Revolutionizing Pipe Production: The Latest in Tube Mill Technology

A welded pipe production line is the backbone of modern tube manufacturing, providing a streamlined process for creating high-quality pipes used across a variety of industries. These production lines use advanced technology to produce pipes from steel coils through a process of forming, welding, and finishing, ensuring uniformity and precision in every pipe produced. The welded pipe production line is capable of handling a wide range of materials, including carbon steel, stainless steel, and alloy steel, making it adaptable to many industries, including construction, automotive, and oil and gas.

The efficiency of a welded pipe production line lies in its automated systems. It ensures high-speed production with minimal human intervention, reducing labor costs and improving consistency. The line includes advanced welding technology that produces high-quality welds, ensuring durability and reliability. With the ability to produce various pipe sizes and thicknesses, this production line offers flexibility that is crucial for businesses looking to meet diverse market demands. Whether you're making standard pipes or custom specifications, a welded pipe production line is indispensable for improving your manufacturing processes.

Furthermore, modern welded pipe production lines are designed with energy efficiency in mind. They incorporate systems that reduce waste and optimize resource usage, ensuring that the manufacturing process is not only fast and efficient but also environmentally responsible. Businesses that invest in these systems can significantly reduce operational costs while enhancing their competitiveness in the market.

ERW Pipe Making Machine: Key to High-Quality Pipe Production

The ERW pipe making machine (Electric Resistance Welding) is an essential tool in the manufacturing of pipes used for a variety of applications, from oil and gas pipelines to structural applications. This machine uses an innovative welding process that joins steel strips or coils at the edges, creating a high-strength, durable seam. The result is a pipe that is highly resistant to internal and external pressures, making it ideal for applications requiring both strength and flexibility.

One of the major advantages of the ERW pipe making machine is its ability to create pipes at a high rate of speed while maintaining high-quality welds. The precision of the welding process ensures that the pipes are consistent in size and shape, with minimal material waste. With the ERW pipe making machine, manufacturers can achieve faster turnaround times and lower production costs, which makes it highly cost-effective for large-scale production.

Another benefit is the versatility of the ERW pipe making machine. It can handle a variety of steel grades and pipe sizes, making it suitable for a wide range of industries. Whether you're producing pipes for the energy sector, construction, or automotive, the ERW pipe making machine is an essential piece of equipment for ensuring high-quality, reliable products.

Square Tube Welding Machine: Meeting Demands for Structural Integrity

A square tube welding machine is designed specifically for manufacturing square or rectangular tubes, which are used in structural applications where strength and durability are key. These machines are equipped with advanced welding technologies that ensure precision and quality. The square tube welding machine offers fast production speeds while maintaining a high level of accuracy, ensuring that every tube produced is square and uniform.

What sets the square tube welding machine apart is its ability to handle both thin and thick materials, allowing for flexibility in the types of projects it can support. From light gauge to heavy-duty steel, this machine can be adjusted to accommodate different material thicknesses, ensuring that all products meet the necessary strength and durability standards. The machine’s design is focused on reducing waste and improving material utilization, ensuring cost-efficiency during production.

Moreover, the square tube welding machine is often integrated into larger manufacturing systems, such as a welded pipe production line, providing manufacturers with a complete solution for producing high-quality pipes and tubes. With the right machine, companies can meet market demands for square tubes used in everything from furniture to industrial structures.

Tube Mill Line Manufacturers: Selecting the Best Equipment for Your Business

When considering investments in pipe and tube manufacturing, choosing the right tube mill line manufacturers is critical to ensuring the longevity and efficiency of your production process. The tube mill line manufacturers provide machines that are designed for high performance, durability, and flexibility in production. Whether you're producing welded pipes, square tubes, or specialty products, selecting a reliable manufacturer is key to meeting industry standards and improving productivity.

A top-tier tube mill line manufacturer will not only offer a wide range of machines that can be customized to meet specific production needs but will also provide comprehensive customer support, from installation to maintenance. They will guide you in choosing the best equipment for your production scale and material requirements. The reputation of tube mill line manufacturers is built on their ability to provide high-quality machines that produce consistent results, ensuring that your operations run smoothly and efficiently.

Investing in a tube mill line manufacturer with a solid track record of success ensures that you will receive a high-quality machine that is built to last. These manufacturers also understand the importance of continuous improvement, providing their customers with the latest technological advances to help optimize production and reduce downtime. For businesses looking to expand or enhance their pipe production capabilities, a reputable tube mill line manufacturer is the right partner for long-term success.

