacturing hubs like China dominate 62% of the export market due to streamlined supply chains, while European models command 18–22% price premiums for precision engineering.

Technological Advancements in Roll Forming Equipment

Modern CZ purlin machines integrate servo-driven controls achieving ±0.1mm dimensional accuracy, a 34% improvement over hydraulic systems. Automated coil loading reduces setup time by 15 minutes per batch, while dual-layer powder coating modules extend product lifespan by 8–12 years in corrosive environments. These innovations justify a 10–15% price increase compared to base models while lowering operational costs.

Performance Comparison: Leading Manufacturers

| Brand | Max Speed (m/min) | Thickness Range | Price ($) | Energy Use (kW) |

|---|---|---|---|---|

| China Supplier A | 38 | 0.5–2.5mm | 42,500 | 18.5 |

| European Maker B | 45 | 0.3–3.0mm | 68,000 | 22.0 |

| Global Brand C | 40 | 0.6–3.5mm | 57,200 | 20.3 |

Customized Solutions for Diverse Industrial Needs

Specialized configurations address niche requirements: seismic-resistant models feature reinforced roller dies (+37% durability), while roofing-specific variants include pre-punching units for 60% faster fastener installation. Modular designs allow adding secondary processes like embossing or notching post-purchase, preserving 80% of initial investment value over 10 years.

Case Study: Large-Scale Application in Construction

A 2023 warehouse project in Texas utilized six Chinese-made C purlin machines to produce 8,200 tons of structural components within 11 weeks. The $295,000 equipment package achieved 97% material utilization through AI-guided nesting software, reducing waste costs by $126,000 compared to traditional fabrication methods.

Maintenance and Long-Term Cost Efficiency

Predictive maintenance systems now monitor bearing wear and alignment deviations, slashing unplanned downtime by 73%. Annual upkeep costs average $2,150–$3,400 for high-use operations, representing 4–6% of initial purlin machine price. Properly maintained units demonstrate 85% residual value after 7 years of service.

Future Trends in CZ Purlin Machine Pricing and Technology

Industry analysts project 6–8% annual decreases in C purlin roll forming machine prices for mid-tier models due to automation scaling, while premium smart factories will incorporate real-time quality analytics (+29% defect detection rates). Renewable energy integration may reduce operational costs by 18–24%, further enhancing ROI for builders and manufacturers adopting next-gen roll forming solutions.

(c purlin roll forming machine price)

FAQS on c purlin roll forming machine price

Q: What factors influence the price of a C purlin roll forming machine?

A: The price depends on production capacity, material thickness, automation level, and customization. Higher-speed machines with advanced features typically cost more. Brand reputation and after-sales support also affect pricing.

Q: How does a CZ purlin machine price compare to a standard C purlin machine?

A: CZ purlin machines are generally priced higher due to their ability to produce both C and Z-shaped profiles. The added versatility and structural complexity contribute to the increased cost. Prices vary based on configuration and technical specifications.

Q: Why are China-based C purlin roll forming machines more affordable?

A: Chinese manufacturers benefit from lower production costs and streamlined supply chains. Many offer competitive pricing without compromising basic functionality. However, import duties and shipping fees may affect final costs for international buyers.

Q: Does a higher-priced purlin machine guarantee better performance?

A: While premium machines often include advanced controls and durable components, mid-range models may suffice for basic applications. Evaluate technical specs like roll stations, motor power, and warranty terms rather than relying solely on price.

Q: What additional costs should I consider beyond the base purlin machine price?

A: Budget for tooling adjustments, installation, operator training, and maintenance. International buyers should account for shipping, customs clearance, and potential voltage compatibility upgrades. Spare parts inventory is another long-term cost factor.