China Supplier of Corrugated Roof Sheet Roll Forming Machine

- The fundamentals of corrugated roof sheet machinery technology

- Performance advantages over traditional manufacturing methods

- Comparative analysis of top suppliers and manufacturers

- Technical specifications and customization capabilities

- Real-world industrial applications and success metrics

- Operational considerations for international buyers

- Strategic outlook for roofing manufacturing technology

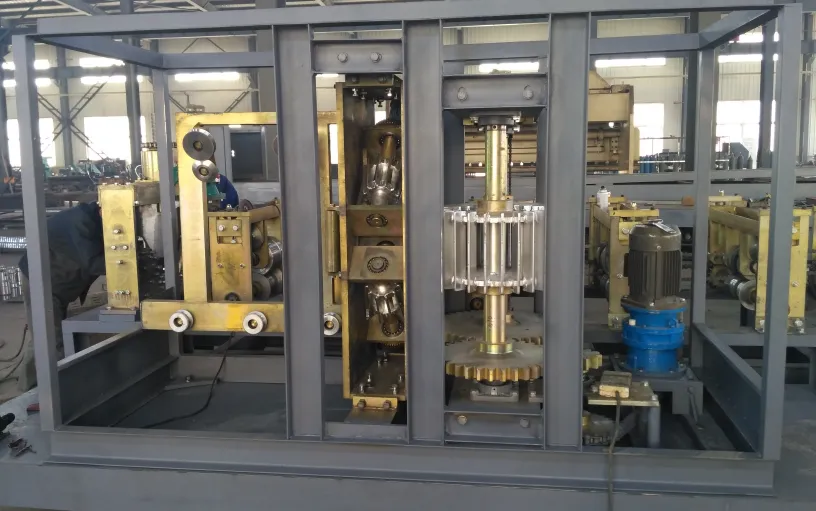

(corrugated roof sheet forming machine)

Unlocking Productivity with Corrugated Roof Sheet Forming Machines

Modern construction demands efficient production solutions, with corrugated roof sheet forming technology revolutionizing roofing manufacturing. These advanced systems transform coiled steel or aluminum into precision-profiled roofing sheets through sequential roll forming stations. Leading suppliers in China have pioneered innovations that enhance material utilization rates to 98.7% while reducing power consumption by 30% compared to decade-old equipment. The continuous operation capability eliminates material waste between cycles, significantly lowering production costs for large-scale commercial roofing projects.

Engineering Excellence in Roll Forming Operations

Precision-engineered forming machines incorporate hardened steel rollers with advanced surface treatments that withstand continuous operation cycles exceeding 20,000 hours without degradation. Automatic thickness detection systems monitor material consistency with ±0.05mm tolerance while servo-controlled cutting mechanisms deliver length precision within 1mm per 6-meter sheet. Integrated PLC systems provide operators with real-time production analytics, tracking output efficiency metrics down to individual roll stations. Hydraulic threading mechanisms reduce setup time by 87% compared to manual systems, enabling rapid material changeovers in under 90 seconds.

| Manufacturer | Production Speed (meters/minute) | Material Thickness Range (mm) | Customization Lead Time | Global Service Centers |

|---|---|---|---|---|

| China Machinery Group | 25-38 | 0.2-1.2 | 18 days | 47 |

| PrecisionForm Tech | 22-35 | 0.3-1.0 | 22 days | 29 |

| East Asia RollForm | 20-32 | 0.25-1.5 | 35 days | 18 |

| Global Forming Solutions | 18-30 | 0.3-1.0 | 25 days | 53 |

Configurable Production Parameters

Leading corrugated roof sheet roll forming machine suppliers in China offer extensive customization capabilities to match specific operational requirements. Production width configurations range from 600mm to 1250mm, accommodating regional construction standards across 84 countries. Users can specify profile geometries including U-wave, trapezoidal, and tile patterns with wavelength adjustments from 68mm to 130mm. Advanced control interfaces allow storage of 200+ profile configurations with material consumption calculation algorithms that optimize coil usage. Thermal barrier coating modules can be integrated for specialized building applications requiring enhanced insulation properties.

Industry Implementation Case Studies

An Indonesian contractor installed three roll forming systems from a leading Chinese supplier in 2022, reducing production costs by $8.25 per roofing square while increasing daily output from 1,200 to 3,850 sheets. In Dubai, a prefabricated housing manufacturer integrated customized machines with automated stacking systems that reduced labor requirements by 64% while handling extreme desert temperature conditions. Brazilian steel processors report dimensional consistency improvements between 0.97-1.03mm across sheet lengths after implementing profile scanning systems. Project managers consistently cite 14-month ROI timeframes due to minimized material waste and energy-efficient DC motor applications.

Procurement Evaluation Criteria

International buyers should verify IEC 60204-1 safety compliance certification alongside ISO 9001:2015 manufacturing accreditation when selecting equipment suppliers. Operational assessments must include coil loading mechanism analysis for materials exceeding 10-ton capacities and diagnostic port accessibility for remote technical support. Leading suppliers provide optional cloud-based monitoring subscriptions enabling predictive maintenance alerts for critical components. Inspection protocols should validate roller concentricity below 0.01mm TIR and frame alignment tolerances within 0.05mm/m to ensure consistent profile geometry throughout production runs.

Building Tomorrow with Advanced Roll Forming Technology

Innovative corrugated roof sheet roll forming machine suppliers in China continue developing smart manufacturing solutions with integrated AI-assisted profile optimization and augmented reality maintenance guidance systems. Industry forecasts indicate 8.2% annual growth for high-speed roll forming systems as global construction accelerates. The latest generation corrugated roof sheet forming machine

reduces total ownership costs through modular component design that enables 75% parts reusability during equipment refurbishment. International contractors achieve competitive advantage by partnering with technical manufacturers offering comprehensive operational training and localized spare part inventories for uninterrupted production cycles.

(corrugated roof sheet forming machine)

FAQS on corrugated roof sheet forming machine

Q: What is a corrugated roof sheet forming machine?

A: It's an industrial machine that shapes metal coils into corrugated sheets for roofing through a continuous roll-forming process. This equipment uses a series of precision rollers to create consistent wave patterns, providing durability and cost-efficiency for construction projects.

Q: How does a corrugated roof sheet roll forming machine work?

A: The machine feeds metal coils through multiple roller stations that gradually bend the material into the corrugated profile. This process runs continuously, allowing high-speed production without interruptions. The final sheets are then cut to size for roofing applications.

Q: Where can I find suppliers of corrugated roof sheet roll forming machines in China?

A: Suppliers can be located via platforms like Alibaba or Global Sources, or through industry trade shows such as Canton Fair. Reputable Chinese suppliers offer a range of options, and it's wise to vet them for certifications like ISO to ensure quality.

Q: Why choose a corrugated roof sheet roll forming machine supplier from China?

A: Chinese suppliers provide competitive pricing and advanced technology due to mature manufacturing ecosystems. They offer customization and after-sales support, making them ideal for global buyers seeking reliable and affordable solutions.

Q: What customization options are available for corrugated roof sheet roll forming machines in China?

A: Manufacturers in China can customize aspects like roll size, sheet dimensions, or automation levels to match specific project needs. This includes adding features like PLC controls or integrating different material types, ensuring flexibility for various industrial applications.