Tube Mill Machine Process: Streamlining Pipe Production

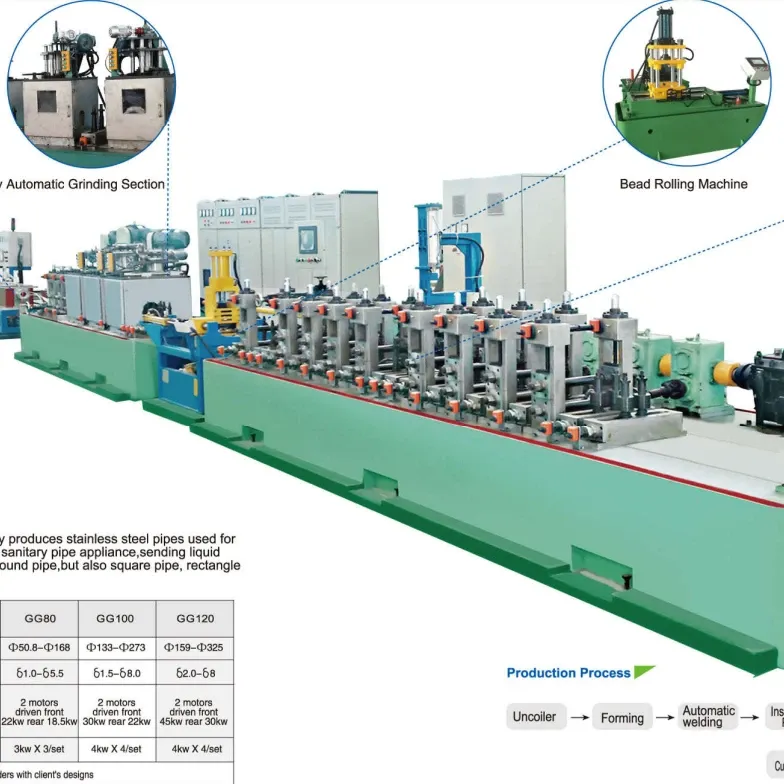

The tube mill machine process is the heart of any welded pipe production system, transforming raw materials like steel coils into finished pipes. This process involves multiple stages, including decoiling, forming, welding, sizing, and cutting to length. Each stage is critical to ensuring that the final product meets the necessary specifications for strength, size, and surface finish. The tube mill machine process is designed to be highly automated, reducing manual labor and improving the overall efficiency of the production line.

The process begins with the decoiling of a steel coil, which is fed into the tube mill machine for shaping. The material is then passed through a series of rollers that gradually form it into a tubular shape. At this point, the edges of the tube are welded together, typically using an electric resistance welding (ERW) process. The welded tube is then sized to ensure it meets the required diameter and wall thickness, before being cut to the desired length. The result is a high-quality, precise tube ready for use in a variety of applications.

By using the tube mill machine process, manufacturers can produce pipes and tubes with a high degree of consistency and precision. This process is not only fast but also cost-effective, as it reduces material waste and optimizes production speed. Additionally, modern tube mills are designed with advanced controls that allow for easy adjustments and monitoring, ensuring that the production process remains efficient and effective.

Tube Mill Line Manufacturers FAQs

What is a welded pipe production line?

A welded pipe production line is a manufacturing system used to produce welded pipes from steel coils. The process includes forming, welding, and finishing the pipe to ensure it meets specific requirements for strength, size, and quality.

How does an ERW pipe making machine work?

An ERW pipe making machine uses electric resistance welding to join the edges of a steel strip or coil, forming a pipe. The machine controls the welding process precisely, ensuring that the seams are strong and reliable, making it ideal for high-strength applications.

What are the uses of a square tube welding machine?

A square tube welding machine is used to produce square or rectangular tubes that are essential in structural applications, including construction and manufacturing. The machine ensures that the tubes are uniform in size and strength, making them perfect for a range of industries.

Why choose tube mill line manufacturers?

Tube mill line manufacturers offer high-quality, customizable equipment for producing a wide variety of pipes and tubes. By selecting a reputable manufacturer, you ensure that your equipment is efficient, durable, and capable of meeting the specific needs of your production line.

What is the tube mill machine process?

The tube mill machine process involves multiple stages, such as decoiling, forming, welding, sizing, and cutting, to turn steel coils into finished pipes. This automated process is designed to be highly efficient, producing pipes with precision and minimizing waste.

In conclusion, if your business is in the market for high-quality pipes and tubes, investing in a welded pipe production line, ERW pipe making machine, square tube welding machine, or a tube mill line will significantly enhance your production capabilities. These advanced machines are essential for any company looking to stay competitive in the ever-demanding world of pipe manufacturing. For more details and to explore the best options available for your business, visit our website today and take the first step toward optimizing your production line.